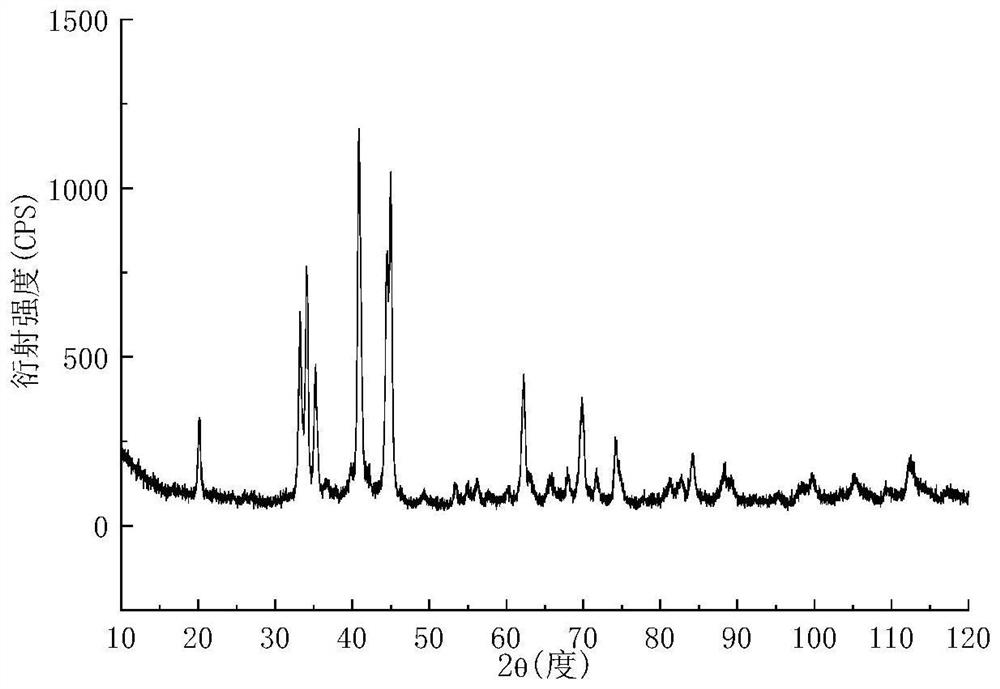

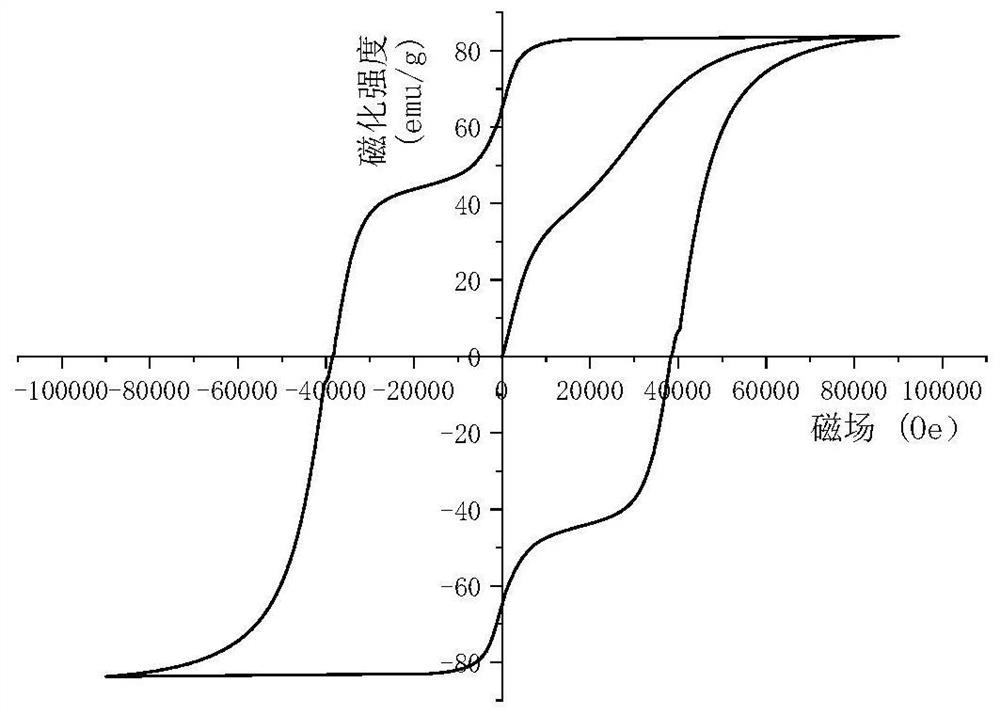

Iron-nickel co-doped SmCo4B-based permanent magnet ribbon and preparation method thereof

A co-doping and thin strip technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve problems that have not yet appeared, and achieve the effect of improving coercive force and magnetization, and good comprehensive magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] SmCo 4 SmCo of B-based permanent magnetic strip 3.5 Fe 0.38 Ni 0.12 Method for the preparation of B thin strips.

[0060] The first step, raw material preparation:

[0061] Calculate the elemental composition formula SmCo according to the atomic ratio (that is, the molar ratio between elements) 3.5 Fe 0.38 Ni 0.12 The mass percentage of the constituent elements in B, according to the mass percentage, weigh the required amount of component raw materials: pure Sm, pure Co, pure Fe, pure Ni and B-Co alloy. 3% pure Sm than the calculated mass percentage of pure Sm, thereby completing the preparation of raw materials;

[0062] The second step is to melt the raw material to prepare the master alloy ingot:

[0063] Put the raw materials prepared in the first step into the crucible of the vacuum arc melting furnace at the same time, and vacuum the furnace body to 3×10 during melting. -3 Pa, the furnace temperature is raised to 50°C higher than the melting point of pure...

Embodiment 2

[0072] SmCo 4 SmCo of B-based permanent magnetic strip 3.0 Fe 0.8 Ni 0.2 Method for the preparation of B thin strips.

[0073] The first step, raw material preparation:

