SiO2 antireflection thin film and preparation method thereof

An anti-reflection and thin-film technology, applied in the field of SiO2 anti-reflection thin film and its preparation, can solve the problems that the thin film cannot be used for a long time, easily absorb water, dust, and hollow particles with large particle size, and achieves low preparation cost and increased wiping resistance. , Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] According to TEOS, deionized water in ammonia water, ammonia in ammonia water (NH 3 ), the mol ratio of absolute ethanol and PAA is 1: 67: 28: 530: 0.015 configuration raw material;

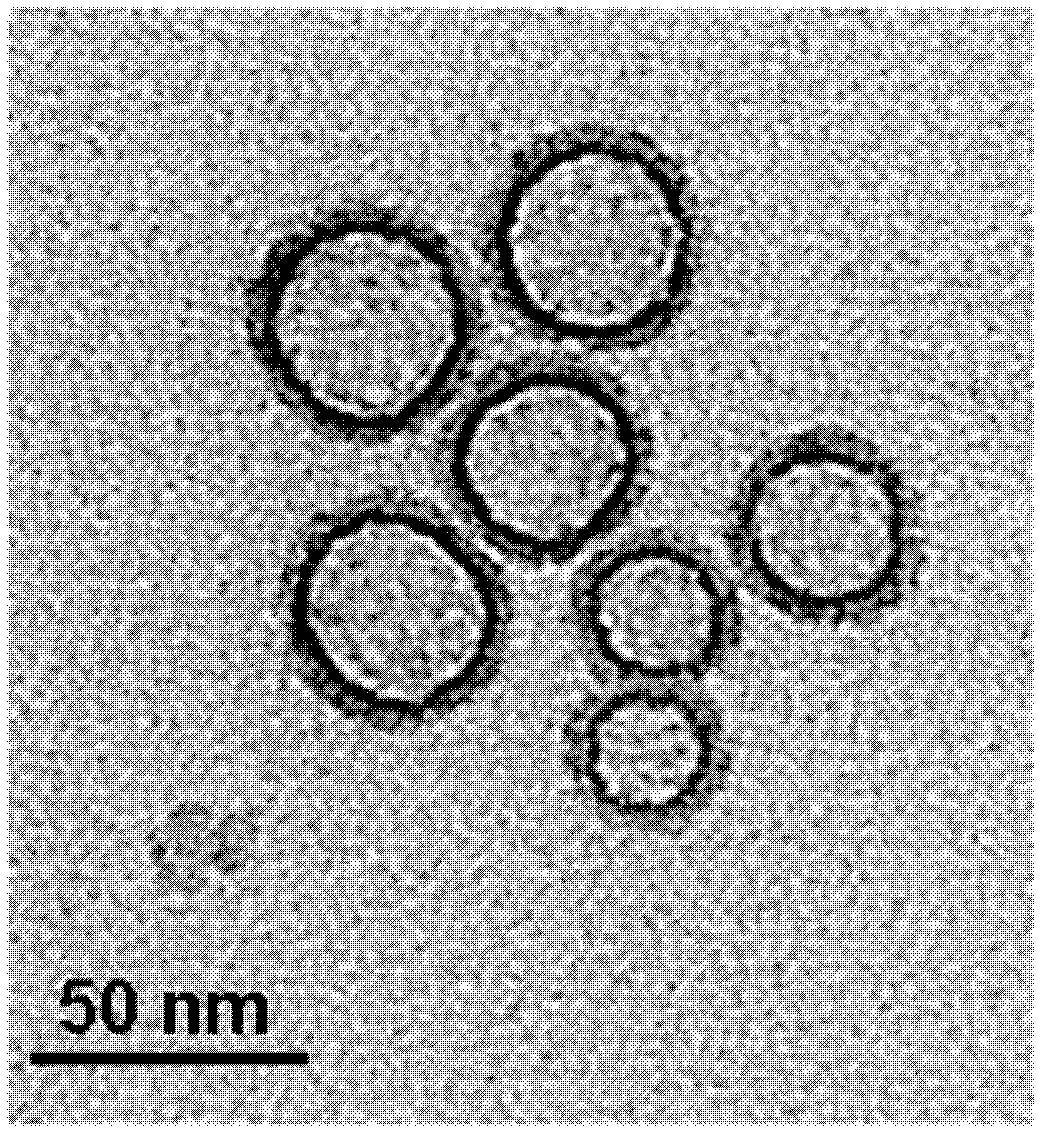

[0042]Disperse PAA (average molecular weight 3000) in ammonia water, stir evenly, add to absolute ethanol, stir evenly in a magnetic stirrer, then add TEOS in 5 times in equal amounts, with an interval of 1 hour between each time. After adding all TEOS, continue to stir for 10h to obtain light blue SiO 2 Nano hollow particle sol (ie dispersion). The SiO 2 The TEM image of the hollow particle sol is as follows figure 1 , SiO 2 The shape of hollow particles is regular, the wall thickness is uniform, the size distribution range is small, SiO 2 The particle size of the hollow particle is 30nm-45nm, the wall thickness is 5nm, and the relative standard deviation of the particle size is 6%.

