Method and system for improving heat exchange capacity of direct air cooling system

A technology of air-cooling system and heat exchange capacity, applied in lighting and heating equipment, steam/steam condensers, etc., can solve the problem of insufficient heat exchange capacity of air-cooling system, and achieve the effect of optimizing design temperature, reasonable construction investment, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

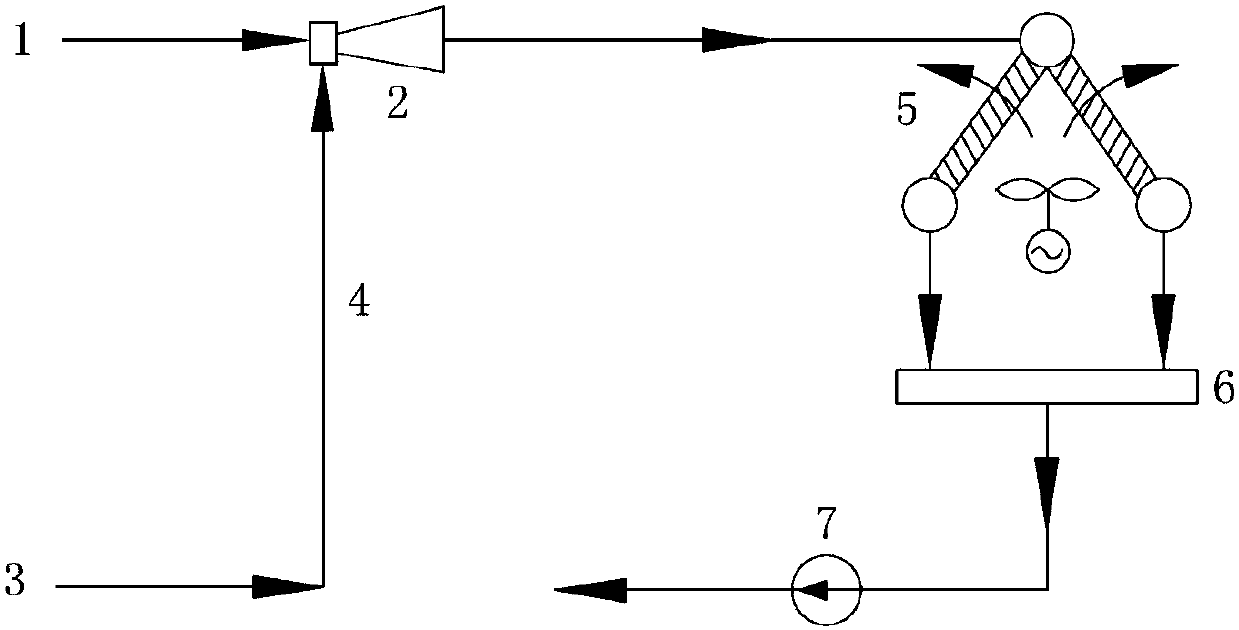

[0037] The direct air cooling system that has been put into operation is transformed to improve the heat exchange capacity of the original direct air cooling system, such as figure 1 In the process shown, the jet pump is installed at the proper position of the steam pipeline before the direct air cooling system. The high-temperature working fluid of the jet pump can be introduced from the thermal system of the unit or other heat sources. Considering the economy, the temperature of the high-temperature regulated steam is higher than that to be condensed The steam temperature is at least 200°C.

[0038] The high-temperature regulated steam (1) is injected as the working fluid through the nozzle of the jet pump (2), forming a vacuum in the mixing chamber of the jet pump (2), and the steam to be condensed (3) is sucked into the jet pump (2) through the steam pipeline (4) ) mixing chamber, the steam to be condensed (3) and the high-temperature regulated steam (1) are mixed in the m...

Embodiment 2

[0041] To build a new direct air-cooling system and improve the heat exchange capacity of the radiator of the direct air-cooling system, such as figure 1 In the process shown, the jet pump is installed at the proper position of the steam pipeline before the direct air cooling system. The high-temperature working fluid of the jet pump can be introduced from the thermal system of the unit or other heat sources. Considering the economy, the temperature of the high-temperature regulated steam is higher than that to be condensed The steam temperature is at least 200°C.

