Engineering prefabricated main structure and supporting structure integration method based on open cut method

A technology of main structure and supporting structure, which is applied in the field of construction engineering and underground structure engineering. It can solve the problems that concrete does not meet the durability requirements, the construction quality is difficult to guarantee, and the application range is limited, so as to avoid difficult construction quality and improve durability. High performance and waterproof performance, strong self-waterproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

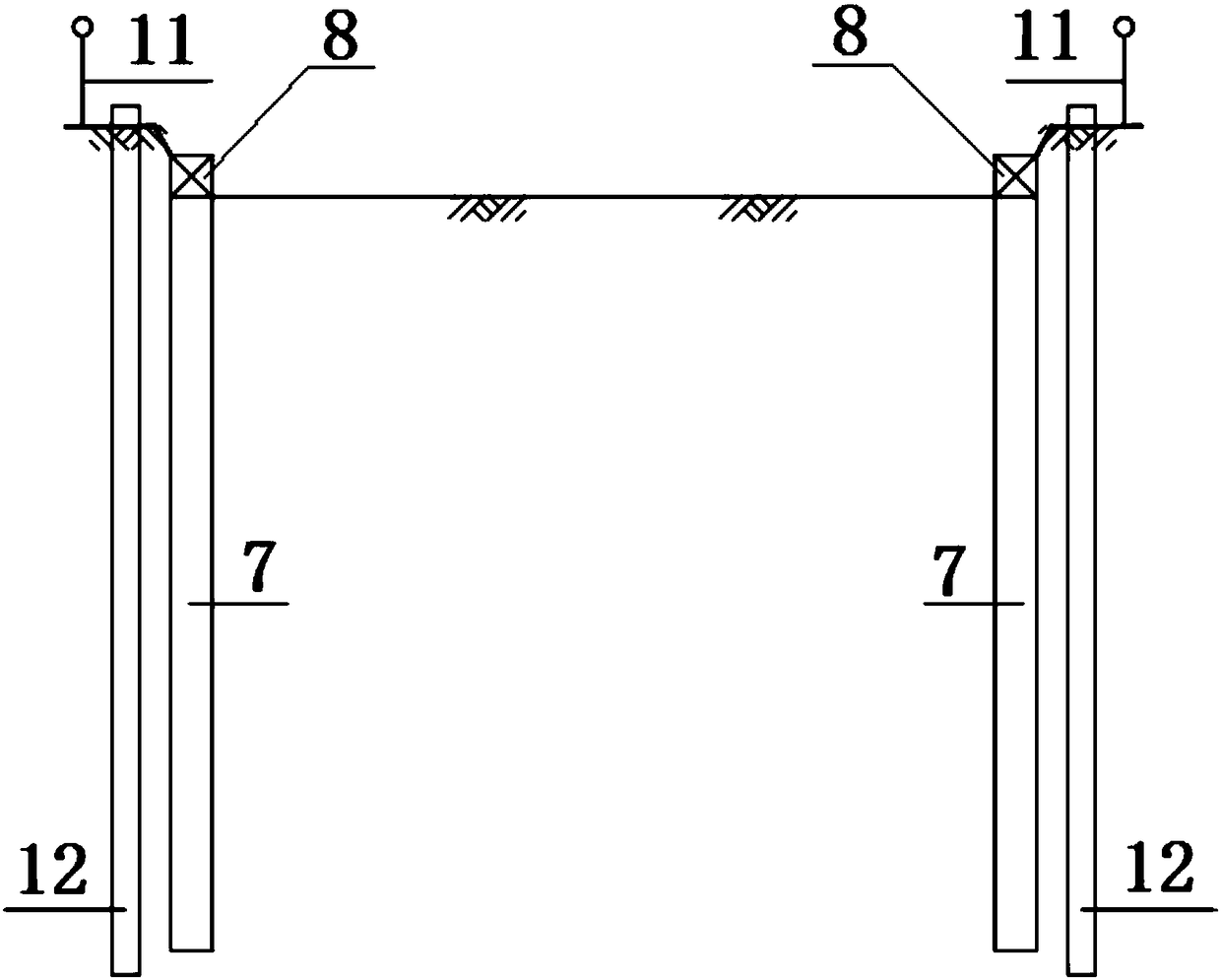

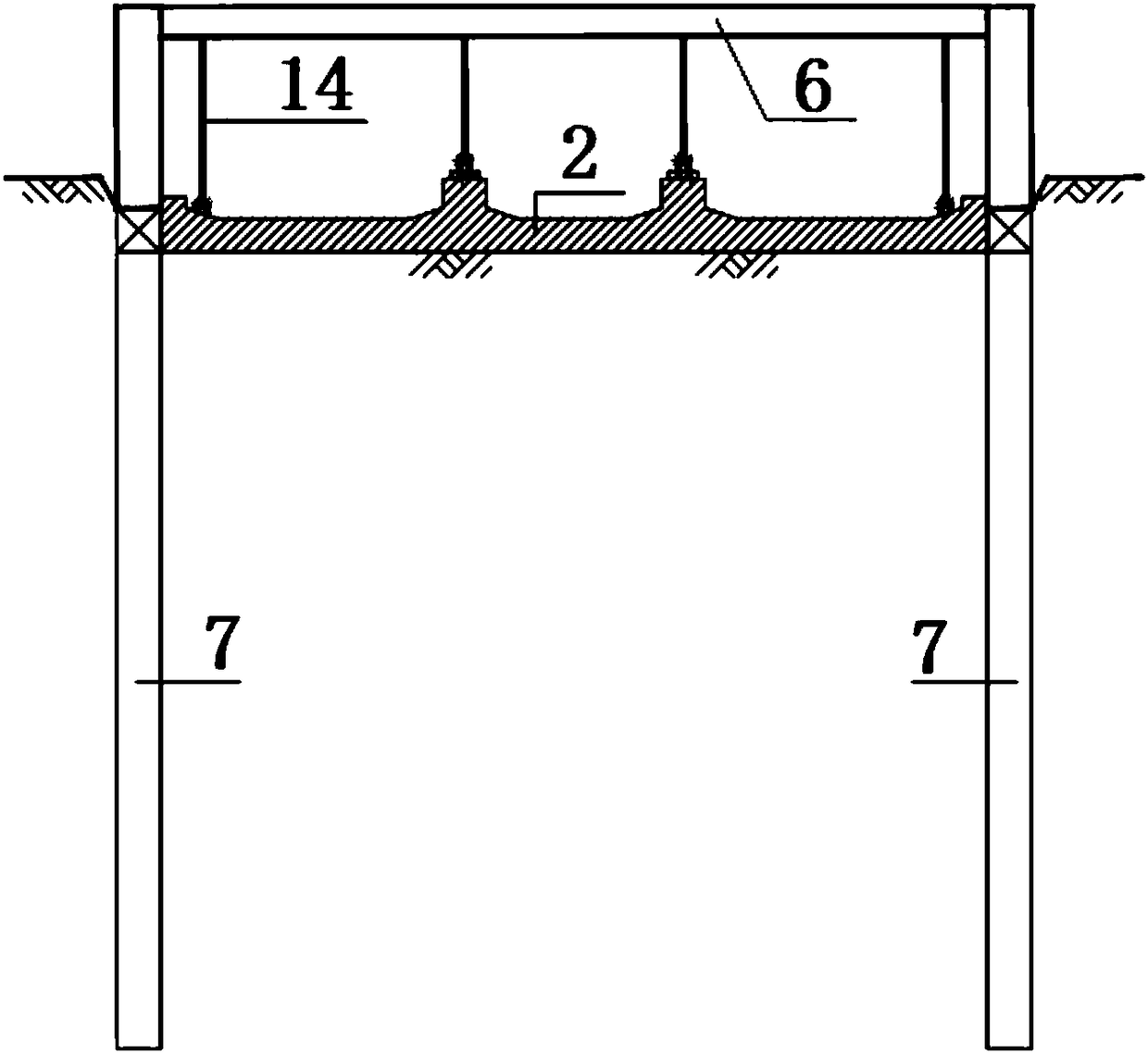

[0063] The method for integrating the main body structure and the support structure of the open cut method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0064] The method for integrating the main structure and supporting structure of the open-cut engineering prefabrication of the present invention includes the following steps.

