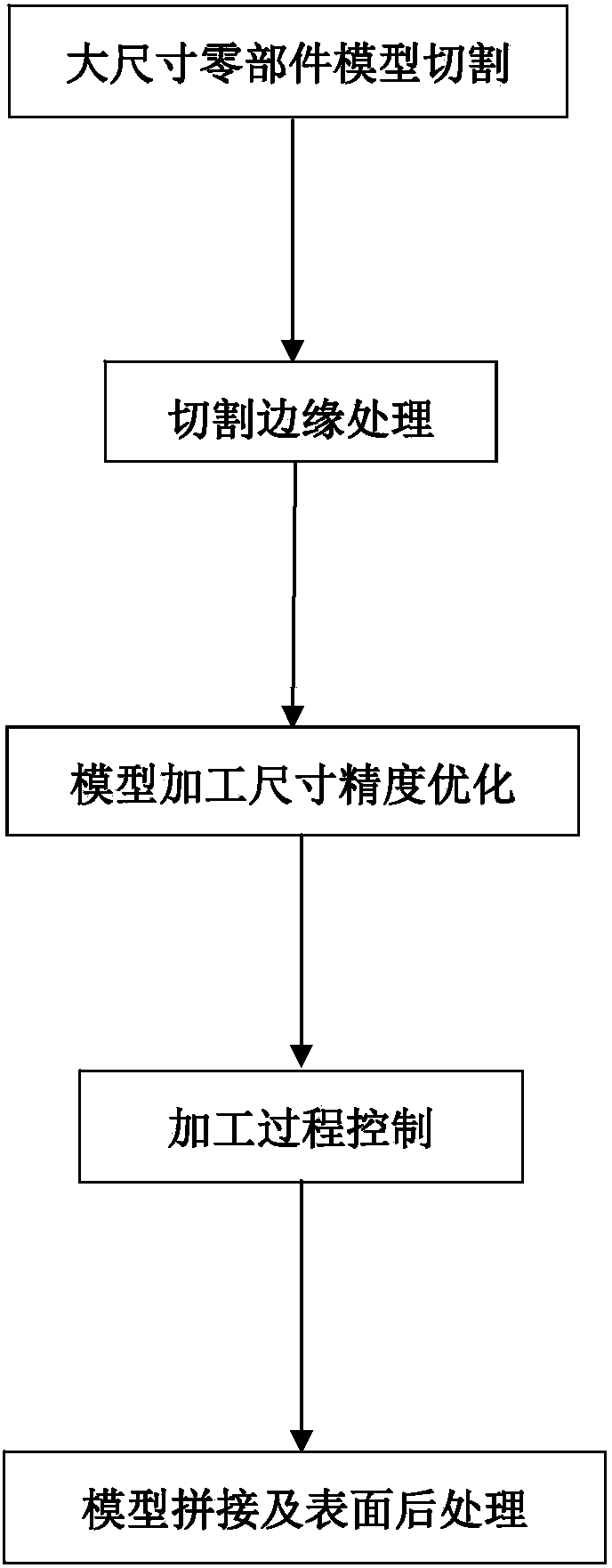

3D printing manufacturing method for large-size part

A technology of 3D printing and manufacturing methods, which is applied in the processing field of large-size parts, can solve the problems of restricting the manufacture of large-size parts, restricting free design, and restricting large-size parts, so as to achieve guaranteed performance and overall dimensional accuracy, good The effect of a fixed connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0064] A 3D printing manufacturing method for large-scale parts, the additive manufacturing equipment uses EOS P110, and the supporting software is Magics17.1 and PSW3.6. (1) Use the 3D model of the automobile engine intake manifold provided by the customer according to the customer's requirements. The size of the large-scale parts is 346mm×324mm×192mm, which is larger than the 325mm×250mm×220mm that can be processed by the P110 equipment, so it cannot be completed 3D model processing. (2) The shape of the pipe is complex, and the position of the straight pipe is selected for cutting, and the cutting method of the dovetail groove 5 is adopted, such as Figure 4 shown. (3) Carry out incision processing in Magics, and determine the placement of sub-parts, use RP-Tools to complete the slice production with a thickness of 0.1mm, and set optimized processing parameters in PSW software to ensure its dimensional accuracy. Among them, the spot compensation parameter obtained by the ...

