Mixing transporter applied to dry concrete

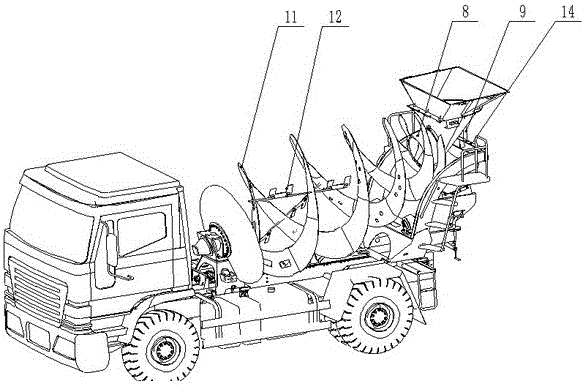

A technology for mixing trucks and concrete, which is applied to cement mixing devices, mixing operation control devices, clay preparation devices, etc., can solve the problems that concrete mixer trucks cannot be used and cannot be transported due to long transportation distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

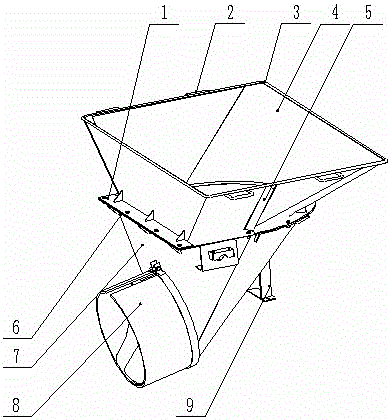

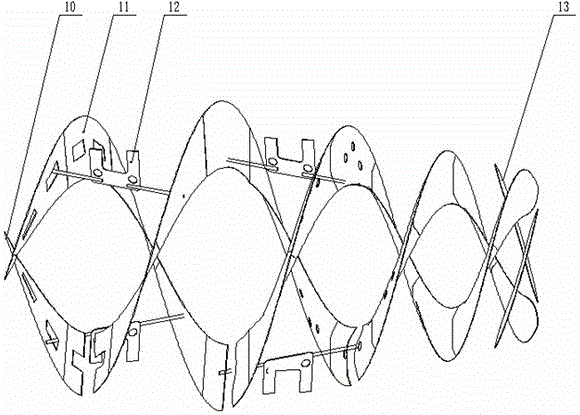

[0016] figure 1 Among them, the feeding hopper of the present invention is connected by bolts from the upper and lower parts, which are detachable. The upper bucket connecting plate 1, the hoisting handle 2, the surrounding edge 3, the upper bucket wall 4, and the reinforcement plate 5 are welded together to form the upper half of the feeding hopper; the lower bucket connecting plate 6, the lower bucket wall 7, after welding The material guide tongue (abbreviated as tongue) 8 is stuck on the feed hopper, the lower hopper is supported by the lower hopper 9 and installed on the frame tail of the mixer truck, and the tongue 8 extends into the mixing drum. The tongue consists of two parts, an arc-shaped inner plate and a cylindrical outer plate. The arc-shaped inner plate is welded with the lower hopper, and the cylindrical outer plate is clamped on the outside of the arc-shaped inner plate with a clamp. The blades are composed of two main helical blades, and each main helical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com