Treatment method of magnesium alloy melt

A processing method and technology for magnesium alloys, applied in the field of metal materials and metallurgy, can solve the problems of reduced refining effect, low stirring strength, influence on alloy composition, etc., and achieve the effects of uniform structure and composition, good processing effect and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

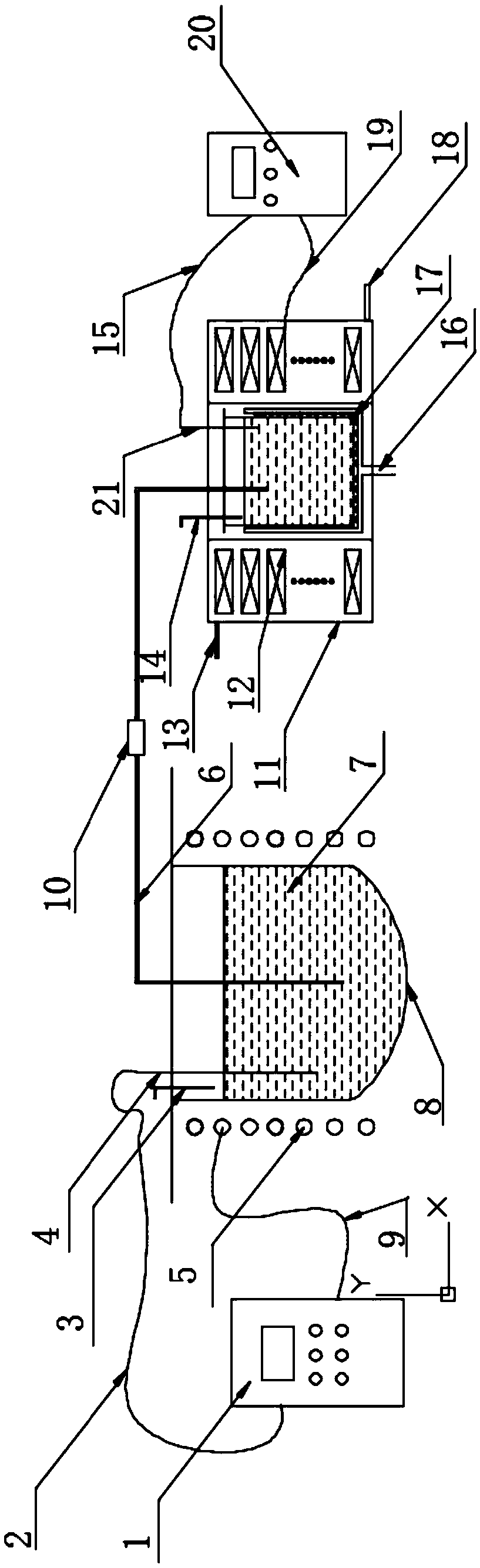

Method used

Image

Examples

Embodiment 1

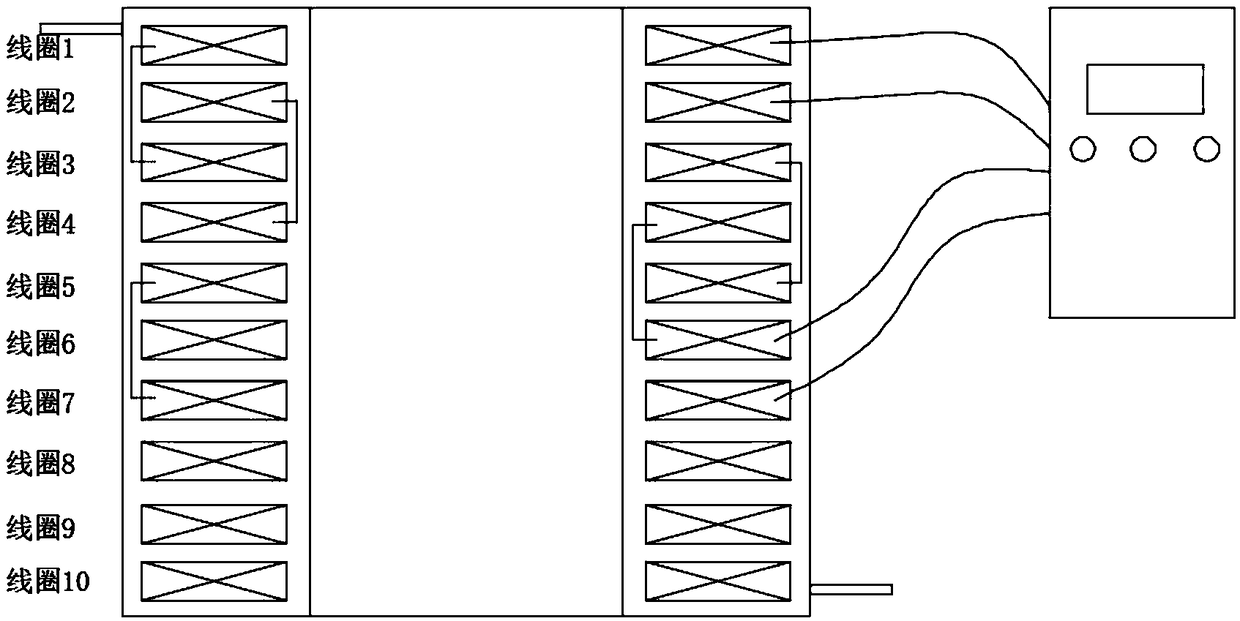

[0034] Place the 500Kg commercial magnesium alloy AZ80 material in a melting furnace to melt, and then refining for 40 minutes. After the refining, the melt is allowed to stand at 710°C; before the melt is processed, an electromagnetic generation system containing an electromagnetic coil set is installed The coil group is composed of 6 groups of coils. Connect coil 1, coil 3, and coil 5 in series to form a coil group and pass a sharp waveform pulse current with a frequency of 20Hz, current of 100A and a duty cycle of 50%; coil 2, coil 4, and coil 6 in series to form another coil group Parallel frequency is 20Hz, current is 100A with a sharp waveform pulse current with duty ratio of 50%, and the phase difference between the two coil groups is set to 90°C. Place the mold in an electromagnetic generation system with cooling function, then transfer the static melt to a mold with a cooling rate of 2°C / s, and start the electromagnetic generation system to process the alloy melt for 1...

Embodiment 2

[0037] Place the 500Kg commercial magnesium alloy AZ80 material in a melting furnace for melting, and then refining for 40 minutes. After the refining, the melt is allowed to stand at 710°C; before the melt is processed, an electromagnetic generation system containing an