[0042] The high-temperature regulated steam (1) is injected as the working fluid through the nozzle of the jet pump (2), forming a vacuum in the mixing chamber of the jet pump (2), and the steam to be condensed (3) is sucked into the jet pump (2) through the steam pipeline (4) ) mixing chamber, the steam to be condensed (3) and the high-temperature regulated steam (1) are mixed in the mixing chamber of the jet pump...

Embodiment 3

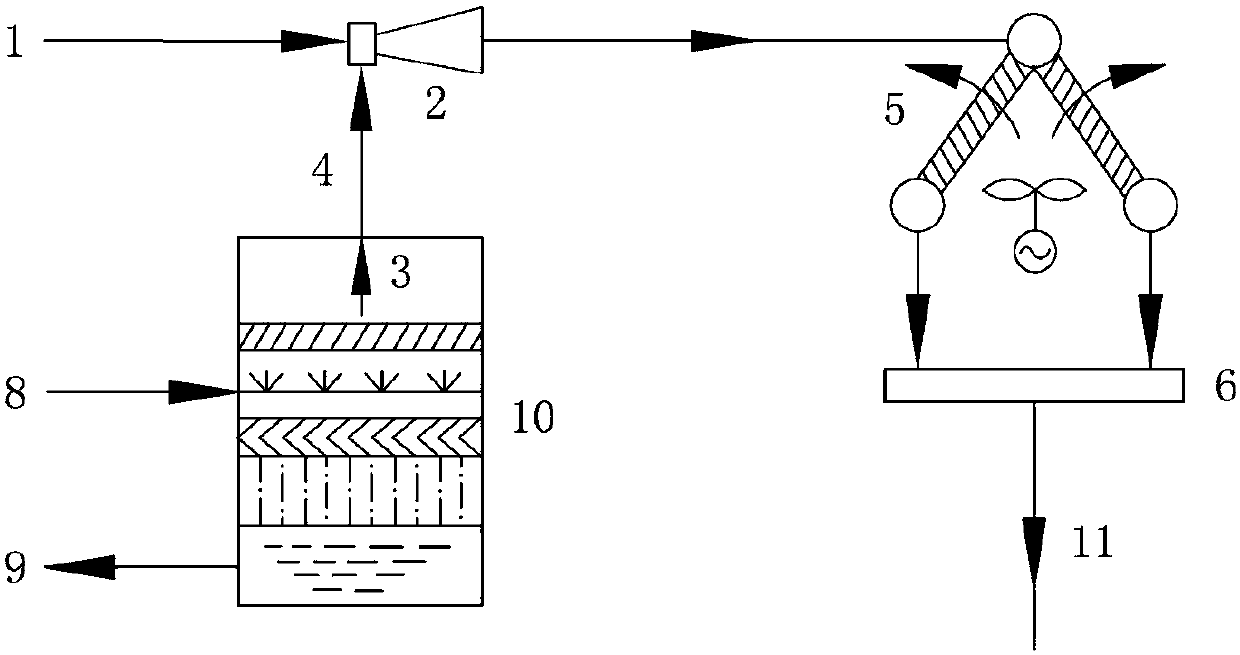

[0045] The wet cooling system is transformed into a cooling system that can recover cooling water vapor, using figure 2 In the process shown, the circulating water that absorbs heat from the circulating water system enters the negative pressure evaporation chamber (10) from the circulating water inlet (8) to evaporate to generate steam to be condensed (3), and the unevaporated circulating water is cooled by the circulating water outlet ( 9) Return to the circulating water system; the high-temperature regulated steam (1) is injected as a working fluid through the nozzle of the jet pump (2), and a vacuum is formed in the mixing chamber of the jet pump (2), and the steam to be condensed (3) passes through the steam pipeline (4 ) is sucked into the mixing chamber of the jet pump (2), the steam to be condensed (3) and the high-temperature regulated steam (1) are mixed in the mixing chamber of the jet pump (2) to form mixed steam, and the mixed steam passes through the diffusion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com