[0074] Calculate the elemental composition formula SmCo according to the atomic ratio 3.0 Fe 0.8 Ni 0.2 The mass percentage of the constituent elements in B, according to the mass percentage, weigh the required amount of component raw materials: pure Sm, pure Co, pure Fe, pure Ni and pure B powder, and additionally add according to the above-mentioned raw material ratio during batching. Weigh pure Sm with a mass percentage of 5% of pure Sm, thereby completing the preparation of raw materials;

[0075] The second step is to melt the raw material to prepare the master alloy ingot:

[0076] Put the B powder prepared in the first step into the silo separately, and put other raw materials into the crucible of the vacuum induction melting furnace at the same time. During the melting, the furnace body is fir...

Embodiment 3

[0084] SmCo 4 SmCo of B-based permanent magnetic strip 2.2 Fe 1.2 Ni 0.6 Method for the preparation of B thin strips.

[0085] The first step, raw material preparation:

[0086] Calculate the elemental composition formula SmCo according to the atomic ratio 2.2 Fe 1.2 Ni 0.6 The mass percentage of the constituent elements in B, according to the mass percentage, weigh the required amount of component raw materials: pure Sm, pure Co, pure Fe, pure Ni and B-Co alloy, and additionally add the above-mentioned raw materials when batching. The pure Sm with a mass percentage of 6% of pure Sm is taken, thereby completing the preparation of raw materials;

[0087] The second step is to melt the raw material to prepare the master alloy ingot:

[0088] Put the raw materials prepared in the first step into the crucible of the vacuum induction melting furnace at the same time, and vacuum the furnace body to 4×10 before melting. -2 Pa, the furnace temperature rises to 180°C higher th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Intrinsic coercive force | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com