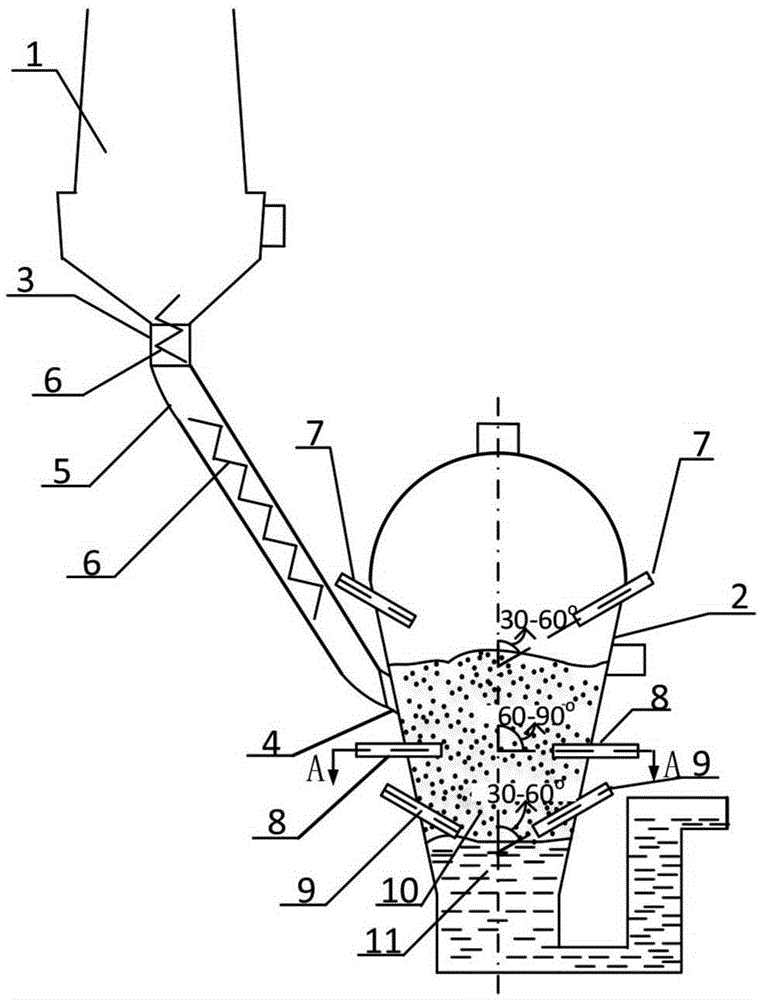

Smelting reduction iron-making device and method for avoiding re-oxidation of pre-reduction ores

A technology of iron reduction and re-oxidation, which is applied in the field of smelting reduction ironmaking, can solve the problems that the heat of the gas cannot be effectively transferred to the reduction zone, the molten iron oxide is highly corrosive, and the secondary combustion rate of the gas is low, so as to prolong the residence time , make full use of the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

