Preparation method for semisolid metal and alloy pulp or blank

A semi-solid metal and alloy technology, which is applied in the field of semi-solid metal preparation, can solve the problems of spherical primary phases that are not too round and coarse, and achieve the effects of good structure, reduced oxidation, and avoiding oxidation or splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: A356 aluminum alloy liquid

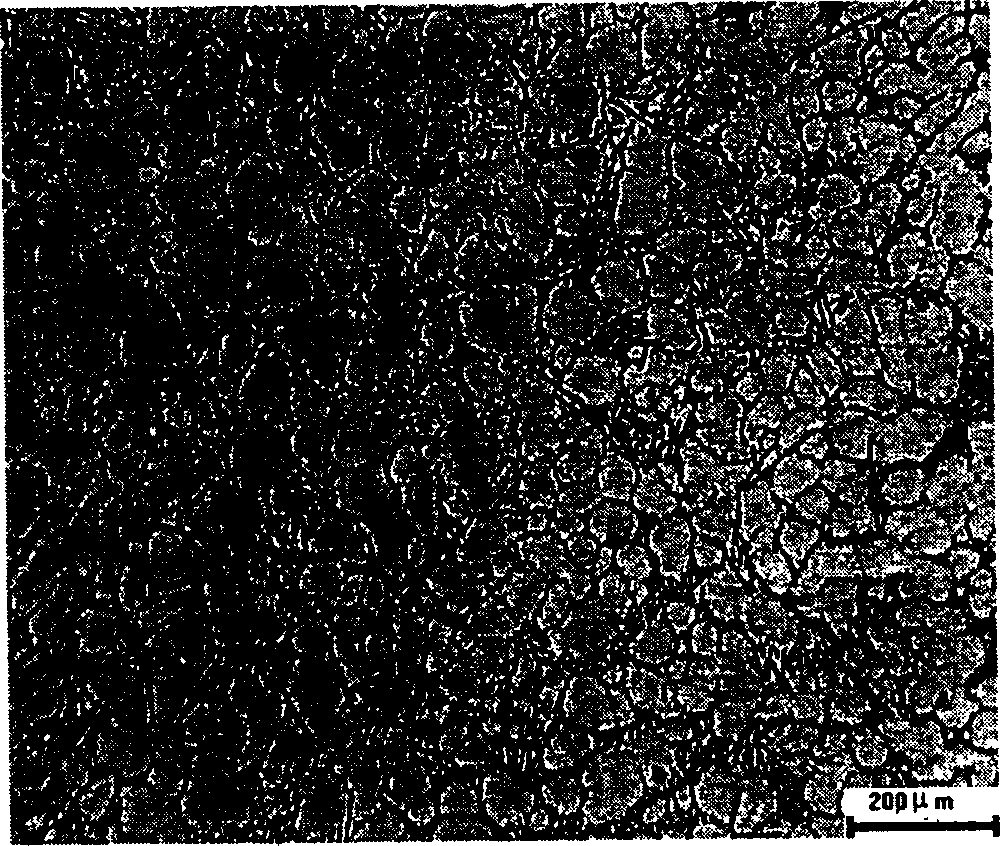

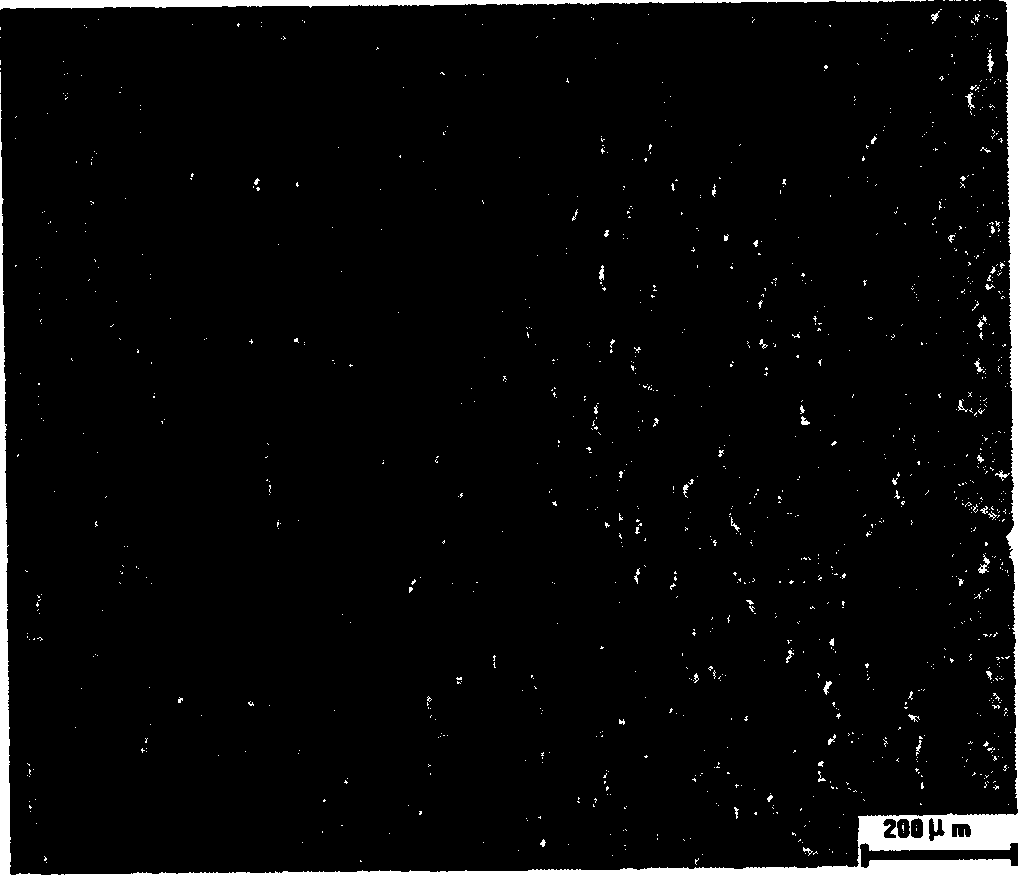

[0029] A resistance melting furnace is used to produce A356 aluminum alloy liquid with a superheat of 15°C. At a pouring height of 450 mm, the superheated A356 aluminum alloy liquid is directly poured into a stainless steel preparation crucible, that is, a receiving container. When the A356 aluminum alloy liquid When partially solidified, the semi-solid A356 aluminum alloy slurry with spherical primary crystals can be obtained, and its structure is as follows figure 1 As shown; the semi-solid A356 aluminum alloy slurry that will prepare the crucible and accept the container together with the spherical primary crystal therein is moved in a tissue controller, and the tissue controller is made of a medium-frequency electromagnetic induction coil, and its power is controlled so that the Prepare the crucible, that is, the receiving container, and further cool the semi-solid A356 aluminum alloy slurry with spherical primary crystals the...

