Production process capable of industrially synthesizing dydrogesterone

A production process, the technology of dydrogesterone, which is applied in the field of industrialized preparation of dydrogesterone raw materials, can solve the problems of progesterone imitation in regions where it cannot be imitated, it is not easy to scale up, and the yield is not high, and achieves important economic and social value, Easy to scale up production and less reaction by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The preparation method of this embodiment is shown in Scheme 10;

[0077]

[0078] Scheme 10

Embodiment 1

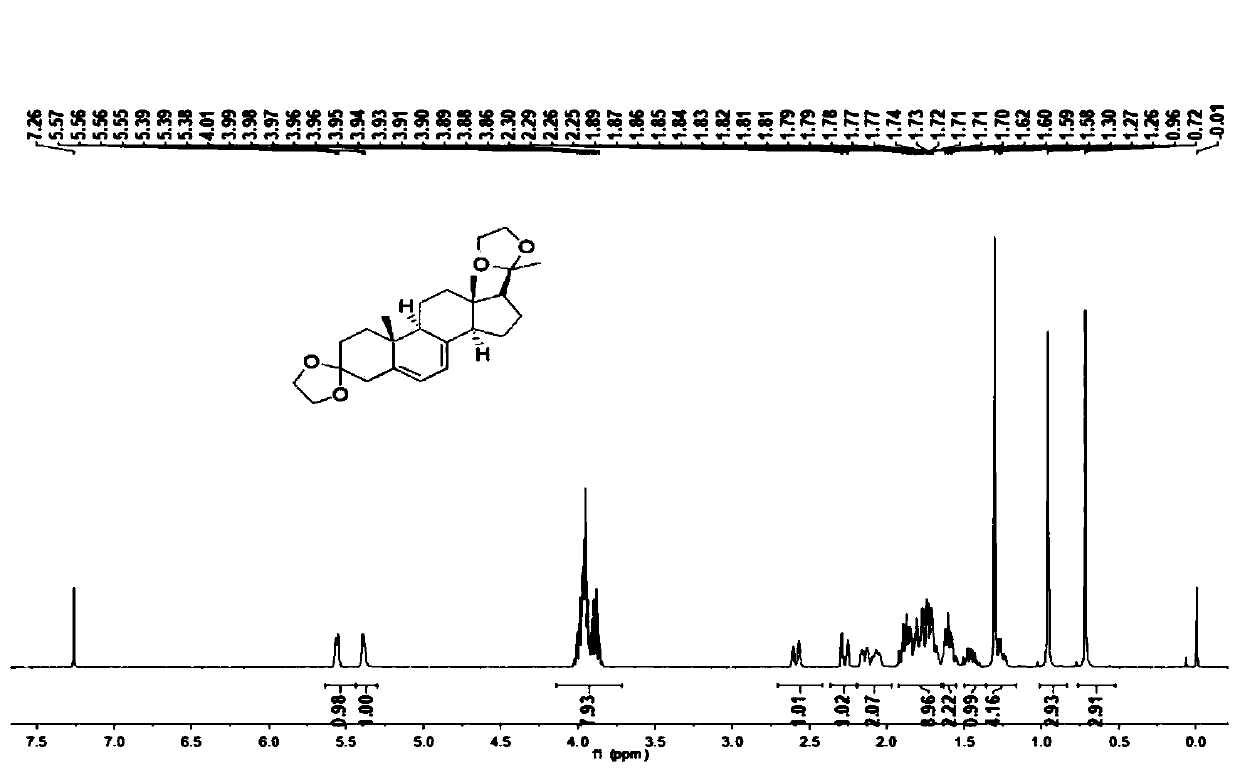

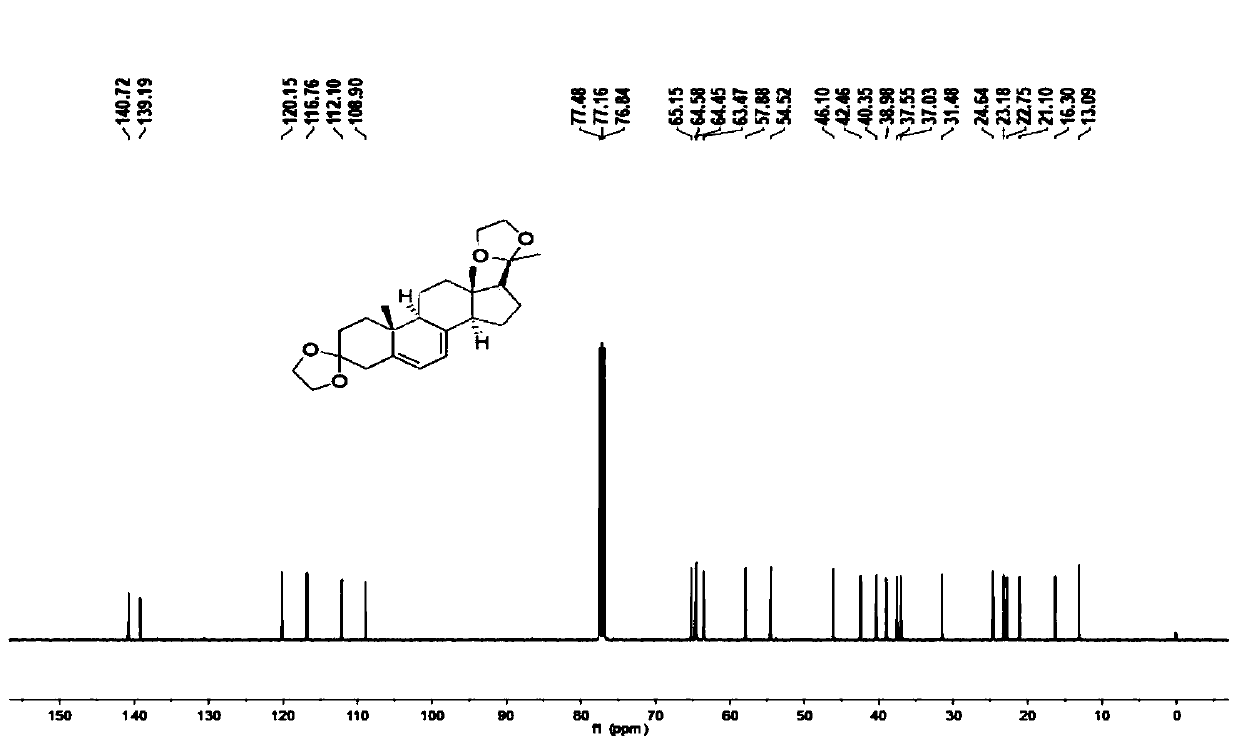

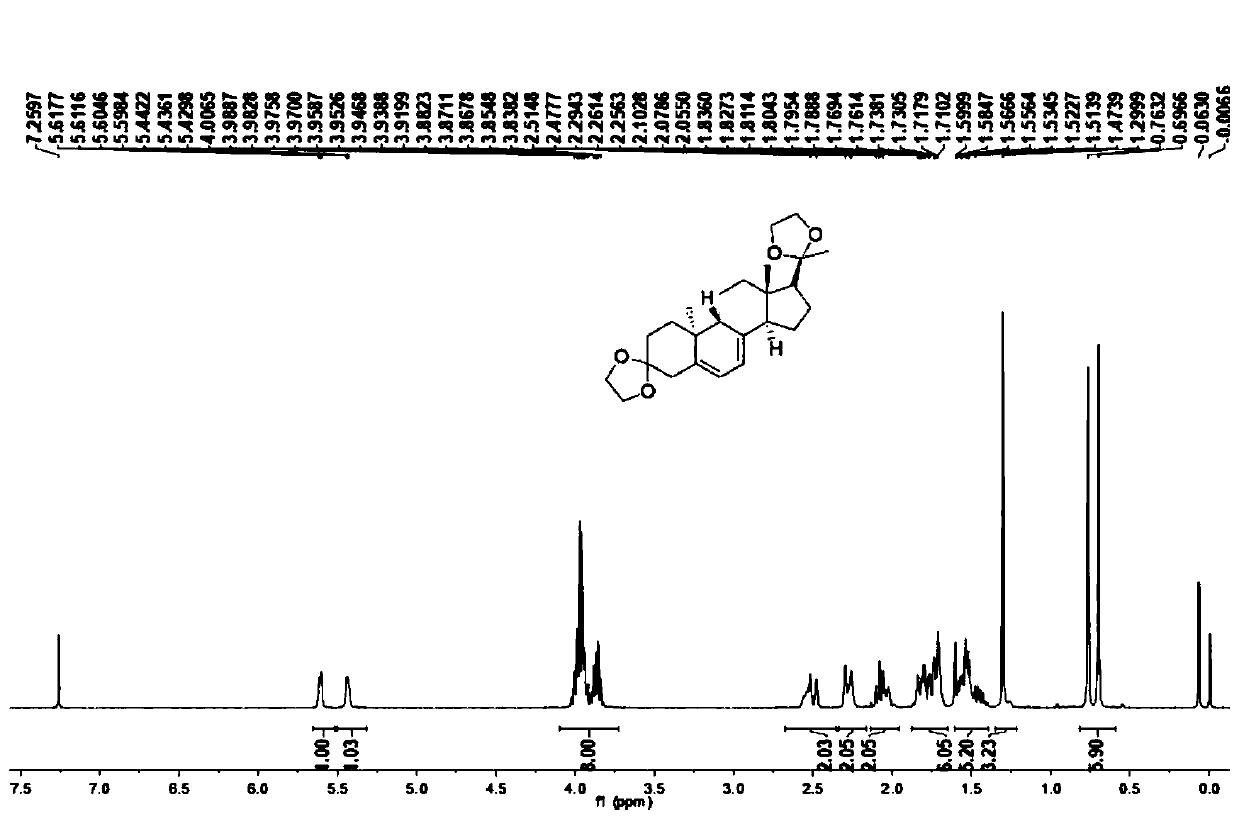

[0080] Weigh 2kg of progesterone (compound 2) into a 20L reaction tank, then add 4L of ethylene glycol, 5.5L of tetrahydrofuran, 0.1L of acetyl chloride in sequence, slowly add 2L of trimethyl orthoformate, and control the temperature at 35±5 ℃, react for 2 hours ± 10 minutes, add 0.2 L of pyridine to quench the reaction, cool at -10 °C ± 5 °C for 0.5 hours, filter, wash with 6 L of water and 3 L of acetone in turn, drain, and dry in vacuum below 40 ° C to obtain the compound 3 crude product.

[0081] Put the crude product of compound 3 into a 20L reaction tank, add 6L of acetone and 4ml of pyridine, heat in a water bath to reflux, stir for 1 hour, cool at -10°C±5°C for 0.5 hour, filter with suction, and dry in vacuo at 40°C overnight to obtain compound 3. Pure product, yield 91%.

Embodiment 2

[0083] Respectively replace tetrahydrofuran with methyl tert-butyl ether, isopropyl ether, glyme or glyme, others are the same as Example 1, and the productive rate of compound 3 is respectively 80%, 83%, 89% and 85% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com