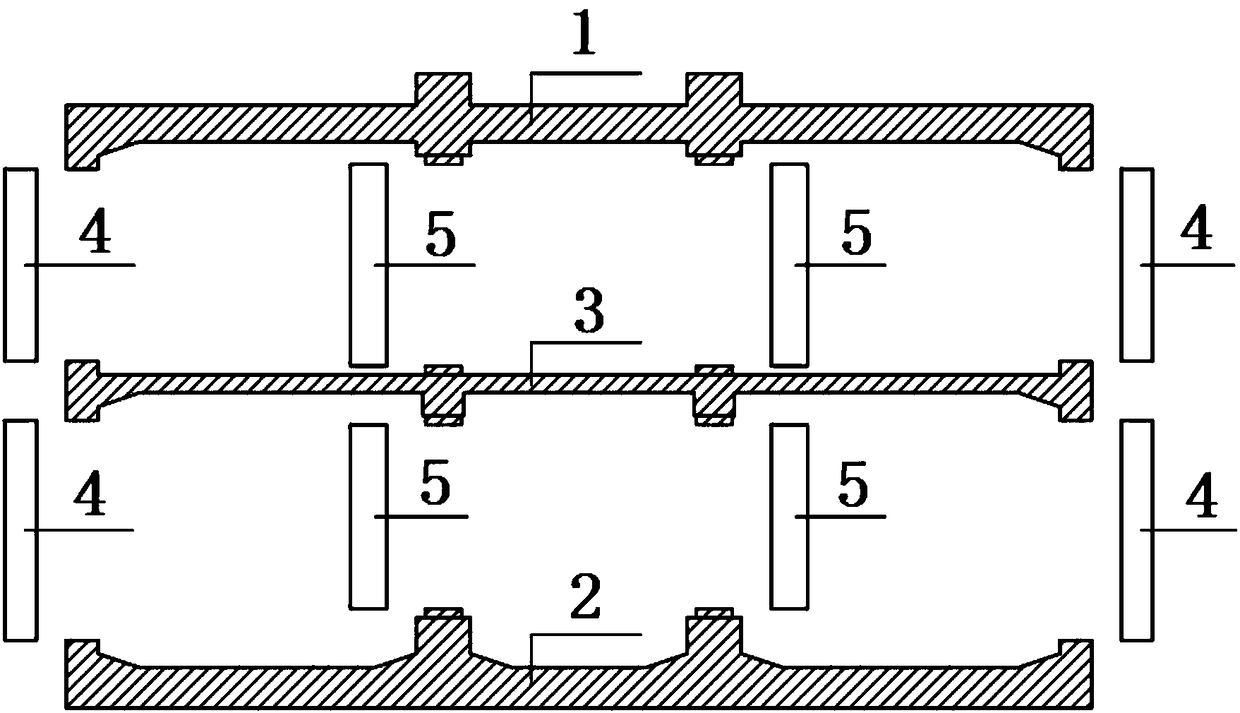

[0065] Step 1: Prefabricate the required prefabricated panels, the prefabricated panels include multi-component layered prefabricated panels, multiple side wall components 4 and multiple columnar components 5, the grouped prefabricated panels in this embodiment are made of floor prefabricated panels 2, the prefabricated panel 3 of the middle slab and the prefabricated panel 1 of the top slab. It should be noted that the longitudinal width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com