example 2

[0032] Example 2: AZ91D magnesium alloy liquid

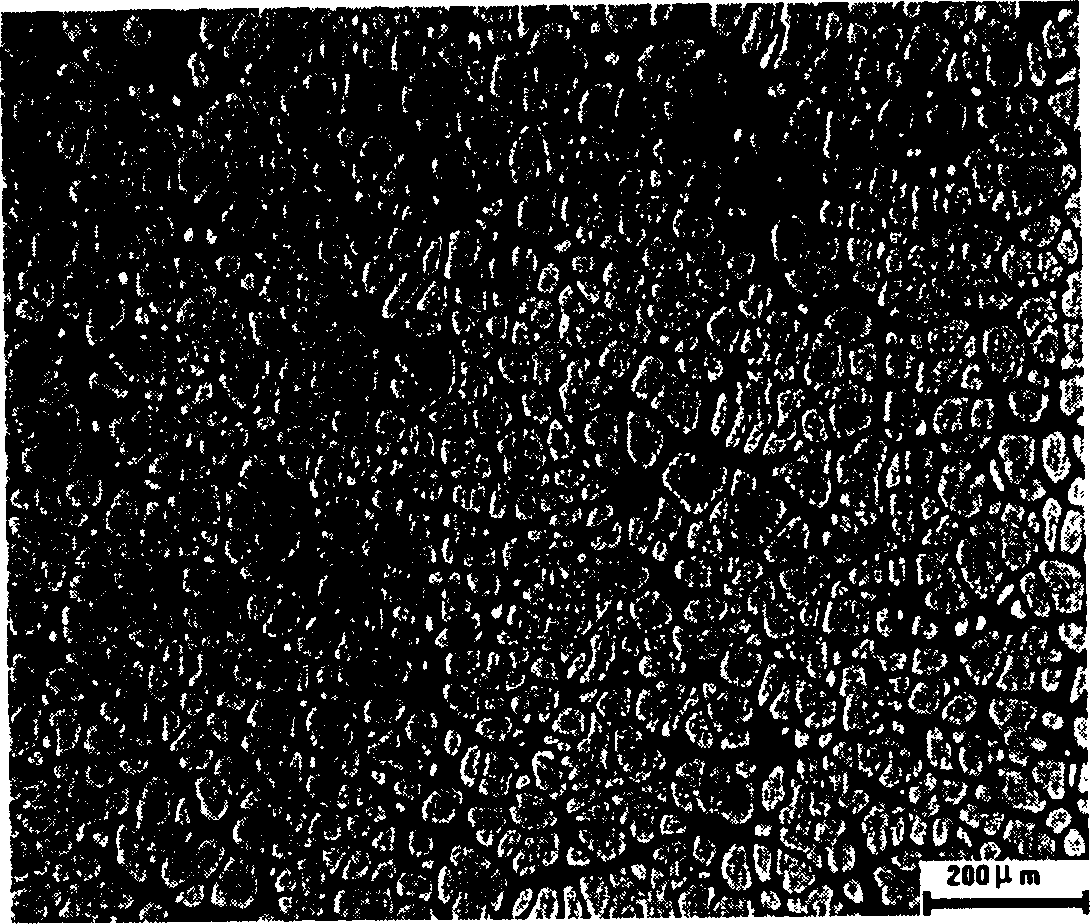

[0033] Using resistance melting furnace to produce AZ91D magnesium alloy liquid with a superheat of 10 ℃, at a pouring height of 300mm and SF 6 Mixed gas with air (including SF 6 Under the protection of 1%), the superheated AZ91D magnesium alloy liquid is directly poured into the stainless steel preparation crucible, that is, the receiving container. When the AZ91D magnesium alloy liquid is partially solidified, the semi-solid AZ91D magnesium alloy with spherical primary crystal can be obtained slurry, the organization of which is Figure 5 As shown; the preparation crucible is the receiving container and the semi-solid AZ91D magnesium alloy slurry of the spherical primary crystal therein is moved to a tissue controller, which is composed of a medium-frequency electromagnetic induction coil, and its power is controlled so that the Prepare the crucible, that is, the receiving container, and further cool the semi-solid AZ91D mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com