Welding method for sintered NdFeB permanent magnets

A welding method and permanent magnet technology, applied in the direction of welding medium, welding equipment, welding/welding/cutting items, etc., can solve the problems of increasing irreversible loss, affecting magnetic structure or crystal structure, large internal stress, etc., to increase production process cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] According to the N40SH grade, the material ratio is carried out, and then the "scale" is obtained by alloying smelting and quick-setting process. The alloy flakes are powdered by a jet mill, and then shaped under a magnetic field. The formed billet is sintered in a sintering furnace at a temperature of 1090°C to 1100°C to obtain a full-density blank.

[0037] (1) Cut and process the sintered N40SH magnet hair into 9×3×2.5 blocks, put rare earth-iron-copper-silicon brazing material between the two processed magnets and compact them;

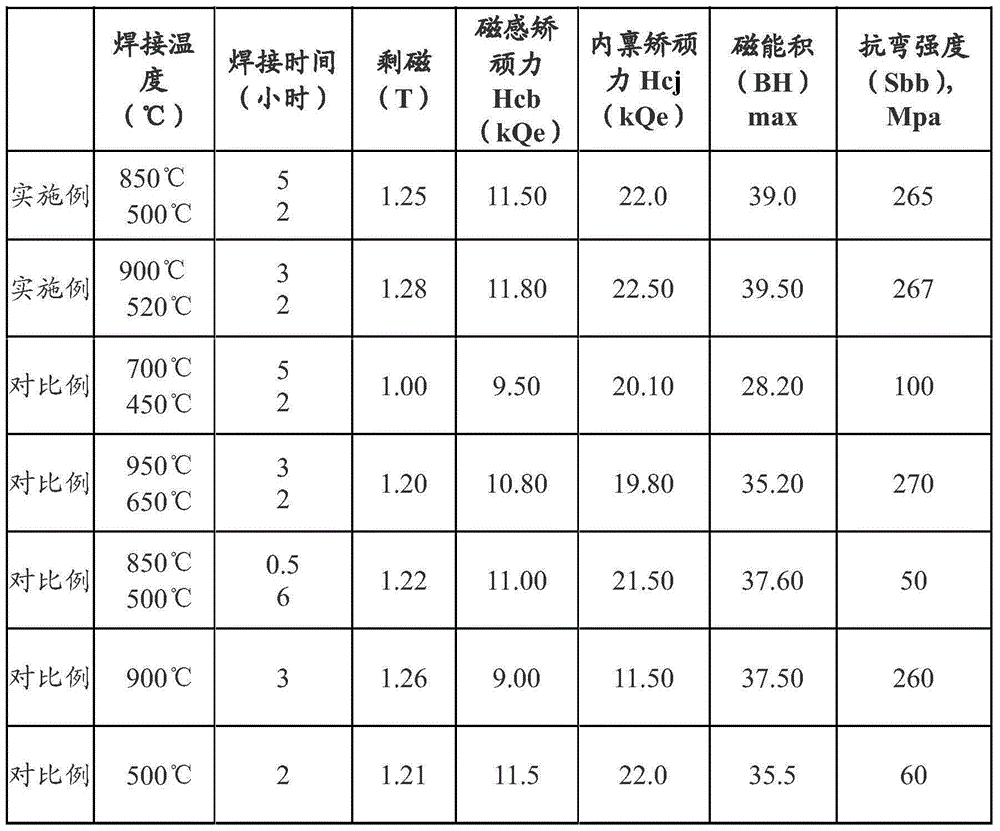

[0038] (2) Then put it in a tempering furnace, and perform brazing and tempering heat treatment between 850°C / 5 hours and 500°C / 2 hours, 900°C / 3 hours and 520°C / 2 hours, and finally get welded into 18 ×6×5 N40SH-NdFeB sintered magnets.

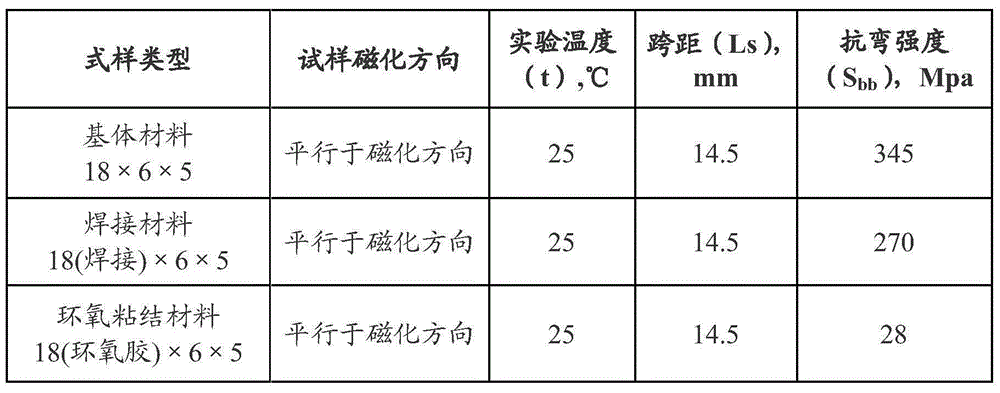

[0039] The bending strength measurement of the welded magnet and the comparison data of the epoxy resin bonded magnet with the same size are listed in Table 2.

[0040] For further illustration, the resu...

Embodiment 2

[0047] According to the N50H grade, the material ratio is carried out, and then the "scale" is obtained by alloying smelting and quick-setting process. The alloy flakes are powdered by a jet mill, and then shaped under a magnetic field. The formed billet is sintered in a sintering furnace at a temperature of 1090°C to 1100°C to obtain a full-density blank.

[0048] (1) Cut and process the sintered N50H magnet into 9×3×2.5 blocks, put rare earth-iron-copper-silicon brazing material between the two processed magnets and compact them;

[0049] (2) Then put it in a tempering furnace, and perform brazing and tempering heat treatment between 850°C / 5 hours and 500°C / 2 hours, 900°C / 3 hours and 520°C / 2 hours, and finally obtain a welded 18 ×6×5 N50H-NdFeB sintered magnets.

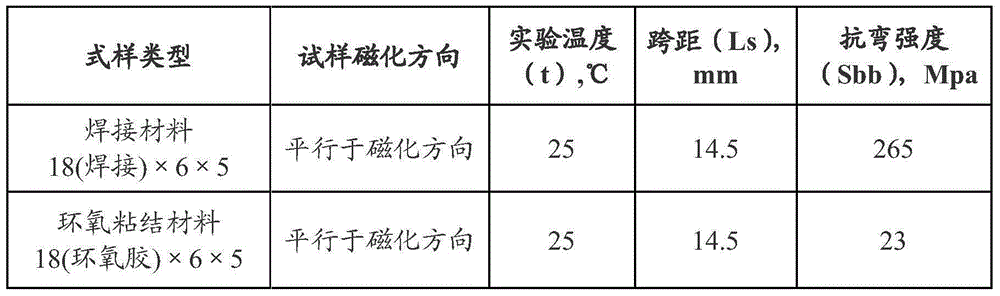

[0050] The bending strength measurement of the welded magnet and the comparative data of the epoxy resin bonded magnet are listed in Table 4.

[0051] For further illustration, the results of the welding magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com