Nano biphase isotropic composite permanent magnet and preparation method thereof

An isotropic, permanent magnet technology, used in the manufacture of magnetic objects, permanent magnets, inductors/transformers/magnets, etc., can solve problems such as difficult application and increased cost, and achieve high remanence, improved magnet performance, and high magnetic energy product. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

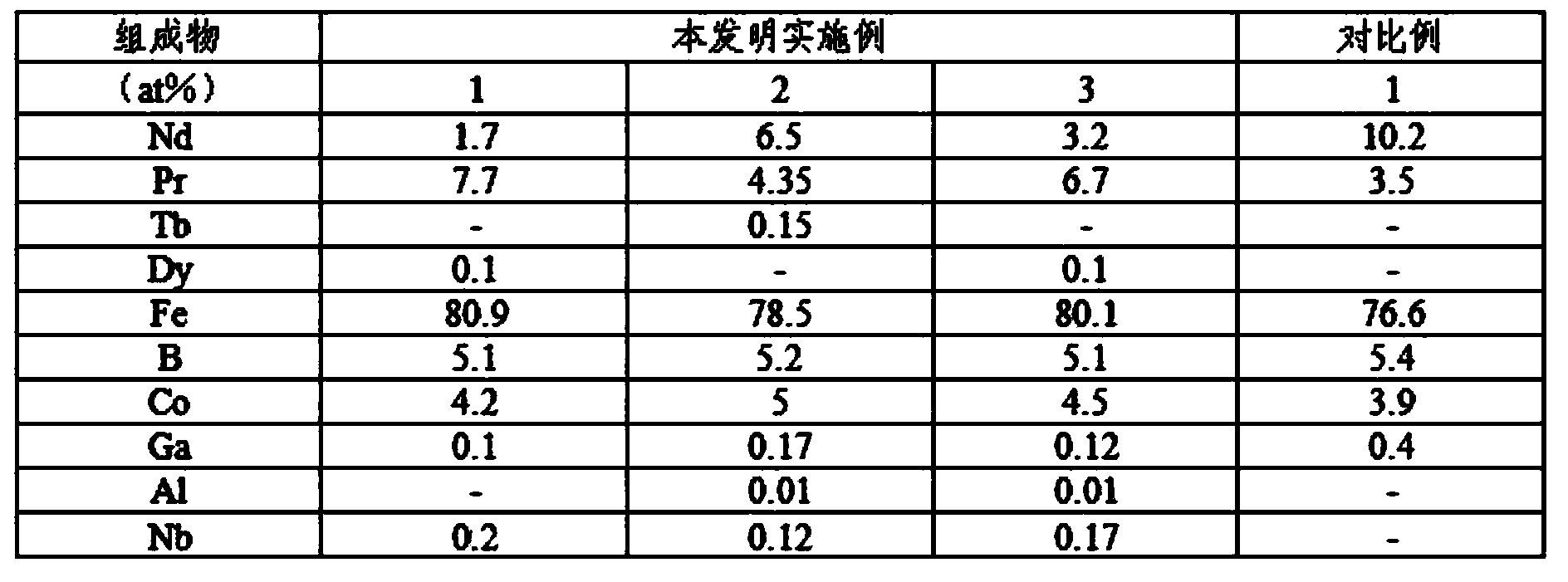

Embodiment 1

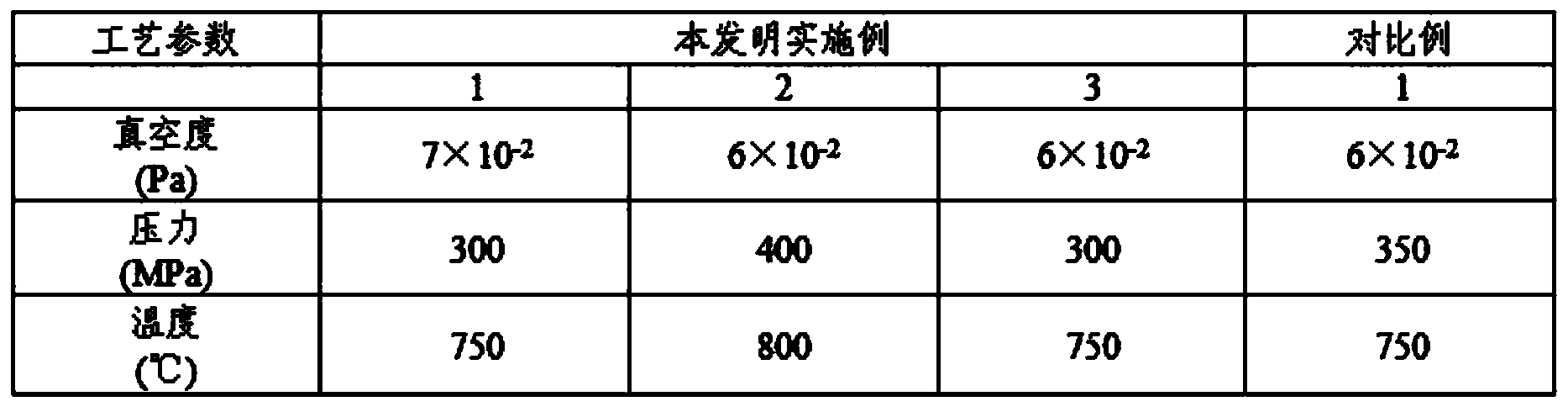

[0027] (1) Change the composition to Nd 1.7 PR 7.7 Dy 0.1 Fe 80.9 B 5.1 co 4.2 Ga 0.1 Nb 0.2 Nano dual-phase quenching alloy powder is pressed into Φ at 25°C and 400MPa pressure 外 45mm×Φ 内 39mm×50mm high ring blank;

[0028] (2) Coat the surface of the ring blank with boron nitride / absolute ethanol mixed lubricant and dry;

[0029] (3) Place the ring blank at 750°C, 7×10 -2 Under the condition of Pa vacuum, the pressure of 300MPa is used to press, and the size is Φ 外 46mm×Φ 内 38mm x 32mm high full-density isotropic composite permanent magnet;

[0030] (4) After the surface of the pressed ring blank is ground, the sample is cut out by a wire electric discharge machine for testing.

