NdFeB alloy vacuum melting method

A technology of vacuum smelting and vacuum induction smelting, which is applied in the field of vacuum smelting of NdFeB alloys, can solve the problems of affecting magnetic properties, great influence of ultimate vacuum degree, unsuitable for NdFeB magnet production, etc., and achieves the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

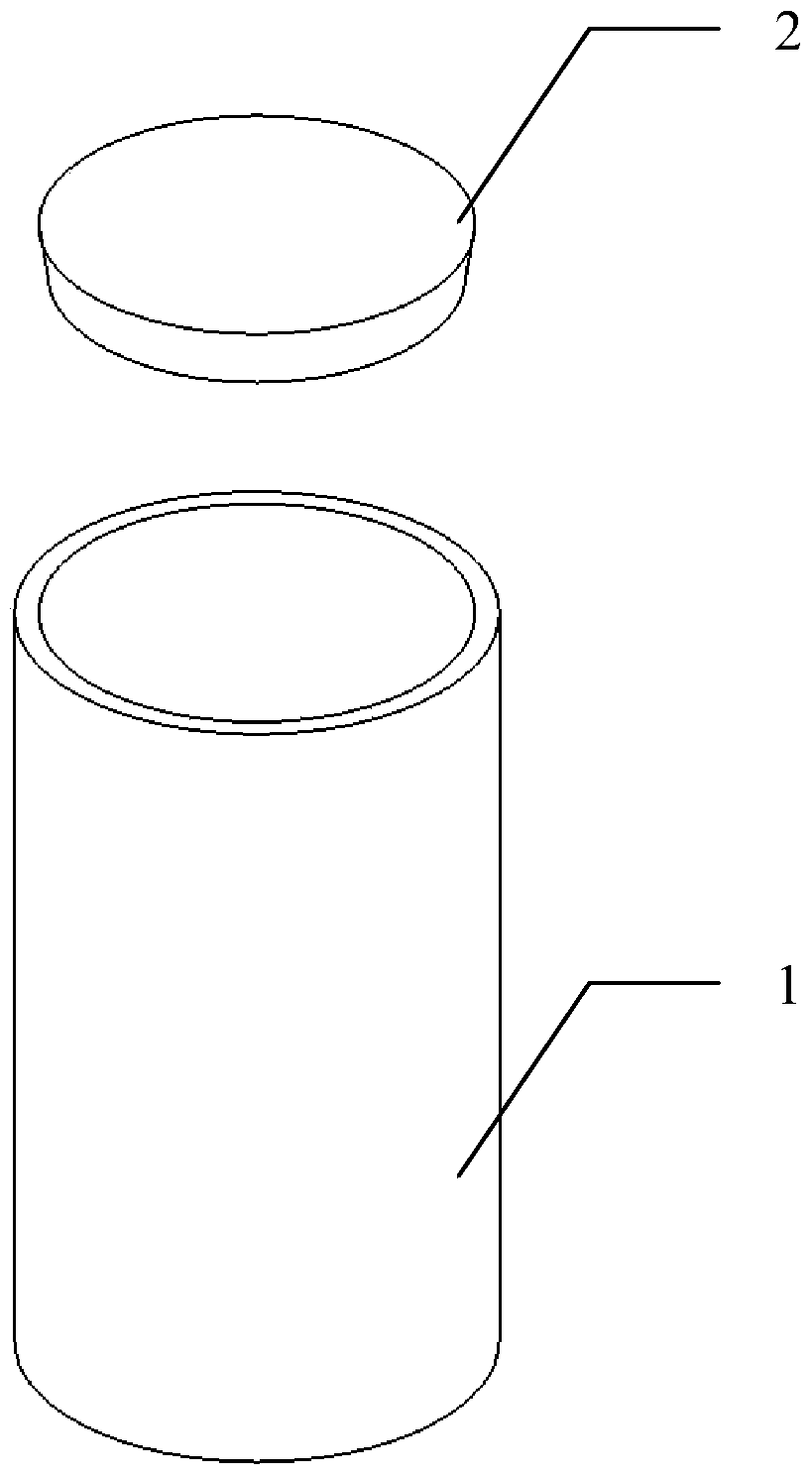

Image

Examples

Embodiment

[0029] Table 1 shows Examples and Comparative Examples according to the present invention. In Table 1, "recipe ingredient" is the weight of each ingredient put into the crucible according to the recipe. "Comparative example" is the NdFeB alloy obtained after smelting by the conventional method, and the weight percentage of each component obtained by component analysis. "Example" is the NdFeB alloy prepared by the method of the present invention, and the weight percentage of each component obtained by component analysis. Among them, in Examples, metals Tb and Ga were placed in a container made of Al. Therefore, the loss of Tb was only 0.02, whereas the loss of Tb in the comparative example was 0.27. Therefore, the loss of Tb is greatly reduced. Ga basically has no loss.

[0030] Table 1

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com