Red mud raw material-based non-steamed brick and production method thereof

A technology that avoids steaming bricks and red mud is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. It can solve the problems of low utilization rate of industrial waste residues, achieve simple production and process maintenance conditions, and improve gelation. Active, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

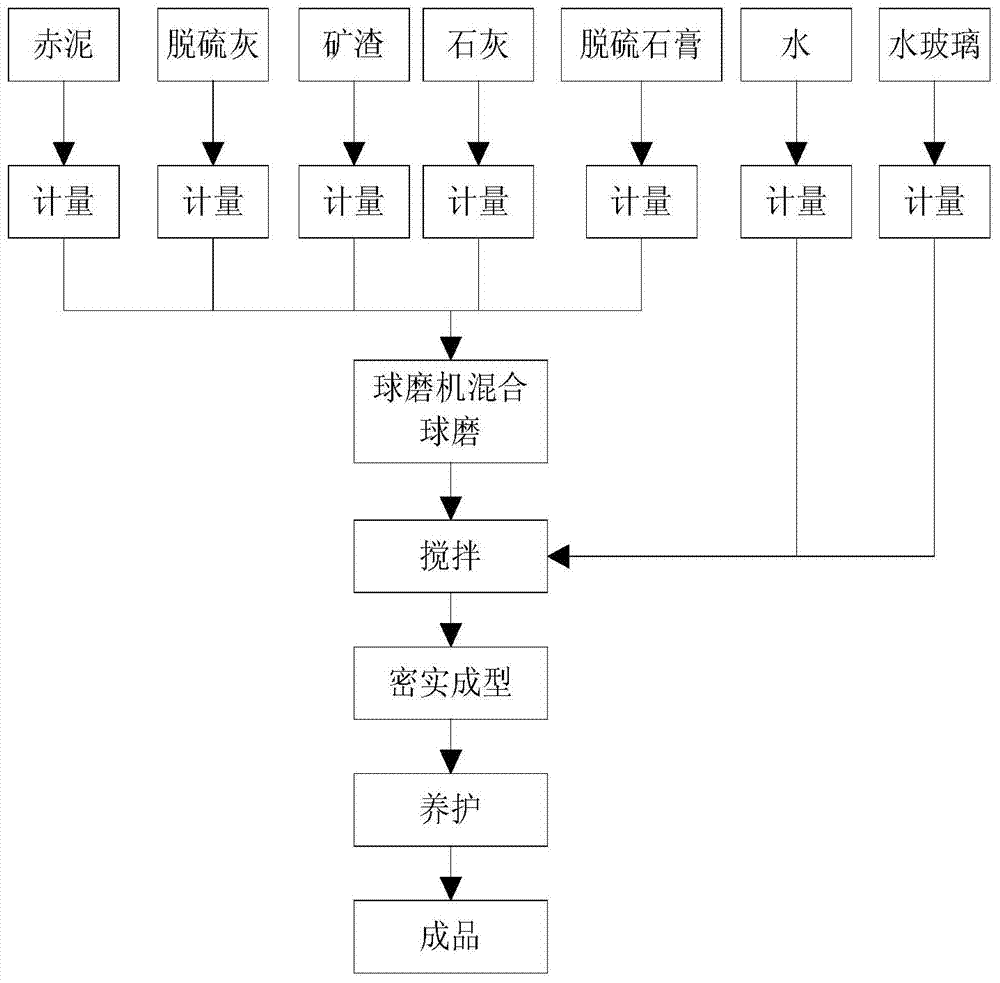

[0025] The preparation method includes: drying process, weighing ingredients and grinding and mixing process, the specific method process is as follows:

[0026] (1) Drying process: Dry red mud, desulfurized ash, slag, lime, and desulfurized gypsum with a dryer to remove free water;

[0027] (2) Grinding process: put red mud into a ball mill and grind until the specific surface area is ≥600m 2 / kg;

[0028] (3) Weighing ingredients and mixing process: Weigh ingredients according to the above raw material formula, and then put the above three raw materials into a ball mill to mix and grind until the specific surface area is ≥ 600m 2 / kg;

[0029] (4) Raw material ratio and molding: red mud 70-80%; desulfurized ash 0-10%; slag 0-10%; lime 5%; desulfurized gypsum 8-10%; water glass 0-5%, plus water , the amount of water added accounts for 30-40% of the total amount of ingredients; fully stir in the mixer, pour into the mold, and place it on the vibrating table for compact mold...

Embodiment 1

[0033] Example 1: Experiments and performance tests were carried out with reference to the national standard "Test Methods for Wall Bricks" GB / T2542-92.

[0034] The raw materials used in the test were dried with a dryer and then ground, and then the ingredients were weighed and put into a ball mill for mixing. Put the mixture into the mixer and add 30-40% water, mix well, pour it into the mold, put it on the vibrating table for compact molding, and then perform standard curing for 1-3 days to demould, and finally transport the site for natural curing until 28 days. Finished products are available.

[0035] Table 1 Effects of different dosages on the mechanical properties of unburned bricks

[0036]

[0037] The qualified judgment value and classification of the mechanical properties of unburned bricks according to the national standard are shown in Table 2 below.

[0038] Table 2 Judgment criteria for strength grades

[0039] strength level

[0040] After 28 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com