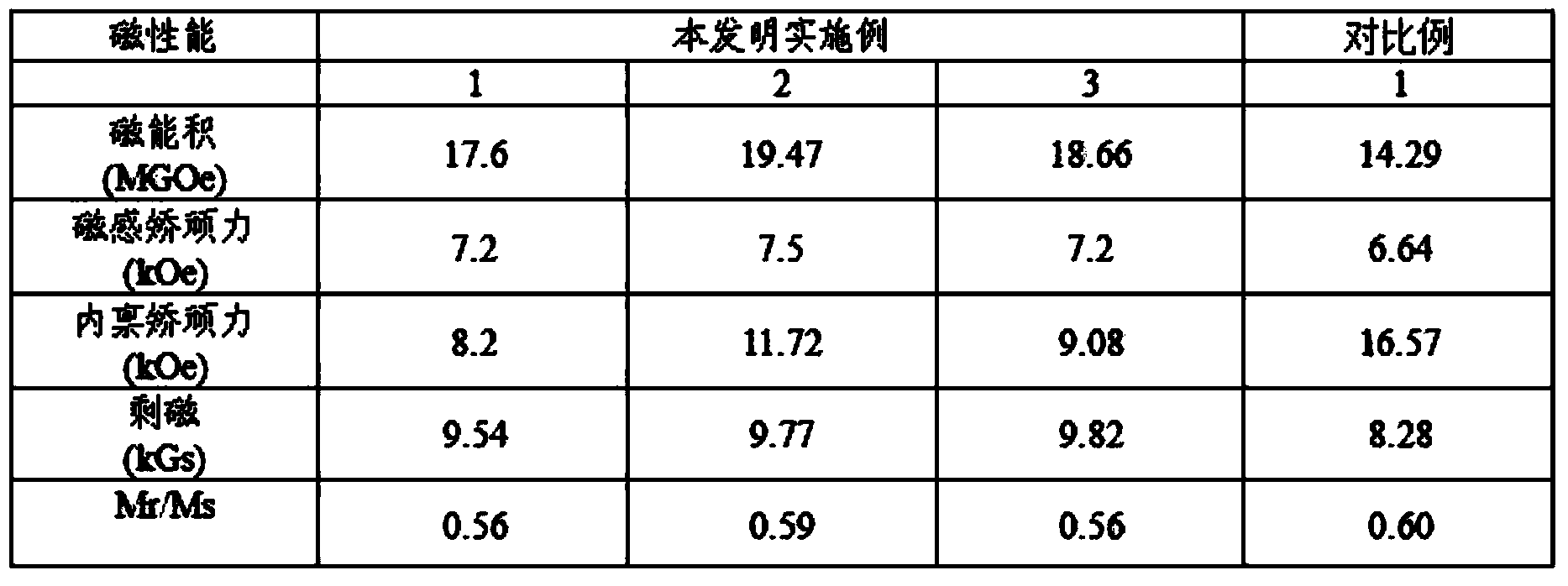

[0031] Magnetic test results with a hysteresis loop: Br=9.54kGs, bHc=7.2kOe, iHc=8.2kOe, (BH) max =17.6MGOe, the recoil permeability is 1.2, and finally the 6-pole magnetization is carried out, and the magnetic flux intensity on the surface of the magnetic poles is measured as 2.9kGs b...

Embodiment 2

[0033] (1) Divide the composition into Nd 6.5 PR 4.35 Tb 0.15 Fe 78.5 B 5.2 co 5 Ga 0.17 Al 0.01 Nb 0.12Nano dual-phase quenching alloy powder is pressed into Φ at 20°C under a pressure of 500MPa 外 45mm×Φ 内 39mm×50mm high ring blank;

[0034] (2) Coat the surface of the ring blank with boron nitride / acetone mixed lubricant and dry;

[0035] (3) Place the ring blank at 800°C, 6×10 -2 Under the condition of MPa vacuum, the pressure of 400MPa is used to press, and the size is Φ 外 46mm×Φ 内 38mm x 32mm high full-density isotropic composite permanent magnet;

[0036] (4) After the surface of the pressed ring blank is ground, the sample is cut out by a wire electric discharge machine for testing.

[0037] Magnetic test results measured with a hysteresis loop: Br=9.77kGs, bHc=7.5kOe, iHc=11.72kOe, (BH) max =19.47MGOe, the recoil permeability is 1.15, and finally the 6-pole magnetization is carried out, and the magnetic flux intensity on the surface of the magnetic pole ...

Embodiment 3

[0039] (1) Divide the composition into Nd 3.2 PR 6.7 Dy 0.1 Fe 80.1 B 5.1 co 4.5 Ga 0.12 Al 0.01 Nb 0.17 The nano-dual-phase quenching alloy powder is pressed into Φ at 25°C and a pressure of 500MPa 外 45mm×Φ 内 39mm×50mm high ring blank;

[0040] (2) Apply molybdenum disulfide / acetone mixed lubricant on the surface of the ring blank and dry;

[0041] (3) Place the ring blank at 750°C, 6×10 -2 Under the condition of MPa vacuum, the pressure of 300MPa is pressed, and the relative density is 100%, and the size is Φ 外 46mm×Φ 内 38mm×32mm high isotropic composite permanent magnet;

[0042] (4) After the surface of the pressed ring blank is ground, the sample is cut out by a wire electric discharge machine for testing.

[0043] Magnetic test results with a hysteresis loop: Br=9.82kGs, bHc=7.2kOe, iHc=9.08kOe, (BH) max =18.66MGOe, the recoil permeability is 1.2, and finally the 8-pole magnetization is carried out, and the magnetic flux intensity on the surface of the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com