Carbon film and LiFePO4 composite nm conductive material and its synthesis method

A nano-conductive, carbon film technology, applied in conductive materials, conductive materials, conductors, etc., can solve the problems of unavailability, poor electrical conductivity, and high requirements for preparation conditions, and achieve the effect of reducing preparation requirements and energy consumption, and being easy to prepare.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

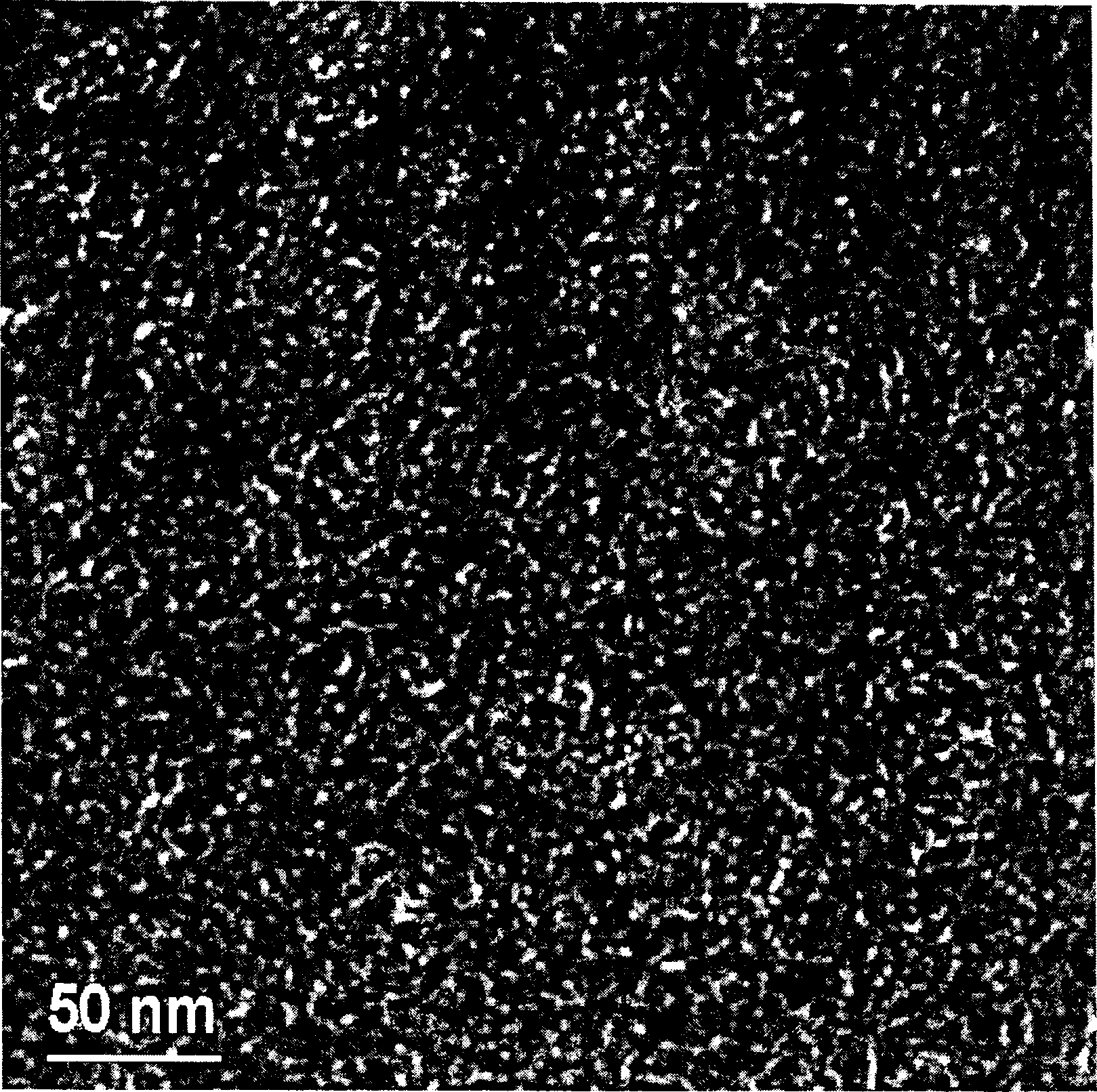

[0020] Example 1. Add 2 mL of glycerol dropwise to 10 mL of distilled water, and stir evenly. Add 3.45g LiNO under high speed stirring 3 , 9g FeC 2 o 4 9H 2 O and 5.8 g NH 4 h 2 PO 4 , after stirring for 1 hour, in N 2 Dry at 120°C under atmosphere. then in N 2 Under the atmosphere, the temperature was raised to 600°C, baked for 24 hours, and after natural cooling, a black carbon film and LiFePO 4 Composite nano conductive new material; the carbon film content of the material is 2wt%, and the conductivity is 10 -5 S cm -1 Magnitude.

[0021] Example 2. Add 20mL of glycerol dropwise to 10mL of distilled water and stir evenly. Add 3.45g LiNO under high speed stirring 3 , 9g FeC 2 o 4 9H 2 O and 5.8 g NH 4 h 2 PO 4 , after stirring for 1 hour, in N 2 Dry at 120°C under atmosphere. then in N 2 Under the atmosphere, the temperature was raised to 800 ° C, baked for 12 hours, and after natural cooling, a black carbon film and LiFePO were obtained. 4 Composite n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com