Transmission front shell and back shell mixed-flow production line and production method

A production method and the technology of the front shell, which are applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems such as the process method of the mixed flow production of the shell that has not been seen, and achieve the effect of low cost and equipment investment optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

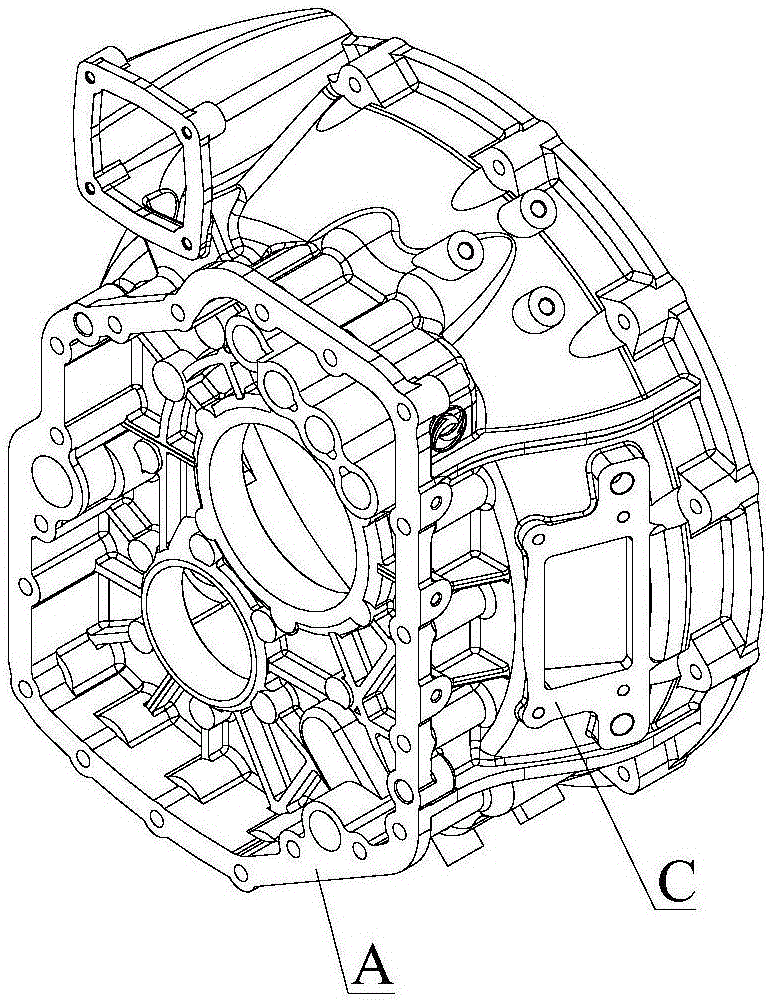

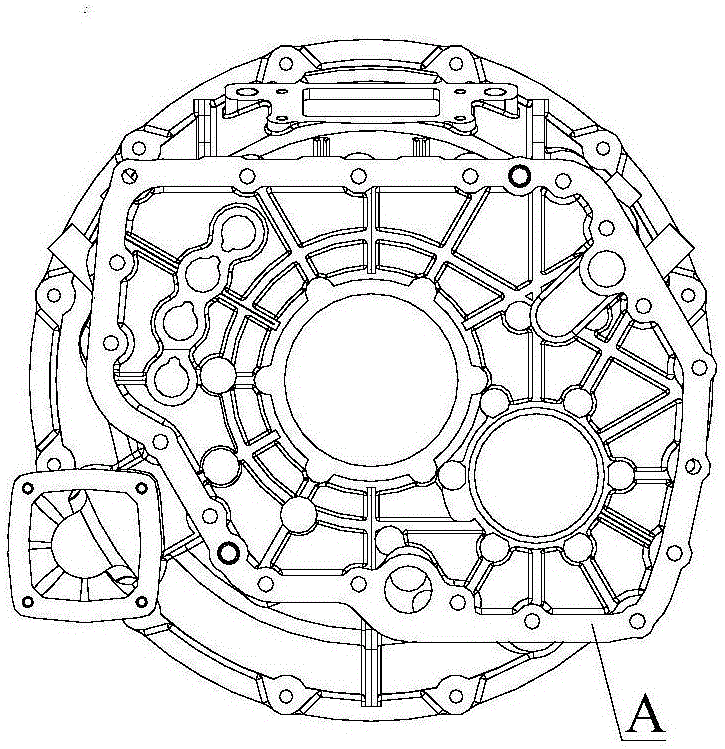

[0036] In order to better understand the present invention, the invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

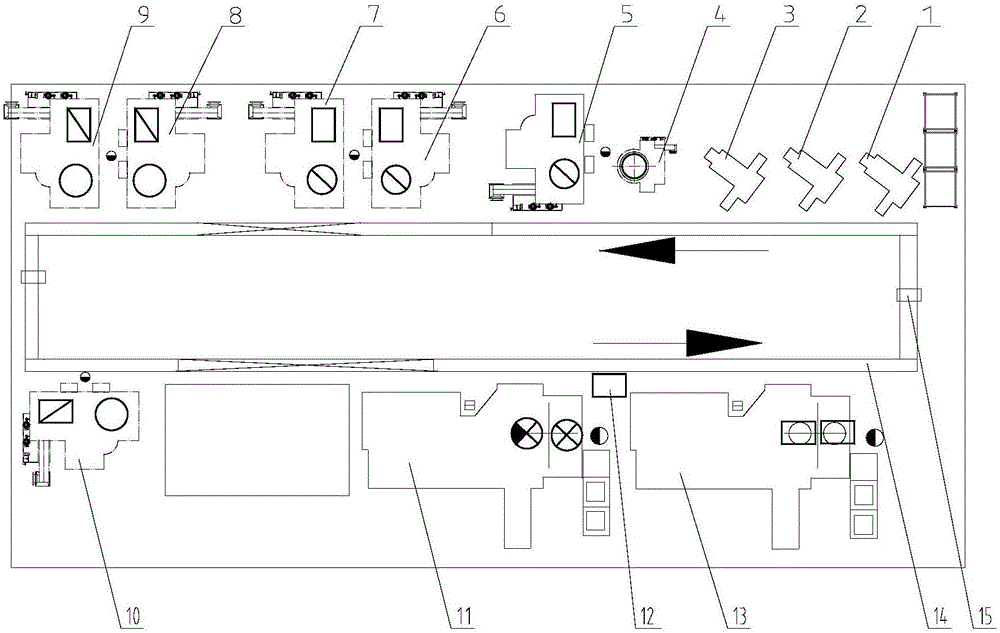

[0037] In order to solve the problems existing in the prior art, the present invention provides a mixed-flow production line for the front casing and the rear casing of the gearbox. Three vertical milling machines (the first vertical milling machine 1, the Two vertical milling machines 2, the third vertical milling machine 3), one CNC vertical lathe 4, six vertical machining centers (the first vertical machining center 5, the second vertical machining center 6, the third vertical machining Center 7, the fourth vertical machining center 8, the fifth vertical machining center 9, the sixth vertical machining center 10), a first horizontal machining center 11, a pneumatic marking machine 12 and a second horizontal Type machining center 13.

[0038] The center of the production line is provided with an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com