A kind of coating composition and its preparation method and coating and the method for protecting permanent magnetic material

A composition and coating technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of large attenuation of magnetic properties of permanent magnet materials, poor resistance to salt spray, high baking and curing temperature, and achieve protection against Rust corrosion, stable and durable magnetic properties, excellent salt spray resistance and high temperature steam water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

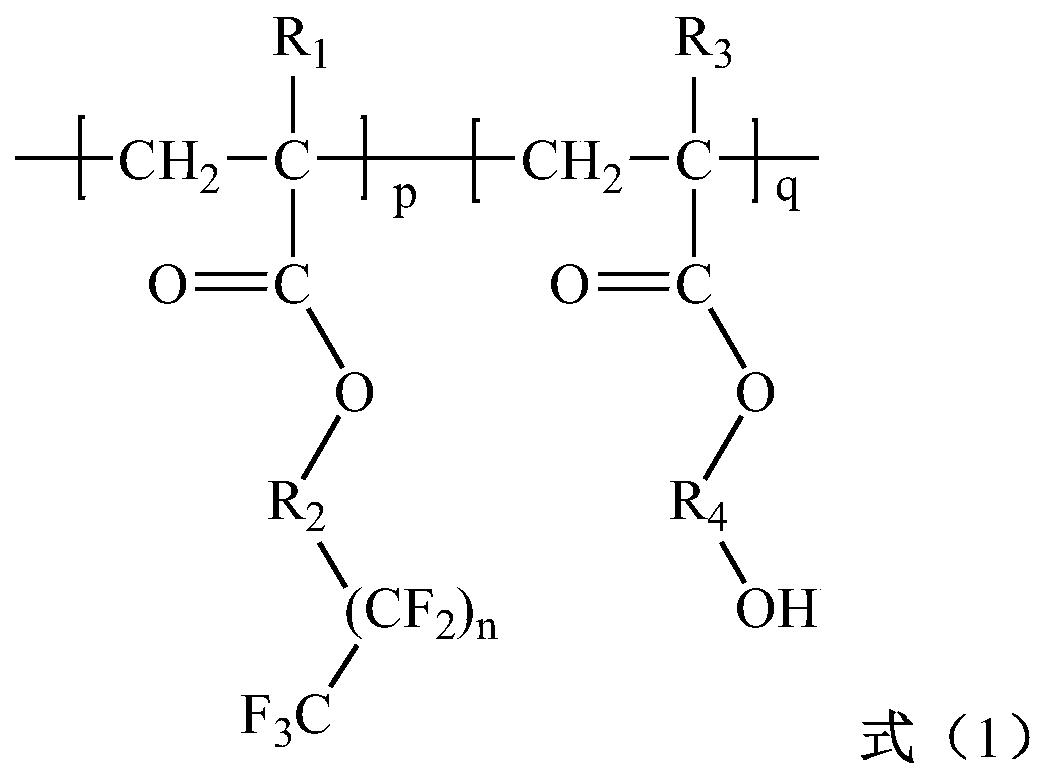

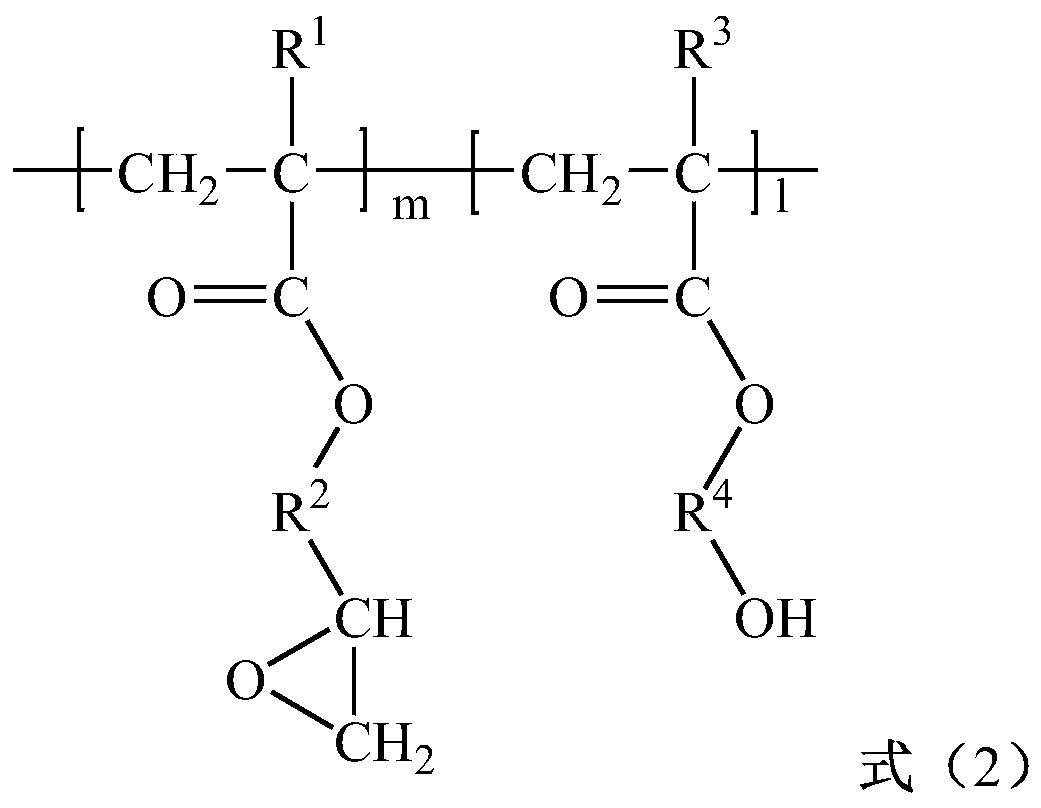

[0015] The fluorine-modified hydroxyacrylic resin may be various existing hydroxyacrylic resins modified with fluorine-containing groups. According to a preferred embodiment of the present invention, the fluorine-modified hydroxyacrylic resin has a structure shown in formula (1):

[0016]

[0017] Among them, R 1 and R 3 each independently H or C 1 -C 5 straight-chain or branched-chain alkyl, R 2 and R 4 each independently is absent or C 1 -C 5 Linear or branched alkylene, n is an integer of 1-4, p is an integer of 300-500, and q is an integer of 300-500; preferably, R 1 and R 3 each independently H or C 1 -C 3 straight chain alkyl, R 2 and R 4 each independently is absent or C 1 -C 3 straight-chain alkylene, n is an integer of 2-3, p is an integer of 350-450, and q is an integer of 350-450. In addition, the number average molecular weight of the fluorine-modified hydroxyacrylic resin is preferably 20000-40000, more preferably 22000-38000, most preferably 250...

