A double circulation anaerobic reactor

An anaerobic reactor and reactor technology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of low utilization rate of biogas sludge taken out of shutdown, etc., and achieve the effect of increasing the contact area, improving the effect of stirring, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] As a basic example:

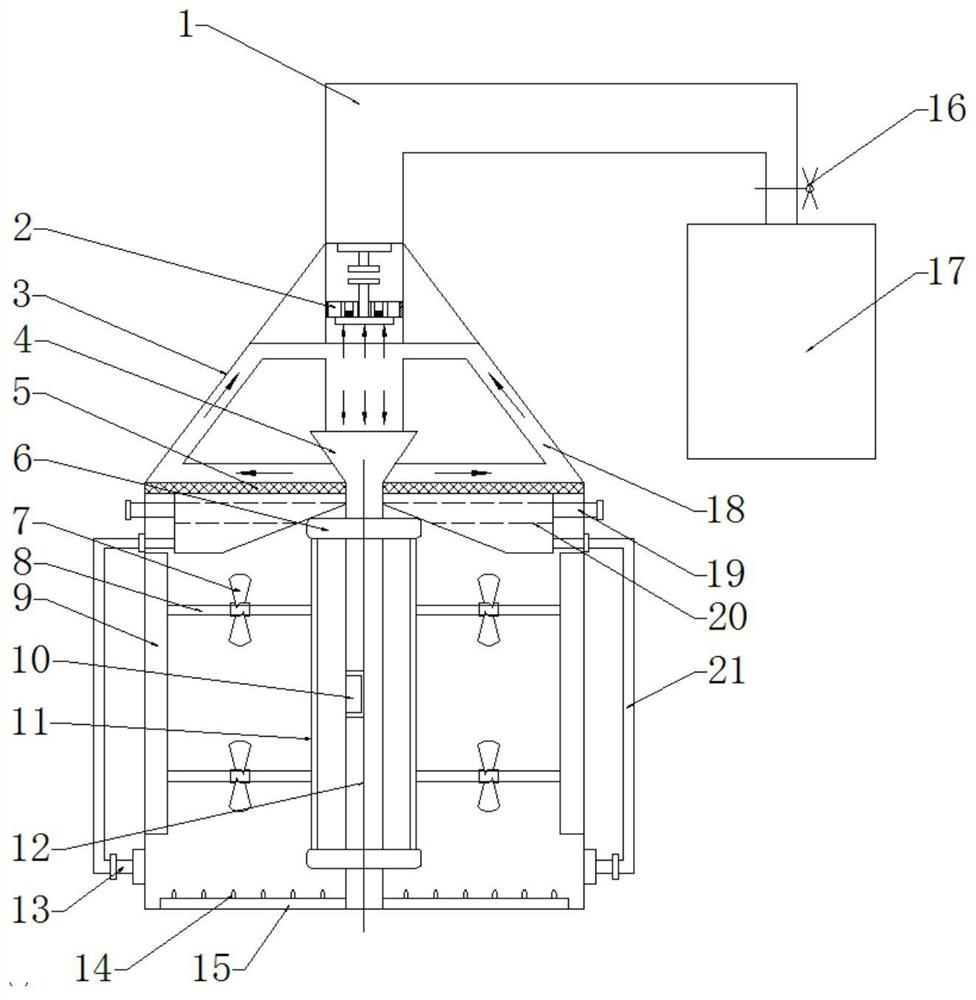

[0041] A double circulation anaerobic reactor, comprising a reactor tank 3, the bottom of the side wall of the reactor tank 3 is connected with a sludge return port 13, it is characterized in that, the reactor tank 3 is installed There is a biogas guide pipe 12 in the vertical direction, the bottom of the biogas guide pipe 12 is connected with a gas distributor 15, and the top of the biogas guide pipe 12 is provided with a gas permeable membrane 5 that separates the reactor tank 3 from top to bottom, which is breathable. A three-phase separator 20 is connected below the membrane 5, and the top of the three-phase separator 20 is open, and the gas-permeable membrane 5 covers the top of the three-phase separator 20 so that the three-phase separator 20 forms a closed structure, and the three-phase separator The bottom of the side of the device 20 is connected with a sludge return pipe 21 protruding outside the reactor tank 3, the lower end of the sludg...

