Dewatered sludge endless grate incinerator

A technology of chain grate and incineration device, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problem that flue gas and fly ash are difficult to achieve harmlessness, fly ash cannot be harmless, and long ash residence time and other problems, to achieve the effect of long flue gas residence time, reducing flue gas flow area, and reducing fly ash share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

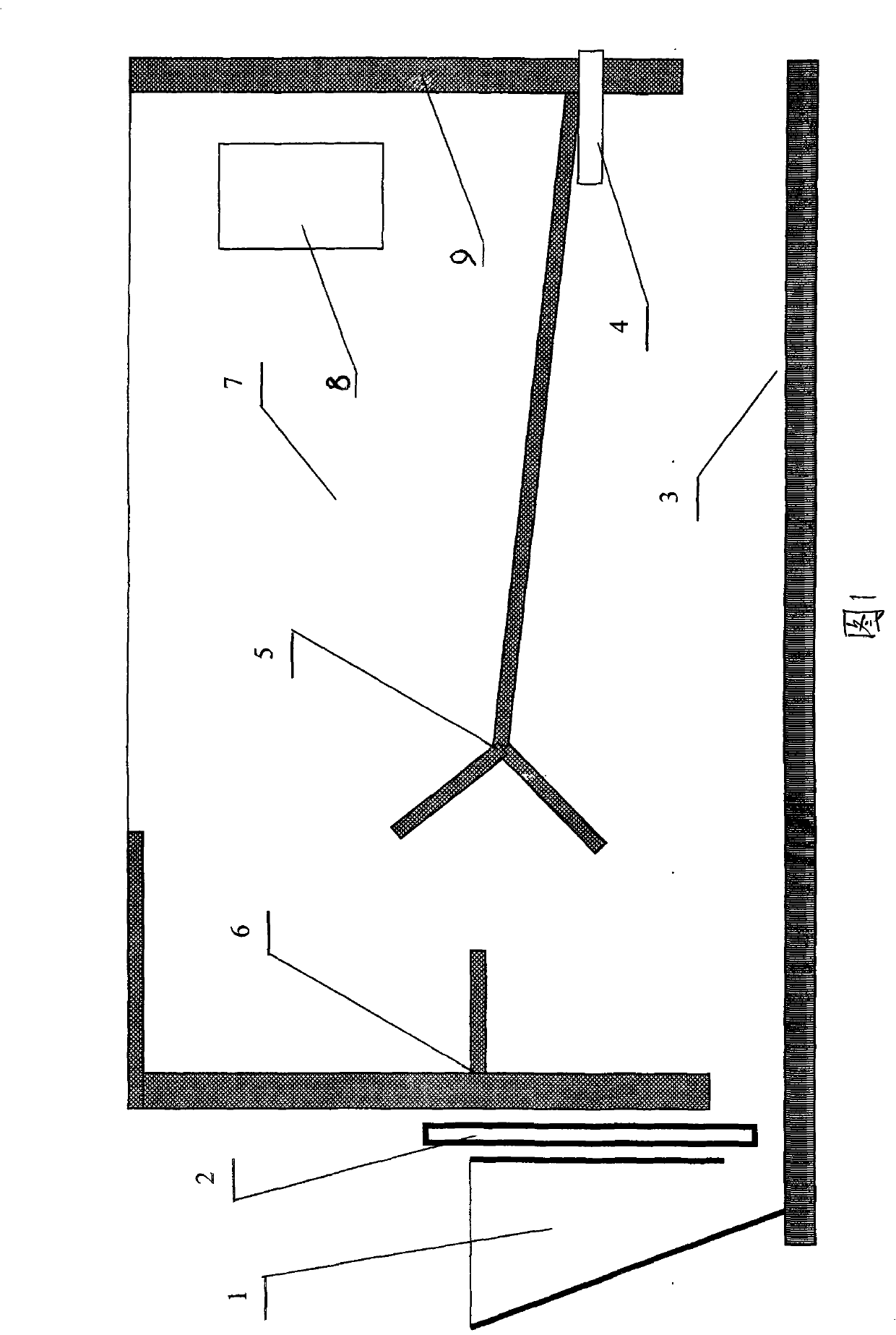

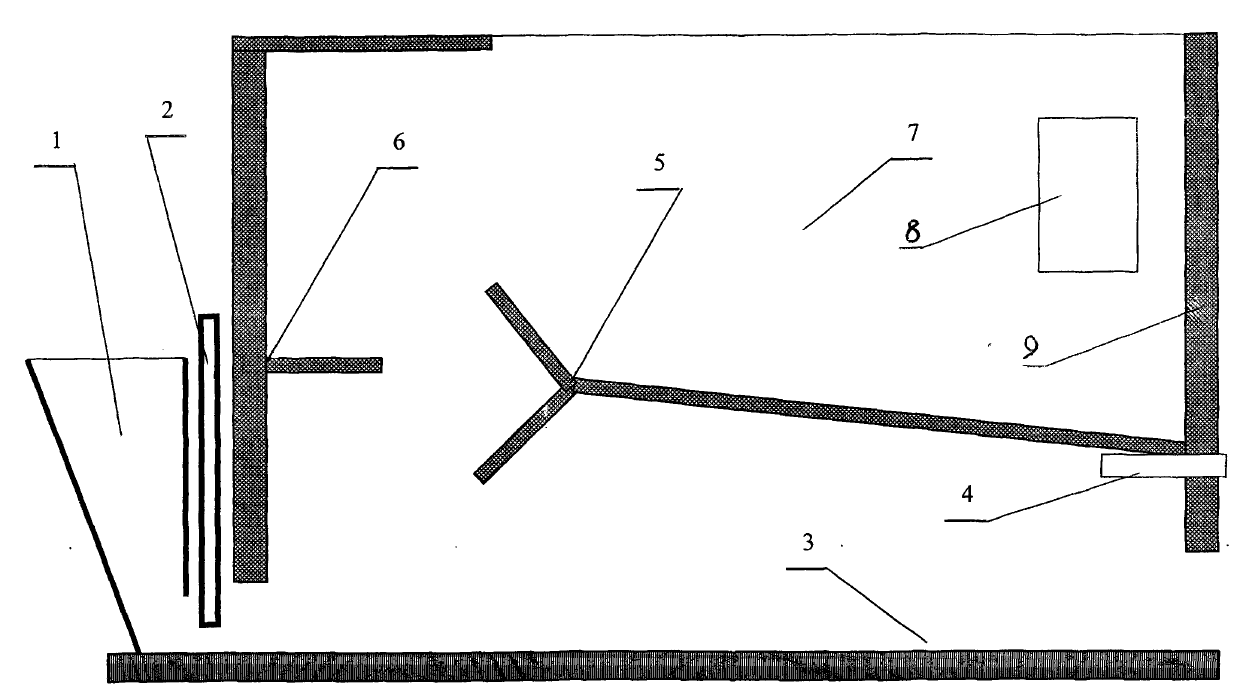

[0016] As shown in Figure 1, a chain grate incinerator with a processing capacity of 1 ton per hour of dried sludge includes a furnace, coal scuttle, coal gate, chain grate, grate air, and secondary air system. The length of chain fire grate 3 is 3 meters, and the fire grate width is 2 meters. A front arch 6 with an F-shaped longitudinal section and a rear arch 5 with a horizontal Y-shaped longitudinal section are arranged in the hearth above the chain grate. The horizontal projection length of the back arch is 2 meters. The lower branches of the back arch are inclined backwards with an inclination angle of 30 degrees; the upper branches are inclined with an inclination angle of 60 degrees. The vertical section of the F-shaped front arch is the front wall of the furnace, and the upper branch of the horizontal section is close to the furnace roof, and the vertical distance from the grate surface is 2200mm. The lower branch of the horizontal section is located between the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com