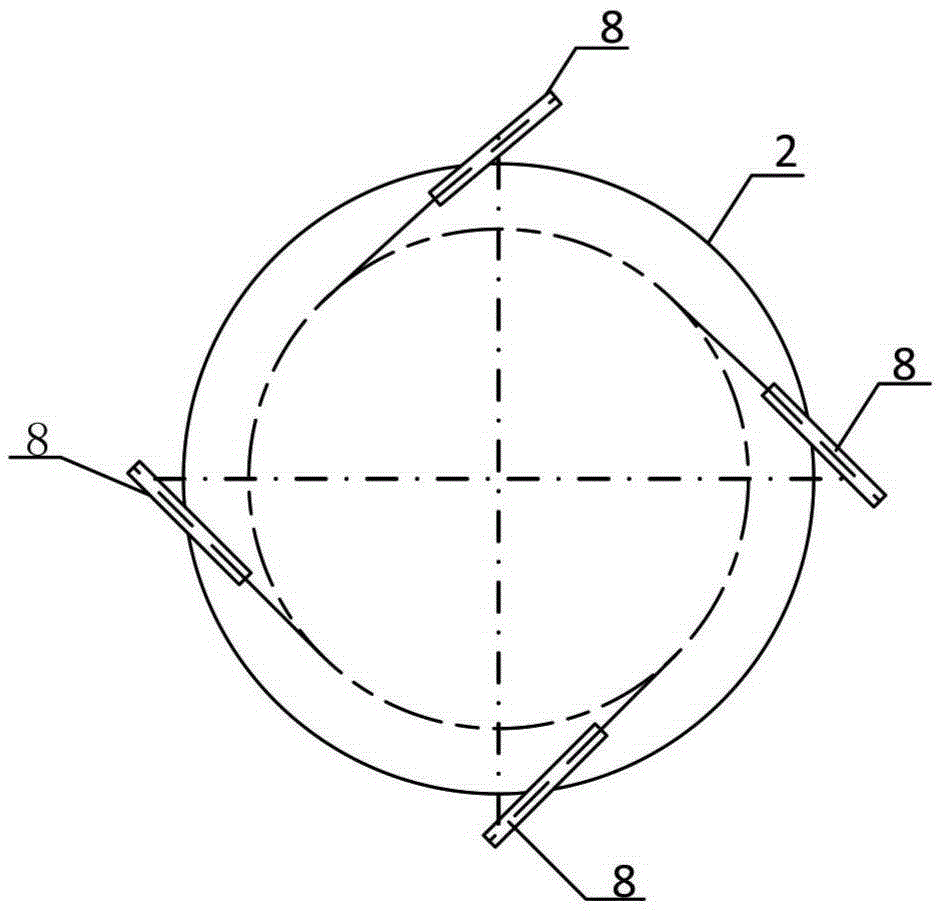

Method used

Image

Examples

Embodiment 1

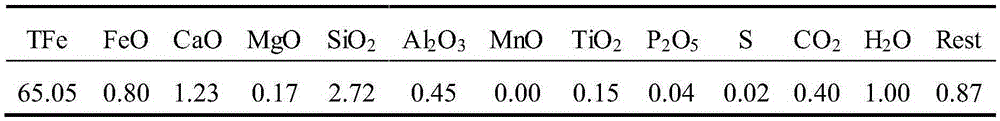

[0029] The raw material used in this embodiment is pellets, and the fuel used is pulverized coal. The chemical composition of the pellets is shown in Table 1, and the chemical composition of the coal powder is shown in Table 2.

[0030] Table 1: Chemical composition of pellets (all components listed in this table are based on mass percentage, TFe is total iron content)

[0031]

[0032] Table 2: Chemical composition (by mass percentage) of pulverized coal:

[0033]

[0034]The temperature of the pre-reduction shaft furnace is set at 850°C, and the pre-reduction pellets with a metallization rate of 90% are directly pressed into the slag layer of the iron-bathed furnace through the pre-reduction charge descending channel, and sprayed to the iron through the middle spray gun and the lower spray gun. The total amount of pulverized coal injection in the bath furnace is 950kg per ton of iron, among which, the coal injection amount of the middle layer spray gun is 90% of the to...

Embodiment 2

[0037] The raw materials used in this embodiment are the same as in Example 1, and the main operation and production parameters are as follows.

[0038] The temperature of the pre-reduction shaft furnace is set at 850°C, and the pre-reduction pellets with a metallization rate of 80% are directly pressed into the slag layer of the iron-bathed furnace through the pre-reduction charge descending channel, and sprayed to the iron through the middle spray gun and the lower spray gun. The total amount of pulverized coal injected in the bath furnace is 1048kg per ton of iron. Among them, the coal injection amount of the middle layer spray gun is 86% of the total coal consumption, and the coal injection amount of the lower layer spray gun is 14% of the total coal consumption. Oxygen is blown through the three layer spray guns The total amount is 583Nm per ton of iron 3 , wherein, the oxygen blowing volume of the upper spray gun is 5% of the total oxygen consumption, the oxygen blowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com