Metal base ceramic phase reinforced alloy tool steel powder for 3D printing, preparation method and application thereof

An alloy tool steel, 3D printing technology, applied in metal processing equipment, additive manufacturing, process efficiency improvement, etc. Precise manufacturing, good hardness, the effect of eliminating macrosegregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

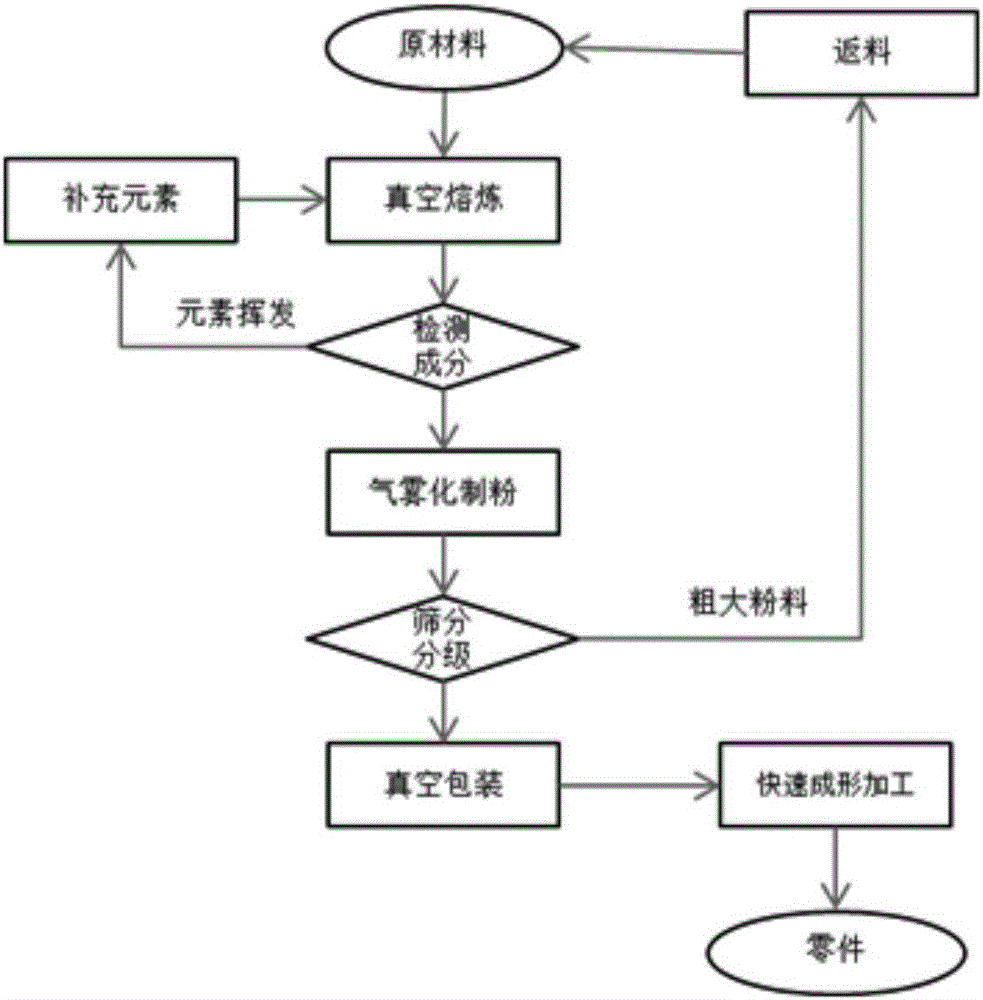

Image

Examples

Embodiment 1

[0032] A metal-based ceramic phase-reinforced alloy tool steel powder for 3D printing, the alloy tool steel powder contains elements and mass percentages: C, 0.8%; Si, 0.2%; Mn, 1%; Ni, 0.3%; Cr, 3%; Mo, 0.2%; V, 0.2%; W, 8%; Co, 1%; Nb, 0.5%; metal-based ceramic phase metal elements, 0.2%;

[0033] Preferably, the metallic element of the metal-based ceramic phase is one or more of Zr, Al, Be, Mg, Y, Zn, Ti, B, Ba, Ta, and the alloy tool steel powder is spherical or quasi-spherical, and the powder particles The diameter distribution is 15-80 μm, and the oxygen content is lower than 800 ppm, and the alloy tool steel powder is formed by gas atomization powder making. The metal elements of the metal-based ceramic phase are added through metal-based ceramic phase particles and / or pure elements, and the metal-based ceramic phase particles are one of metal carbide compounds, metal nitride compounds, metal oxides, and metal silicide compounds. one or more species.

[0034] The prep...

Embodiment 2

[0050] A metal-based ceramic phase-reinforced alloy tool steel powder for 3D printing, the alloy tool steel powder contains elements and mass percentages: C, 0.2%; Si, 0.6%; Mn, 0.5%; Ni, 0.6%; Cr, 12%; Mo, 2%; V, 1.5%; W, 0.3%; Co, 5%; Nb, 0.2%; metal-based ceramic phase metal elements, 0.2-8%; iron, the balance.

[0051] Preferably, the metallic element of the metal-based ceramic phase is one or more of Zr, Al, Be, Mg, Y, Zn, Ti, B, Ba, Ta, and the alloy tool steel powder is spherical or quasi-spherical, and the powder particles The diameter distribution is 15-80 μm, and the oxygen content is lower than 800ppm, and the alloy tool steel powder is formed by gas atomization, and the metal-based ceramic phase metal elements are added through metal-based ceramic phase particles and / or pure elements way, the metal-based ceramic phase particles are one or more of metal carbide compounds, metal nitride compounds, metal oxides, and metal silicide compounds.

[0052] The preparation ...

Embodiment 3

[0068] A metal-based ceramic phase-reinforced alloy tool steel powder for 3D printing, the alloy tool steel powder contains elements and mass percentages: C, 5%; Si, 1%; Mn, 0.1%; Ni, 1%; Cr, 25%; Mo, 15%; V, 14.5%; W, 15%; Co, 18%; Nb, 1%; metal-based ceramic phase metal elements, 0.2-8%; iron, the balance.

[0069] Preferably, the metallic element of the metal-based ceramic phase is one or more of Zr, Al, Be, Mg, Y, Zn, Ti, B, Ba, Ta, and the alloy tool steel powder is spherical or quasi-spherical, and the powder particles The diameter distribution is 15-80 μm, and the oxygen content is lower than 800 ppm, and the alloy tool steel powder is formed by gas atomization powder making. The metal elements of the metal-based ceramic phase are added through metal-based ceramic phase particles and / or pure elements, and the metal-based ceramic phase particles are one of metal carbide compounds, metal nitride compounds, metal oxides, and metal silicide compounds. one or more species. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com