Photosensitive composite film and preparation method thereof

A composite film and photosensitive technology, applied in chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of poor ordering and low thermal stability, and achieve good product performance, high photothermal stability, and environmental friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

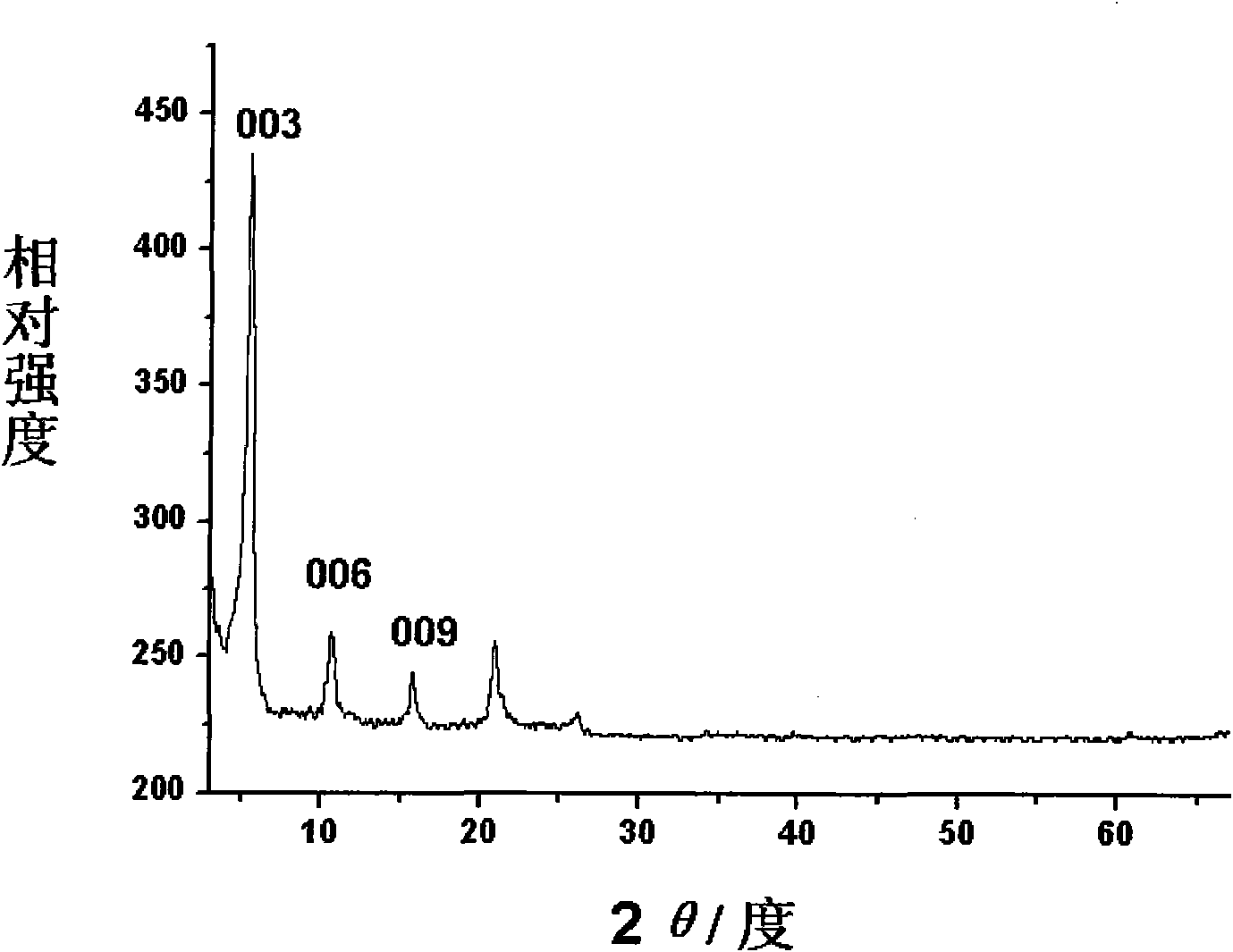

[0033]a. Mix 0.06mol Zn(NO3)2·6H2O and 0.03mol Al(NO3)3·9H2O, dissolve in 80ml deionized water from CO2 removal, dissolve 0.16mol NaOH in 80ml deionized water from CO2 removal, protect with N2 Slowly drop the lye into the mixed salt solution, stir vigorously, stop the drop when the pH is 6.0, transfer the slurry to an autoclave, crystallize at 100°C for 18 hours, and then wash by centrifugation to obtain the Zn2Al-NO3 hydrotalcite precursor ;

[0034] b. Take 2.5g Zn 2 Al-NO 3 Hydrotalcite precursor dispersed in 50ml deCO 2 dilute nitric acid to adjust the pH value to 5.5 after swelling in deionized water for 5 hours;

[0035] c. Dissolve 0.01g AMH and 0.24g PS in 100ml to remove CO 2 of deionized water;

[0036] d. the solution prepared in step c in N 2 Drop it into the hydrotalcite suspension prepared in step b under protection. After the dropping is completed, adjust the temperature to 40°C, react for 24 hours, centrifuge and wash 4 times, and dry in vacuum to obtain ...

Embodiment 2

[0045] a. Take 0.06mol Zn(NO 3 ) 2 ·6H 2 O, 0.03mol Al(NO 3 ) 3 9H 2 O mixed, dissolved in 80ml deCO 2 Dissolve 0.16mol NaOH in 80ml of deionized water 2 in deionized water, N 2 Slowly drop the lye into the mixed salt solution under protection, stir vigorously, stop the drop when the pH is 6.0, transfer the slurry to an autoclave, crystallize at 100°C for 18 hours, and then centrifuge and wash to obtain Zn 2 Al-NO 3 Hydrotalcite precursor;

[0046] b. Take 2.5g Zn 2 Al-NO 3 Hydrotalcite precursor dispersed in 50ml deCO 2 dilute nitric acid to adjust the pH value to 5.5 after swelling in deionized water for 5 hours;

[0047] c. Dissolve 0.05g AMH and 0.43g PS in 100ml to remove CO 2 of deionized water;

[0048] d. the solution prepared in step c in N 2 Drop it into the hydrotalcite suspension prepared in step b under protection. After the dropping is completed, adjust the temperature to 40°C, react for 24 hours, centrifuge and wash 4 times, and dry in vacuum to o...

Embodiment 3

[0053] a. Take 0.06mol Zn(NO 3 ) 2 ·6H 2 O, 0.03mol Al(NO 3 ) 3 9H 2 O mixed, dissolved in 80ml deCO 2 Dissolve 0.16mol NaOH in 80ml of deionized water 2 in deionized water, N 2 Slowly drop the lye into the mixed salt solution under protection, stir vigorously, stop the drop when the pH is 6.0, transfer the slurry to an autoclave, crystallize at 100°C for 18 hours, and then centrifuge and wash to obtain Zn 2 Al-NO 3 Hydrotalcite precursor;

[0054] b. Take 2.5g Zn 2 Al-NO 3 Hydrotalcite precursor dispersed in 50ml deCO 2 dilute nitric acid to adjust the pH value to 5.5 after swelling in deionized water for 8 hours;

[0055] c. Dissolve 0.005g AMH and 0.47g PS in 100ml to remove CO 2 of deionized water;

[0056] d. the solution prepared in step c in N 2 Drop it into the hydrotalcite suspension prepared in step b under protection. After the dropping is completed, adjust the temperature to 40°C, react for 24 hours, centrifuge and wash 4 times, and dry in vacuum to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com