Embodiment 2

[0045] This embodiment focuses on the improvements compared with the above-mentioned embodiments, and the similarities will not be repeated. In this embodiment, the biogas outlet at the top of the reactor tank 3 is connected with a gas outlet pipe 1, and the gas outlet pipe 1 is connected with a biogas storage tank 17, and a storage tank valve 16 is installed on the outlet pipe 1. The gas outlet pipe 1 and the biogas storage tank 17 of this embodiment can directly collect excess overflowing biogas, which facilitates subsequent biogas utilization in one step, makes the whole processing process simpler and faster, and improves work efficiency.

Embodiment 3

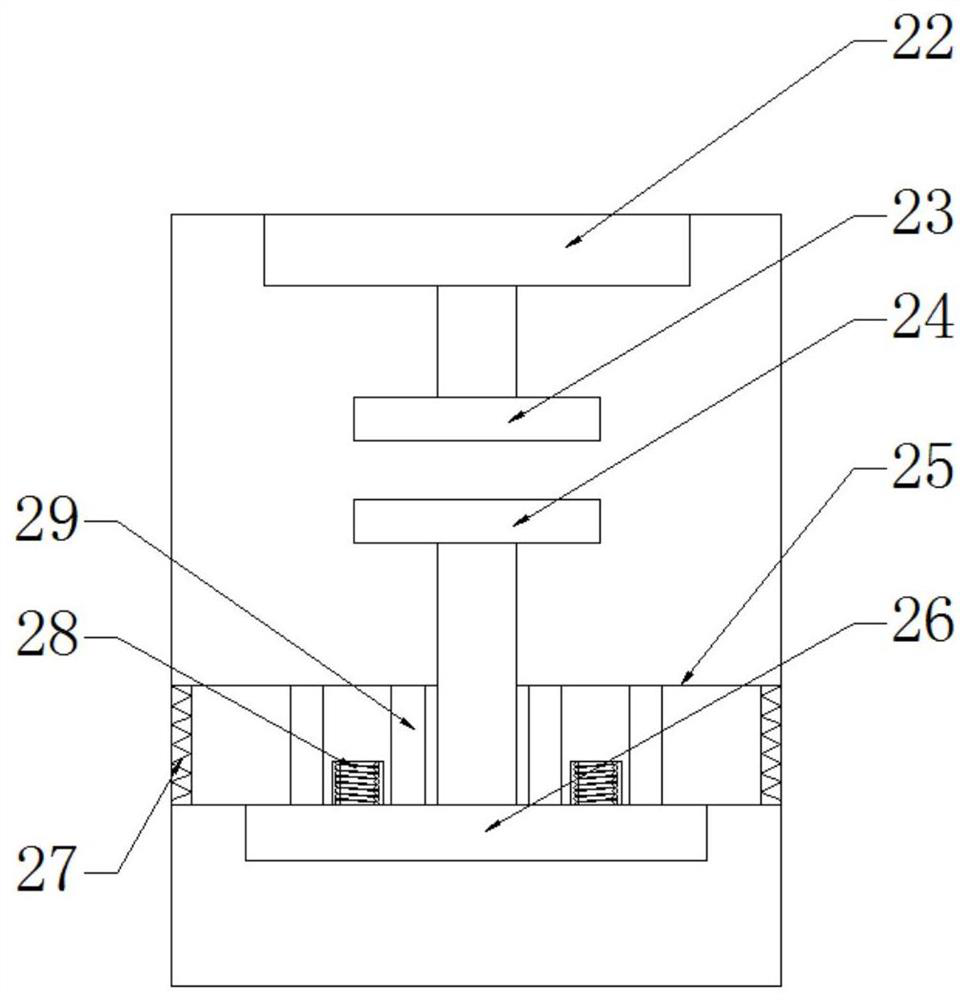

[0047] This embodiment focuses on the improvements compared with the above embodiments, and the similarities will not be repeated. In this embodiment, the side of the piston 25 is connected with a sealing ring 27 . The piston 25 of this embodiment is connected with a sealing ring 27, which can ensure that the piston 25 does not leak gas while moving, thereby ensuring that the gas outlet valve 2 can always realize the function of opening and closing in time, and avoiding the danger of biogas leakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com