Coating, coated articles and methods of manufacture thereof

A coating and coating technology, applied in the fields of coating, prosthesis, medical science, etc., can solve the problems of apatite-implant interface damage, etc., and achieve the effect of good viscosity and good biological reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

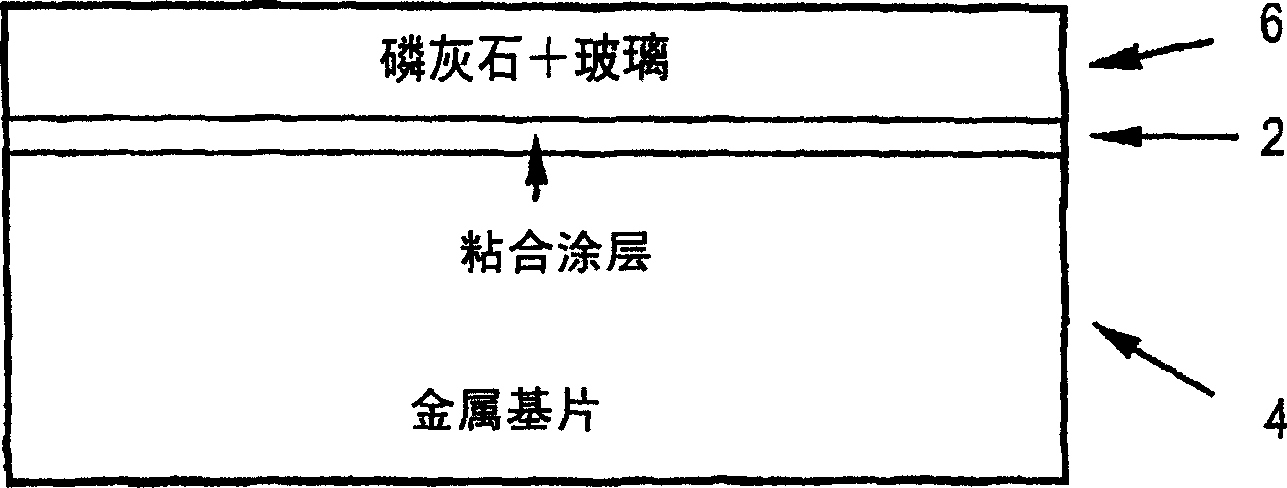

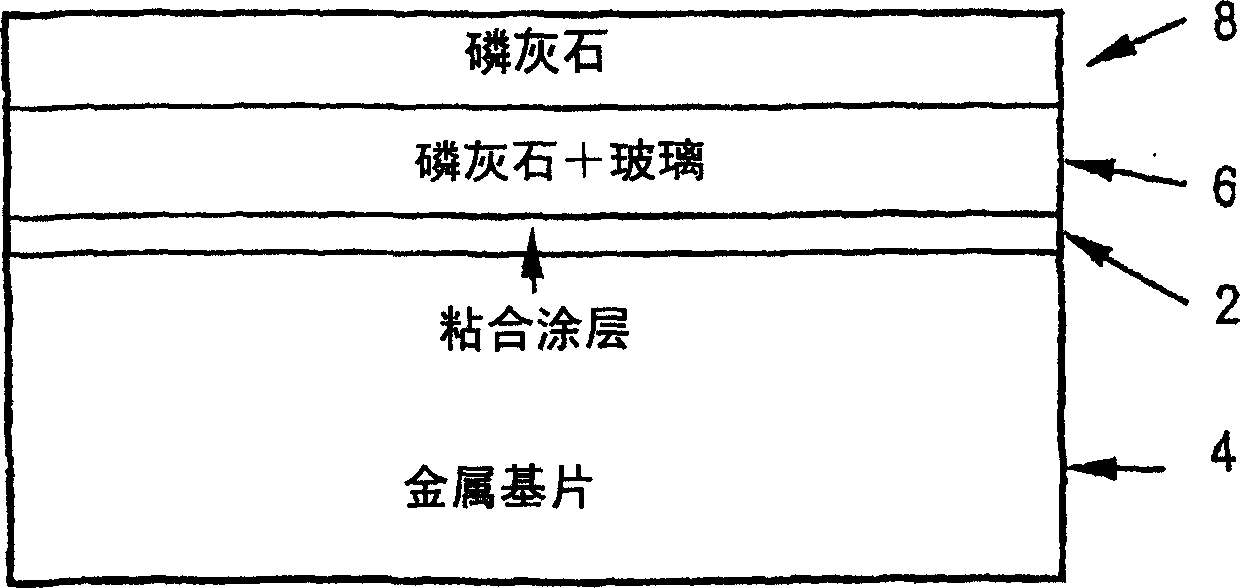

[0093] The substrate was Ti6Al4V available from Prudential Titanium Inc., MA. The metal substrate measures 1.0 inches in diameter by 0.125 inches in thickness and is grit blasted. The samples were coated with a TiN first layer using a PVD process at Ionbond Inc., NJ. The thickness of the first layer is about 4 microns.

