Forging method of lower sealing head forge piece of one-mega kilowatt nuclear-power reactor pressure vessel

A technology of pressure vessels and reactors, applied in the direction of metal processing equipment, etc., can solve problems such as the lack of mature manufacturing technology and production equipment capabilities, and achieve the effects of reasonable distribution of metal streamlines, uniform composition, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

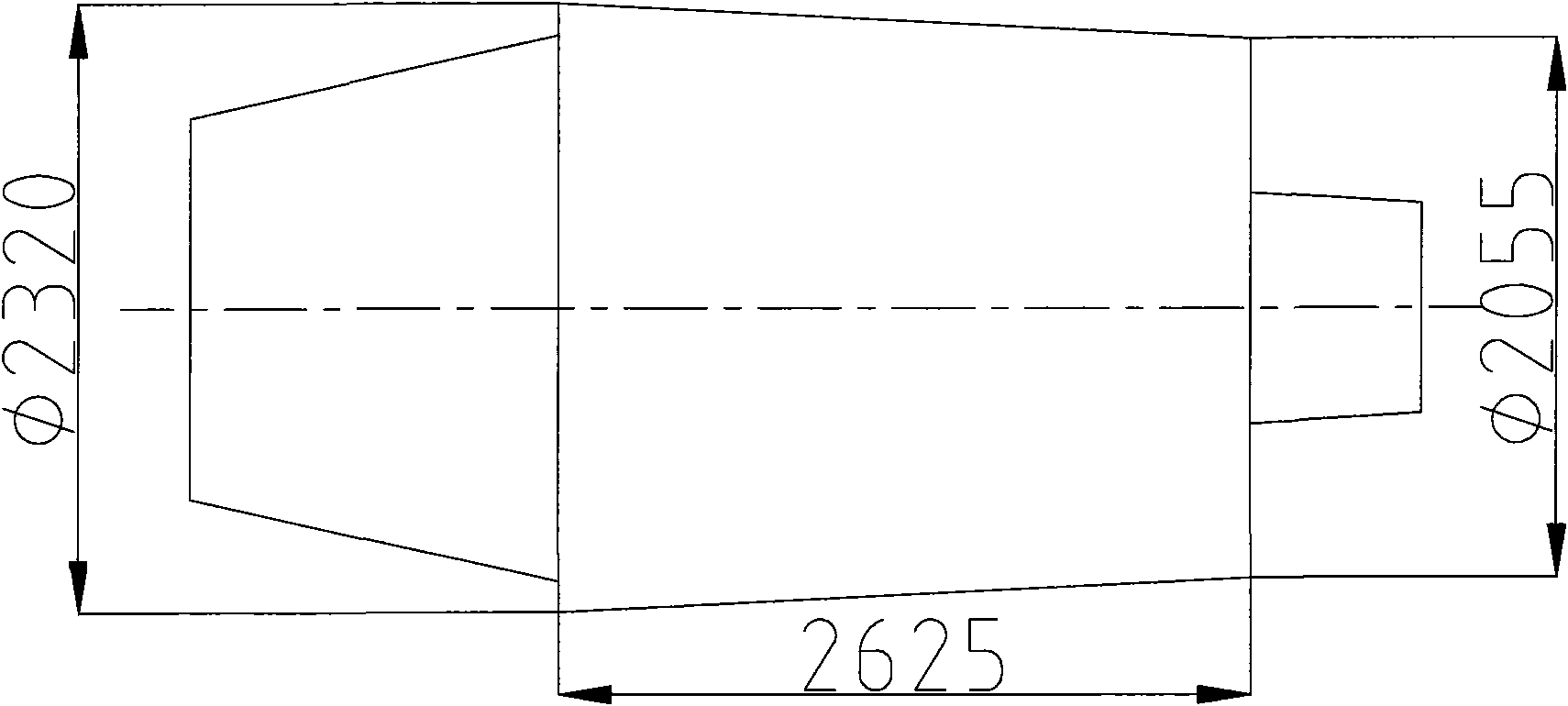

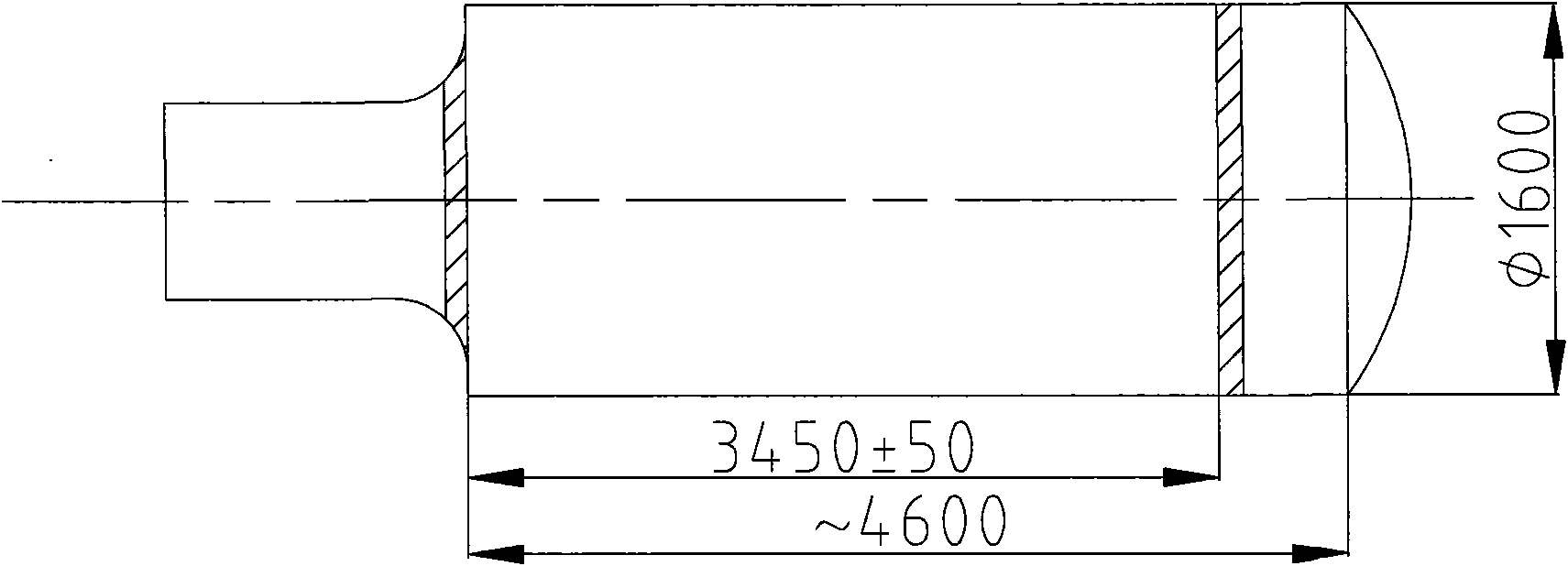

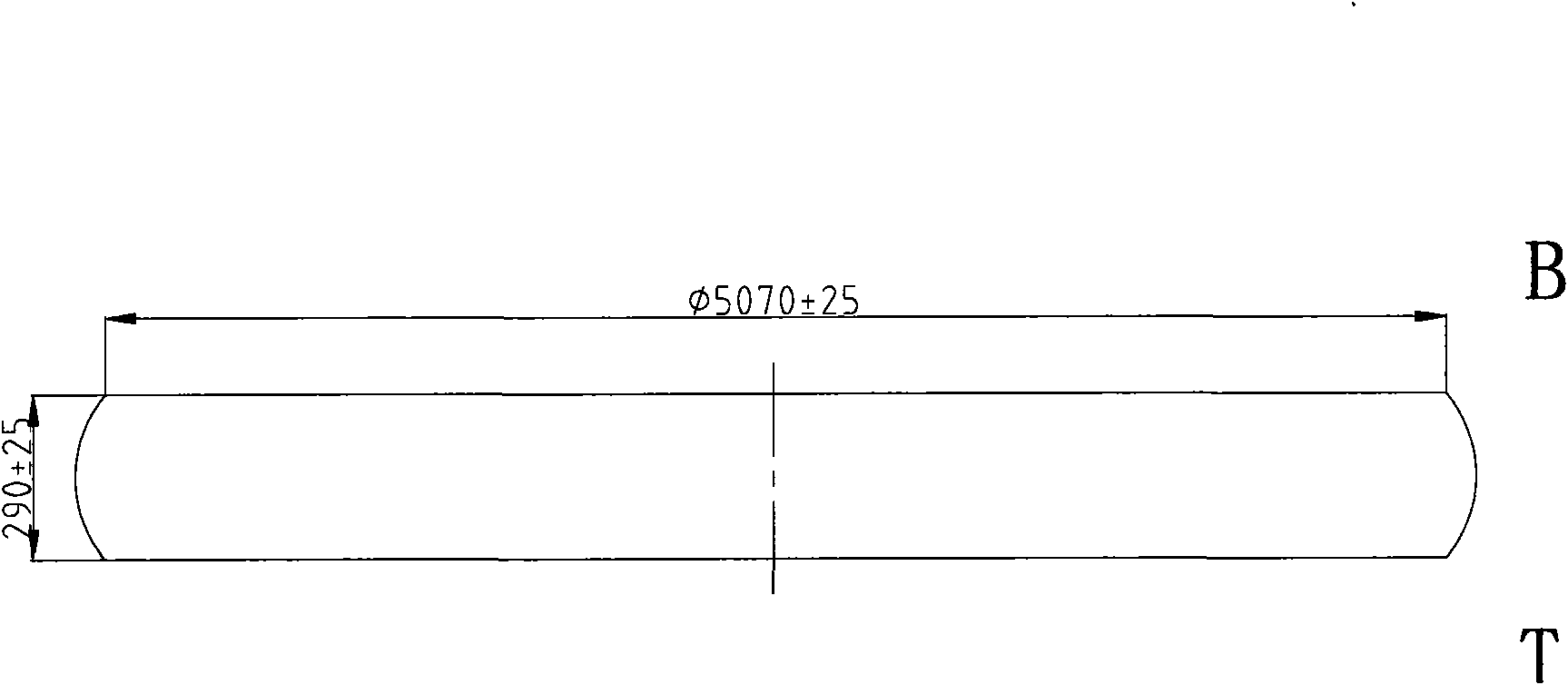

[0017] The present invention provides a forging method for the lower head forging of a million-kilowatt nuclear power reactor pressure vessel, which can be applied to the lower head with a material of 16MND5. In this example, the parameters of the lower head's delivery state: the inner radius of the ball is 2035mm , The wall thickness is 135mm, the height is 1035mm; and the smelted double vacuum ingot parameters: the diameter of the riser end is 2320mm, the diameter of the bottom end is 2055mm, and the height of the ingot is 2625mm. Therefore, the double vacuum ingot needs to be forged to meet the requirements The size requirements of the lower head.

[0018] Use the following method to forge a double vacuum ingot of 16MND5 material:

[0019] A 12,000-ton hydraulic press was used to forge a double vacuum steel ingot with a diameter of 2320 mm at the riser end, a diameter of 2055 mm at the bottom end, a height of 2625 mm, and a weight of 103 tons. The forging process is divided int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com