[0043] Acid-catalyzed SiO 2 The sol is obtained by hydrolysis of TEOS, with hydrochloric acid (HCl...

Embodiment 2

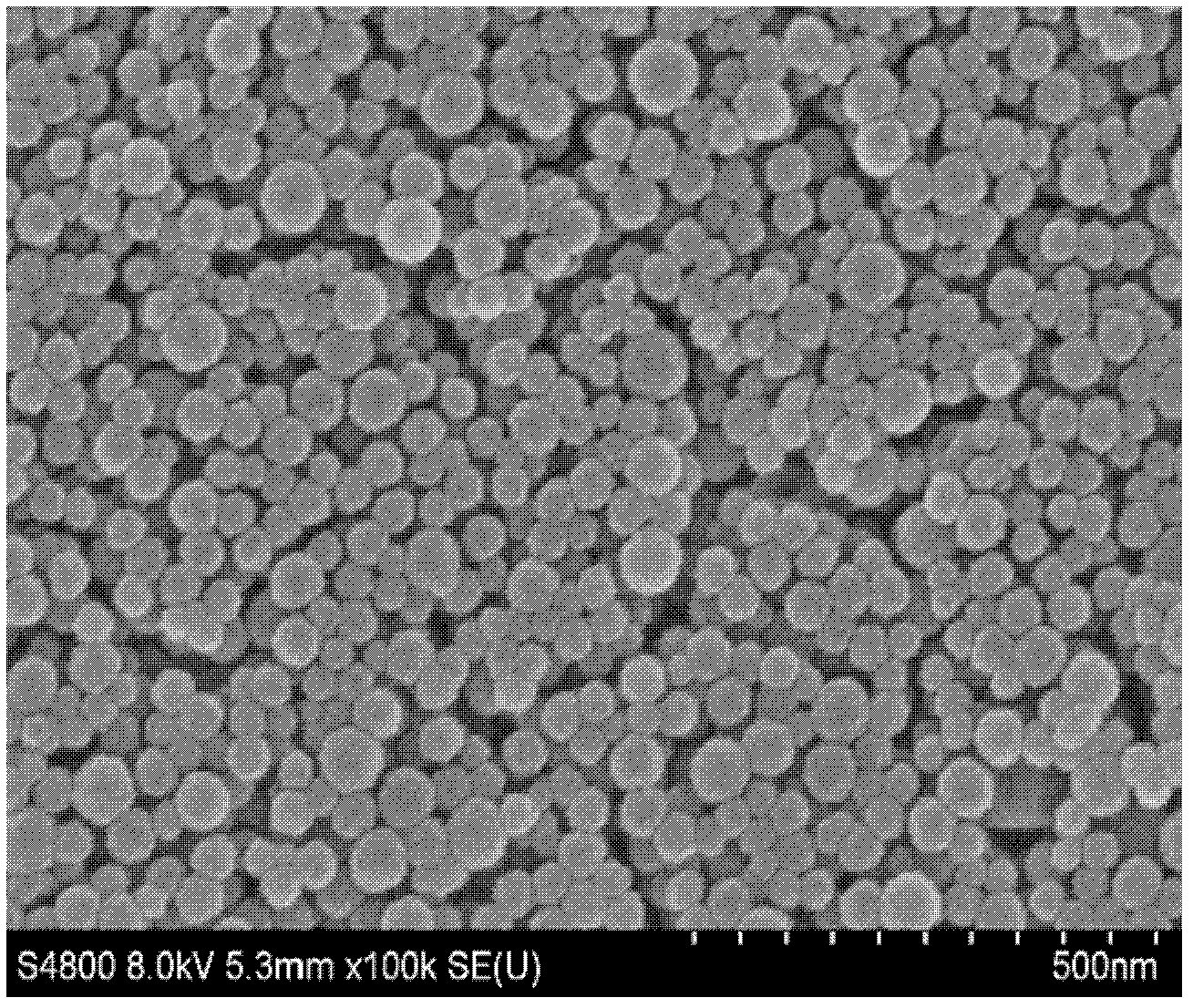

[0051] According to TEOS, deionized water in ammonia water, ammonia in ammonia water (NH 3 ), the mol ratio of absolute ethanol and PAA is 1: 48: 20: 375: 0.014 configuration raw material;

[0052] Disperse PAA (average molecular weight 3000) in ammonia water, stir evenly, add to absolute ethanol, stir evenly in a magnetic stirrer, then add TEOS in 5 times in equal amounts, with an interval of 1 hour between each time. After adding all TEOS, continue to stir for 10h to obtain blue-white SiO 2 Hollow particle sol. The SiO 2 SiO in hollow particle sol 2 Hollow particles have regular shape and uniform wall thickness, SiO 2 The particle size of the hollow particle is 60nm-120nm, the wall thickness is 5nm, and the relative standard deviation of the particle size is 21%.