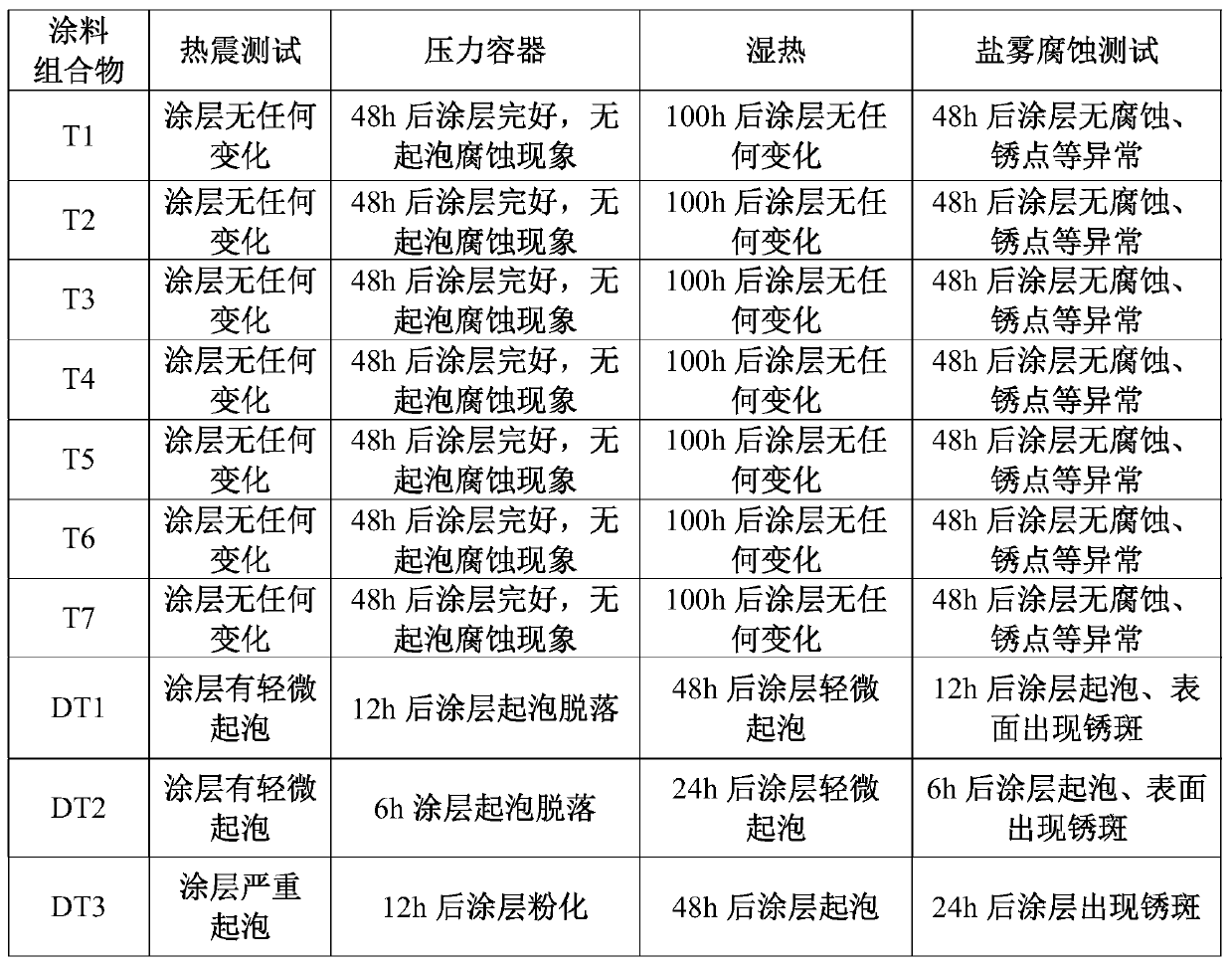

Embodiment 1

[0054] This example is used to illustrate the coating composition provided by the present invention and its preparation method.

[0055] The composition and weight percent of the coating composition described in the present embodiment are as follows:

[0056] Fluorine-modified hydroxyacrylic resin (Daikin GK570), 33% by weight; Epoxy-modified hydroxyacrylic resin (A102), 5% by weight; Blocked isocyanate (Bayer BL-3175), 22% by weight; Catalyst (organotin, T -12), 0.3% by weight; Silica (Grace C803, D90 is 6 μm), 4% by weight; Phosphate ester (Lubrizol 2063), 3% by weight; Butyl acetate, 30% by weight; Gusa 6#), 1.5% by weight; dispersant (BYK-163), 1.2% by weight.

[0057] The preparation process is as follows: Add half-butyl acetate, carbon black, epoxy-modified hydroxyacrylic resin and dispersant into the container and stir evenly, then use a grinder to grind into a color paste with a fineness of less than 15 μm, and then pour it into the color paste in turn Add fluorine-m...

Embodiment 2

[0059] This example is used to illustrate the coating composition provided by the present invention and its preparation method.

[0060] The composition and weight percent of the coating composition described in the present embodiment are as follows:

[0061] Fluorine-modified hydroxyacrylic resin (GK-580), 30% by weight; Epoxy-modified hydroxyacrylic resin (E-58), 8% by weight; Blocked isocyanate (BLR-8086), 22% by weight; Catalyst (organotin, T-12), 0.3% by weight; Silicon dioxide (Grace C803, D90 is 6 μm), 4% by weight; Phosphate ester (Changxing YX-909), 3% by weight; Butyl acetate, 30% by weight; Carbon black ( Degussa 6#), 1.5% by weight; Dispersant (BYK-163), 1.2% by weight.

[0062] The preparation process is as follows: add half of butyl acetate, carbon black, epoxy-modified hydroxyacrylic resin and dispersant into the container and stir evenly, then grind it into a color paste with a fineness of less than 15 μm, and then add fluorine to the color paste in sequence ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com