example 2

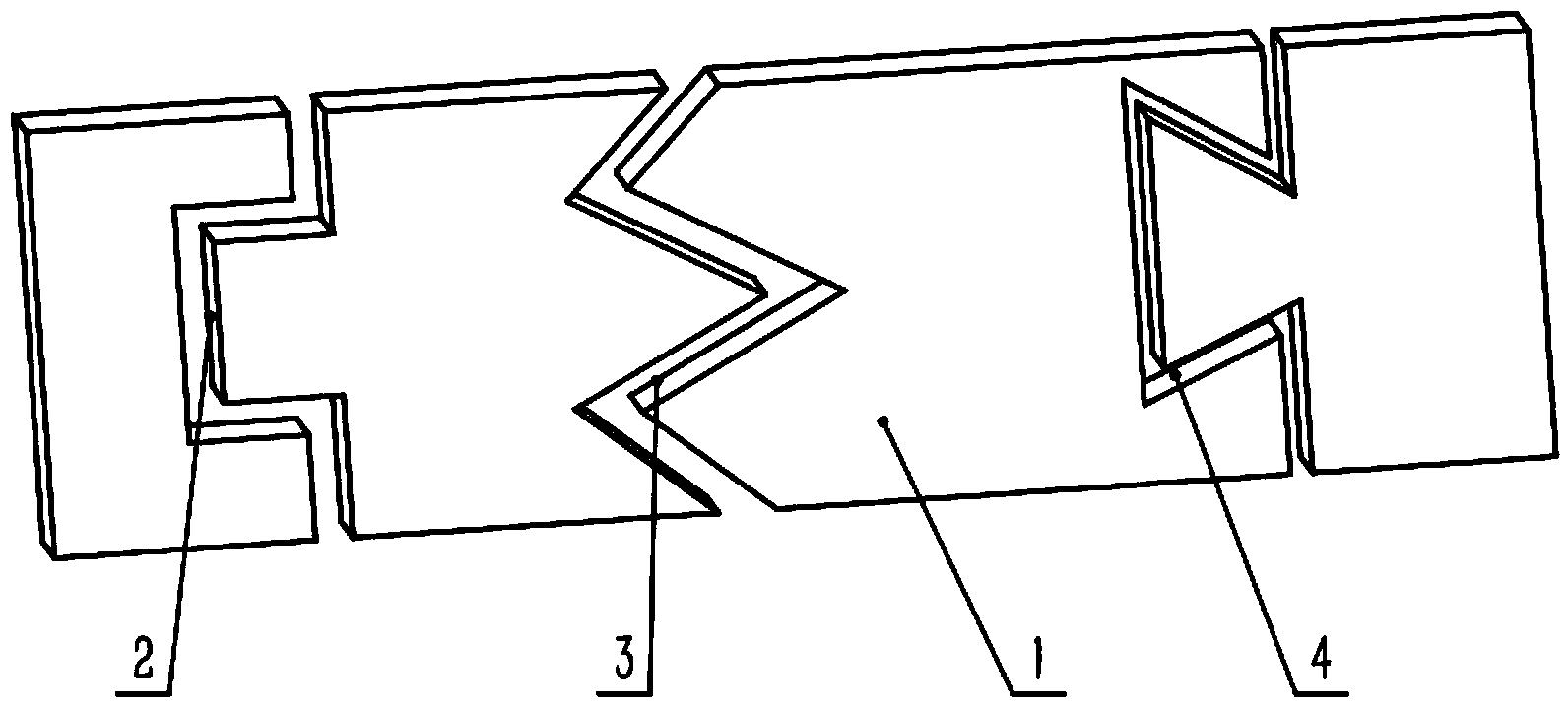

[0066] Such as Figure 5 As shown, the 3D printing manufacturing of the car dashboard shell, the specific manufacturing steps are similar to Example 1. The incision method adopts a rectangular incision 21 and a zigzag incision 31 in two different parts of the instrument panel shell 11 respectively.

example 3

[0068] Such as Figure 6 As shown, the specific manufacturing steps of the 3D printing manufacturing of large-scale pipes are similar to those of Examples 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com