[0053] All the other operations are the same as in Example 1, preparing SiO 2 Anti-reflection film, the related properties of the film are shown in Table 1.

Embodiment 3

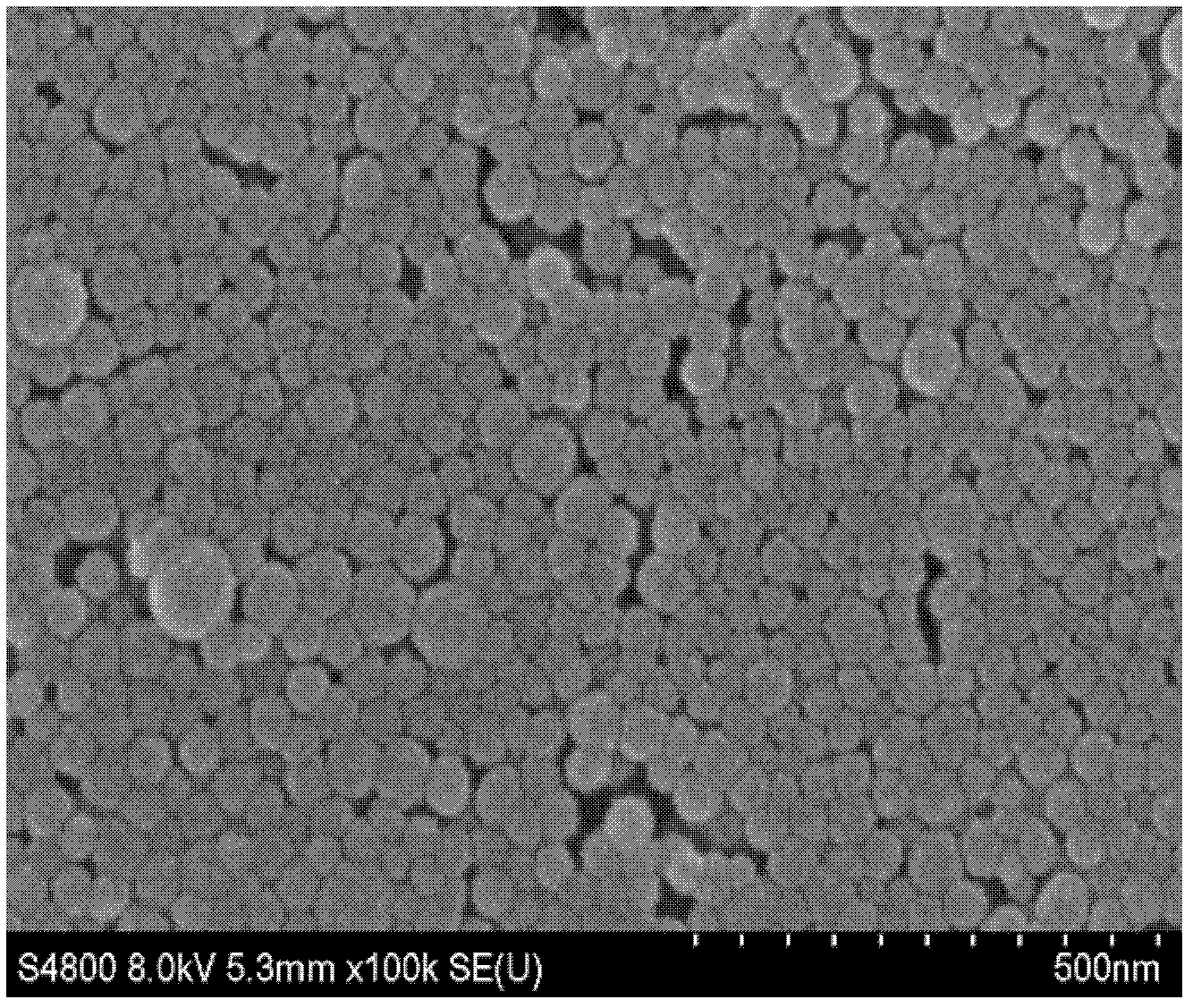

[0055] According to TEOS, deionized water in ammonia water, ammonia in ammonia water (NH 3 ), the mol ratio of absolute ethanol and PAA is 1: 90: 37: 700: 0.02 configuration raw material;

[0056] Disperse PAA (average molecular weight 3000) in ammonia water, stir evenly, add to absolute ethanol, stir evenly in a magnetic stirrer, then add TEOS in 5 times in equal amounts, with an interval of 1 hour between each time. After adding all TEOS, continue to stir for 10h to obtain light blue SiO 2 Hollow particle sol. The SiO 2 SiO in hollow particle sol 2 Hollow particles have regular shape and uniform wall thickness, SiO 2 The particle size of the hollow particle is 30nm-45nm, the wall thickness is 3nm, the relative standard deviation of the particle size is 12%, and there are broken particles.

[0057] All the other operations are the same as in Example 1, preparing SiO 2 Anti-reflection film, the related properties of the film are shown in Table 1.

[0058] Under the obse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com