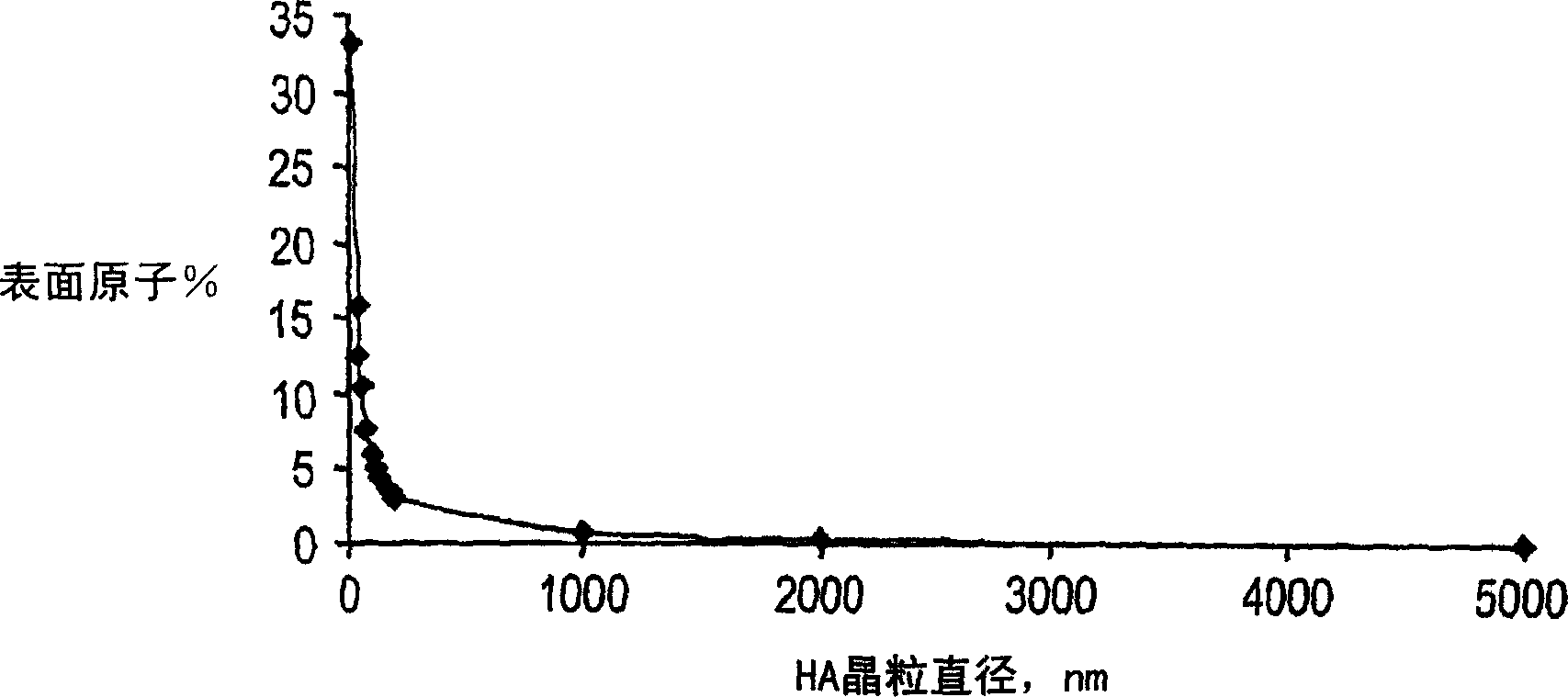

[0094] The second layer contains stabilized silicate glass and nanoscale hydroxyapatite powder. The composition of the silicate glass is 67.8% SiO by weight 2 , 10.30 wt% B 2 o 3 , 8.30 wt% Na 2 O, 5.20 wt% Al 2 o 3 , 4.20 wt% K 2 O, 2.10 wt% LiO 2 , 1.05 wt% ZrO 2 , and 1.05 wt% TiO 2 . The glass is ground into a powder with a particle size of less than about 1.0 microns. Glass powder is stable in hot water, and its coefficient of thermal expansion is 7.8×10 -6 / °C. Nanoscale hydroxyapatite was synthesized by Inframat Corporation using chemical precipitation and autoclaving. The particle size of hydroxyapatite is about 30-50 nanometers. Hydro...

Embodiment 2

[0098] The substrate was Ti available from Prudential Titanium Inc., MA. The metal substrate measures 1.0 inches in diameter by 0.125 inches in thickness and is grit blasted. The samples were coated with a TiN first layer using a PVD process at Ionbond Inc., NJ. The thickness of the first layer is about 4 microns.

[0099] The second layer contains stabilized silicate glass and nanoscale hydroxyapatite powder. The composition of the silicate glass is 70.80% SiO by weight 2 , 9.30 wt% B 2 o 3 , 8.30 wt% Na 2 O, 5.20 wt% Al 2 o 3 , 2.20 wt% K 2 O, 2.10 wt% LiO 2 , 1.05 wt% ZrO 2 , and 1.05 wt% TiO 2 . The glass is ground into a powder with a particle size of less than about 1.0 microns. Glass powder is stable in hot water, and its coefficient of thermal expansion is 6.6×10 -6 / °C. Nanoscale hydroxyapatite was synthesized by Inframat Corporation using chemical precipitation and autoclaving. The particle size of hydroxyapatite is about 30-50 nanometers. Hydroxyapa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com