A method for improving the magnetic properties of sintered NdFeB magnets

A neodymium iron boron, magnetic performance technology, used in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of easy reaction and heat generation, affecting magnetic performance, instability, etc., to improve the diffusion depth and improve the diffusion effect. , the effect of improving the coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

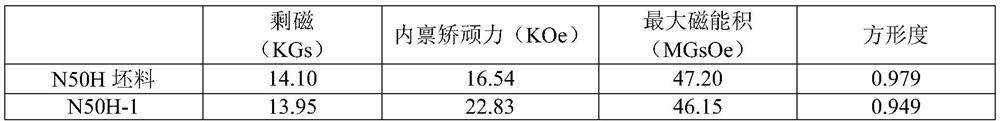

Embodiment 1

[0032] A method for improving the magnetic properties of sintered NdFeB magnets, comprising the following steps:

[0033] (1) DyAl alloy powder with an average particle size of 2.5 μm is obtained by mixing Dy and Al with a mass percentage of 80% and 20% through rapid solidification, hydrogen crushing and jet milling;

[0034] (2) After smelting, powder making, molding, and sintering processes, the N50H blank is obtained, and a sintered NdFeB magnet with a specification of 30*25*3mm is obtained through machining, and the surface of the magnet is pretreated by degreasing and descaling;

[0035] (3) DyAl alloy powder is dispersed in absolute ethanol to form a suspension to obtain a diffusion coating. Polyisobutylene and cyclohexylamine nitrite are mixed at a mass ratio of 95:5, and solvent absolute ethanol is added to obtain an organic layer coating. ;

[0036] (4) Evenly coat the diffusion coating on the surface of the NdFeB magnet to form a 100μm RM coating, and then immediately...

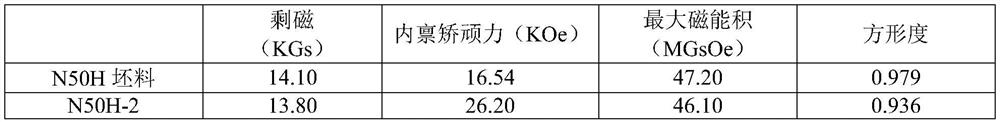

Embodiment 2

[0043] A method for improving the magnetic properties of sintered NdFeB magnets, comprising the following steps:

[0044] (1) Tb and Fe that are 90% and 10% by mass percentage are mixed, and the TbFe alloy powder with an average particle size of 2.3 μm is obtained through rapid solidification, hydrogen crushing and jet milling;

[0045] (2) After smelting, powder making, molding, and sintering processes, the N50H blank is obtained, and a sintered NdFeB magnet with a specification of 30*25*3mm is obtained through machining, and the surface of the magnet is pretreated by degreasing and descaling;

[0046] (3) TbFe alloy powder is dispersed in absolute ethanol to form a suspension to obtain a diffusion coating. Mix phenolic resin and benzotriazole in a mass percentage of 95:5, add solvent absolute ethanol to obtain an organic layer coating ;

[0047] (4) Apply the diffusion paint evenly on the surface of the NdFeB magnet to form a 120 μm RM coating, and then immediately spray th...

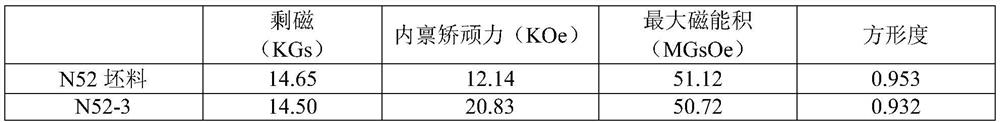

Embodiment 3

[0054] A method for improving the magnetic properties of sintered NdFeB magnets, comprising the following steps:

[0055] (1) Dy, Tb, and Co are mixed with mass percentages of 30%, 65%, and 5%, and the DyTbCo alloy powder with an average particle size of 2.3 μm is obtained through rapid solidification, hydrogen crushing, and jet milling;

[0056] (2) After smelting, powder making, molding, and sintering processes, N52 blanks are obtained, and a sintered NdFeB magnet with a specification of 49*21*2mm is obtained through machining, and the surface of the magnet is degreased and descaled for pretreatment;

[0057] (3) DyTbCo alloy powder is dispersed in absolute ethanol to form a suspension to obtain a diffusion coating. Mix silicone rubber and benzotriazole at a mass ratio of 97:3, add solvent absolute ethanol to obtain an organic layer coating;

[0058] (4) Apply the diffusion paint evenly on the surface of the NdFeB magnet to form a 100 μm RM coating, and then immediately spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com