Loaded type nickel-based catalyst used for slurry bed methanation, and preparation method and application thereof

A nickel-based catalyst and slurry bed technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the specific surface area crystal phase structure of the catalyst in the solution combustion process Difficult to control, poor catalyst reproducibility, limited application, etc., to achieve the effects of improved catalytic performance and stability, reduced preparation energy consumption, and shortened preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 6.2g nickel nitrate, fully dissolve in 3.7ml water, add 1.3g ethylene glycol to the solution, then slowly add γ-Al 2 o 3Carrier powder 5g, impregnated at room temperature for 24 hours under stirring conditions, pour the suspension into a ceramic evaporating dish, put it in a muffle furnace, heat to 300°C, and burn by itself, collect the remaining powder after combustion, grind and granulate to 100 In a fixed bed, at 550°C, the volume composition is 5% H 2 with 95%N 2 , the space velocity is 2000ml / (g·h) and reduced for 4h to obtain the methanation nickel-based catalyst. The catalyst composition is: NiO 24wt.%, carrier 76wt.%.

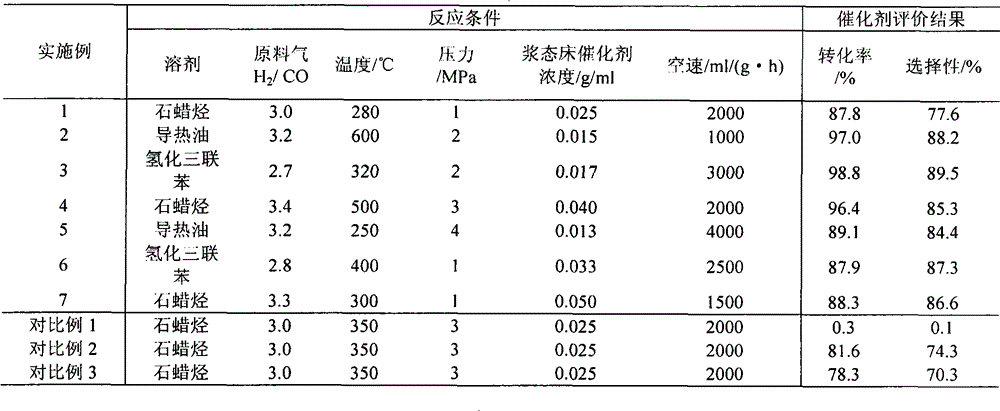

[0034] The specific conditions and results of the activity evaluation of the catalyst in the reaction of syngas to methane are shown in Table 1. Specific steps are as follows:

[0035] A certain quality of the above-mentioned catalyst and 120ml of liquid solvent are injected into the reactor of a 250ml slurry bed reactor. At room temp...

Embodiment 2

[0037] Weigh 9.9g nickel nitrate, 0.2g cobalt nitrate, fully dissolve in 10ml water, add 5.1g urea to the solution, then slowly add ZrO 2 Carrier powder 5g, impregnated at room temperature for 6h under stirring conditions, pour the suspension into a ceramic evaporating dish, put it in a muffle furnace, heat to 600°C, and burn by itself, collect the remaining powder after combustion, grind and granulate to 200 At 650°C in a fixed bed, the volume composition is 10% H 2 with 90%N 2 , the space velocity is 3000ml / (g·h) and reduced for 5h to obtain the methanation nickel-based catalyst. The catalyst is composed of: NiO 33wt.%, carrier 66wt.%, additive (cobalt oxide) 1wt.%.

[0038] The specific conditions and results of the activity evaluation of the catalyst in the reaction of syngas to methane are shown in Table 1. Concrete steps are as shown in embodiment 1.

Embodiment 3

[0040] Weigh 8.7g of nickel nitrate, 0.3g of lanthanum nitrate, fully dissolve in 15ml of water, add 1.9g of urea to the solution, and then slowly add SiO 2 Carrier powder 5g, impregnated at room temperature for 12h under stirring conditions, pour the suspension into a ceramic evaporating dish, put it in a muffle furnace, heat to 400°C, and burn by itself, collect the remaining powder after combustion, grind and granulate to 150 At 650°C in a fixed bed, the volume composition is 15% H 2 with 85%N 2 , Space velocity 1000ml / (g·h) condition reduction 6h, obtains the methanation nickel-based catalyst. The catalyst is composed of: 30wt.% of NiO, 69wt.% of carrier, and 1wt.% of additive (lanthanum oxide).

[0041] The specific conditions and results of the activity evaluation of the catalyst in the reaction of syngas to methane are shown in Table 1. Concrete steps are as shown in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com