electromagnetic coil set is installed The coil group is composed of 6 groups of coils. Connect coil 1, coil 3, and coil 5 in series to form a coil group and pass a sharp waveform pulse current with a frequency of 20Hz, current of 100A and a duty cycle of 50%; coil 2, coil 4, and coil 6 in series to form another coil group The parallel frequency is 40Hz, the current is 150A with a sharp waveform pulse current with a duty cycle of 50%, and the phase difference between the two coil groups is set to 90°C. Place the mold in an electromagnetic generation system with cooling function, then transfer the static melt to a mold with a cooling rate of 2°C / s, and start the electromagnetic generation system to process the al...

Embodiment 3

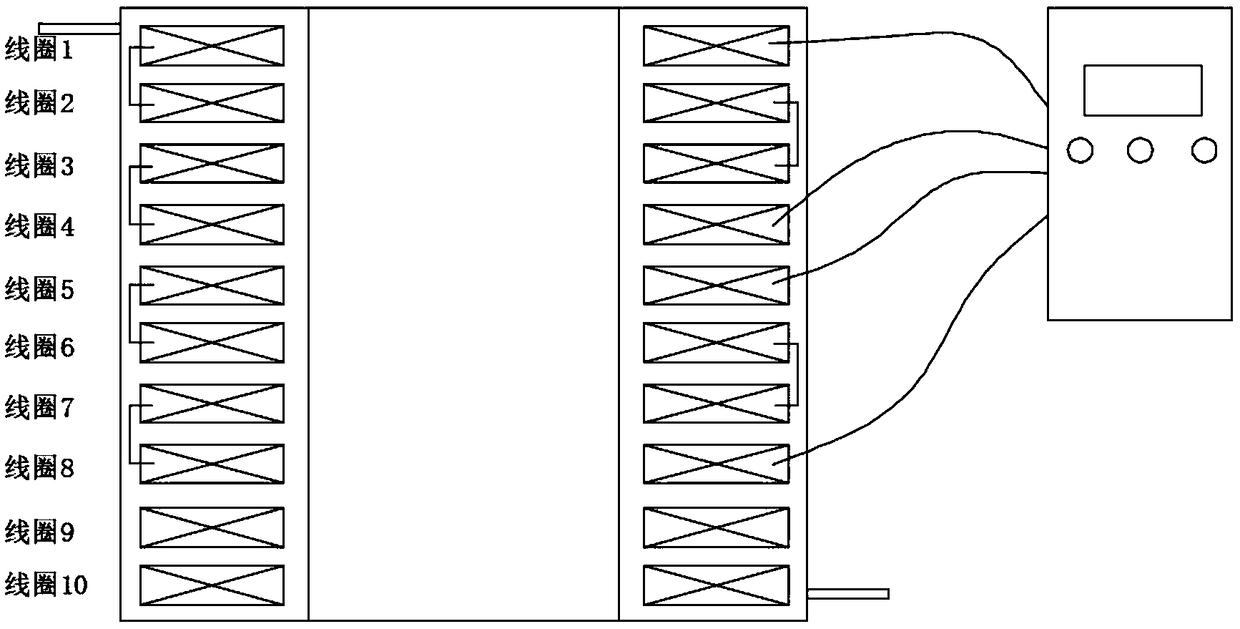

[0040] Place the 200Kg commercial magnesium alloy AZ80 material in a melting furnace for melting, and then refining for 20 minutes. After the refining, the melt is allowed to stand at 700°C; before the melt is processed, an electromagnetic generation system containing an electromagnetic coil set is installed The coil group is composed of 6 groups of coils. Connect coil 1, coil 2, and coil 3 in series to form a coil group and pass a sharp waveform pulse current with a frequency of 20Hz, current of 100A and a duty cycle of 60%; coil 4, coil 5, and coil 6 are connected in series to form another coil group The parallel frequency is 20Hz, the current is 100A with a sharp waveform pulse current with a duty ratio of 3%, and the phase difference between the two coil groups is set to 90°C. Place the mold in an electromagnetic generation system with cooling function, then transfer the static melt to a mold with a cooling rate of 30°C / s, and start the electromagnetic generation system to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com