Miniature gas chromatographic column, gas chromatographic system and method for analysizing composition in sample

A gas chromatographic system and gas chromatographic column technology, which are applied in the directions of analysis materials, material separation, and measurement devices, and can solve the problems of insufficient length of micro-fabricated gas chromatographic columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

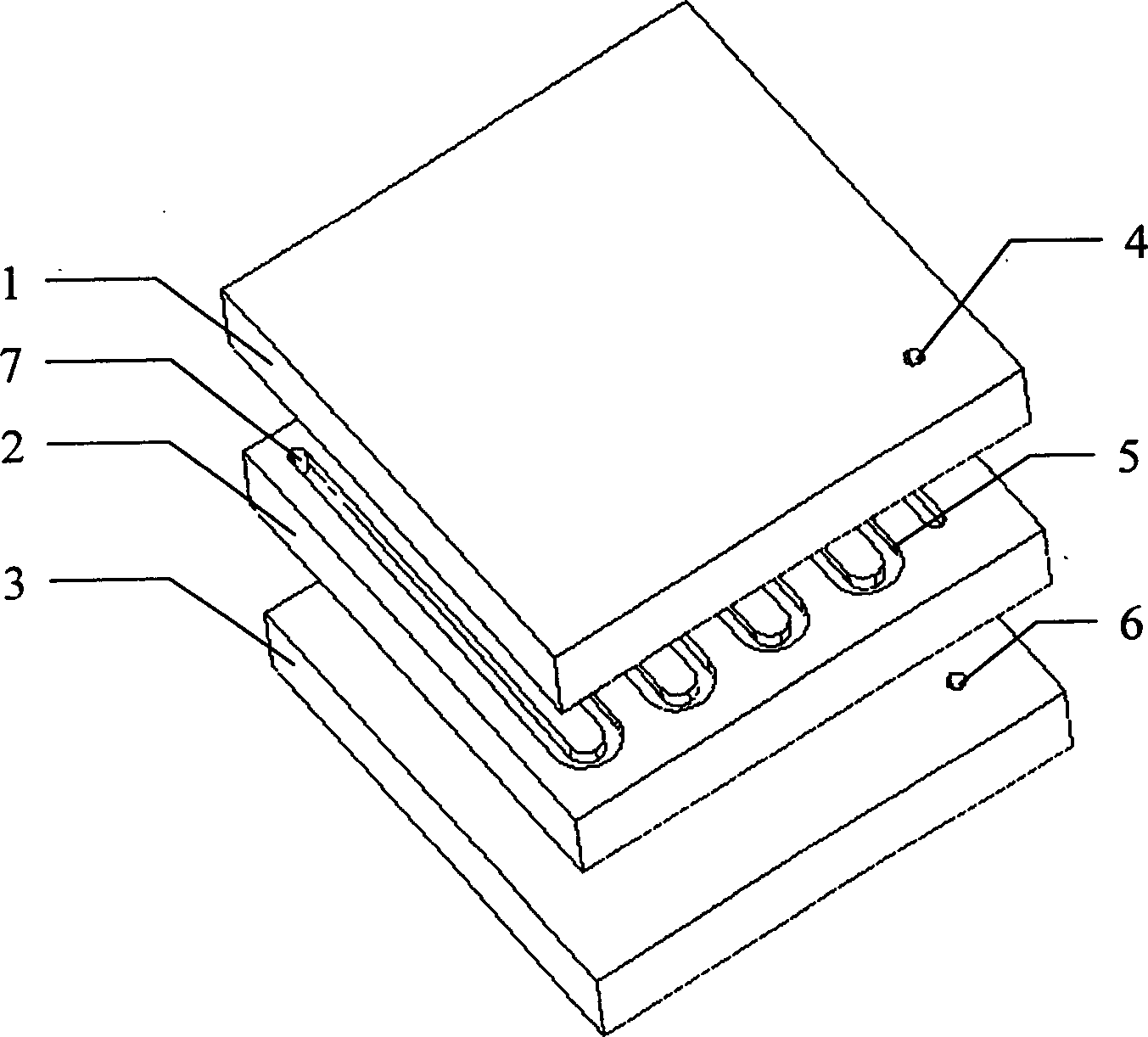

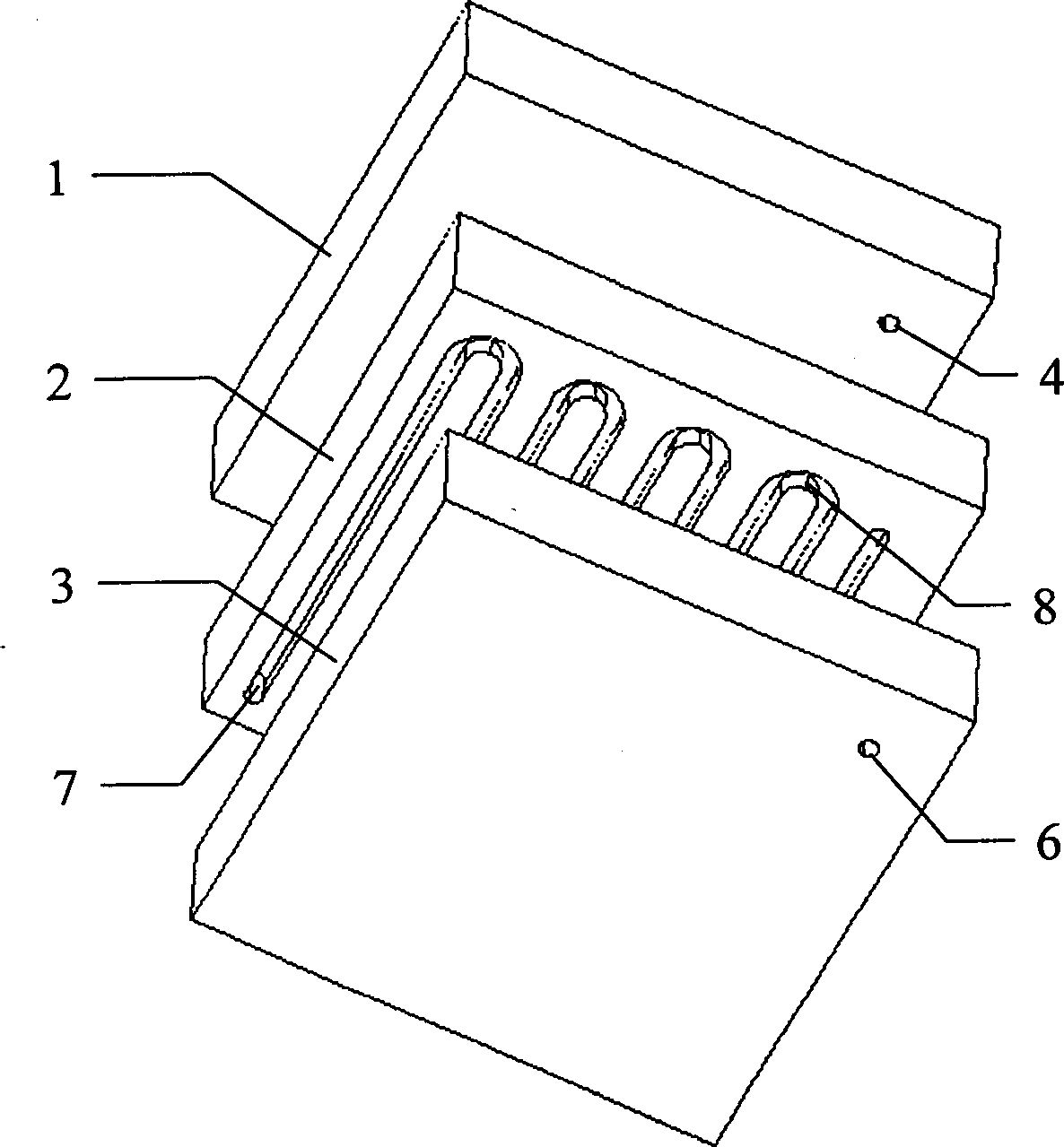

[0044] One objective of this particular embodiment is to obtain a type of micromachined gas chromatography column. Another object of this particular embodiment is to obtain a structure that is more compact than that of previous micro-machined gas chromatography columns.

[0045] In short, the micromachined gas chromatography column of this embodiment is manufactured by combining two or more layers together. The micro gas path is formed by etching on some layers and then covering it with other layers to create a complete capillary. Each layer has at least one function, either forming a groove or covering the groove to form a complete capillary, or both functions. In order to connect the adjacent ends of two capillaries in different layers, a through hole is formed in the layer between the two capillaries. In this way all the capillaries are connected together, creating a full-length capillary. The full-length capillary leads to the outside at both ends through through holes on the ...

Embodiment 1

[0050] In order to coat the capillary wall, traditional static or dynamic methods can be used. The traditional static method uses a stationary phase solution, such as SE-30 solution dissolved in chloroform, to fill the capillary, and then evaporate the solvent, leaving the stationary phase in the form of a deposit. The traditional dynamic method uses gas pressure to push some stationary phases of the solution through the capillary, and some stationary phases remain in the form of deposits. The new method of coating the capillary wall is to deposit a stationary phase on the corresponding areas of the gas path wall and the surface of the cover layer before bonding these layers together. Example 1. Drug testing

[0051] The substance extracted from human urine can be injected into the gas chromatography system as a sample. The components of the urine sample are separated by gas chromatography as described above, then detected by a detector, and reported to the user. If the provider o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com