Production method of horizontal centrifugal rotary continuous casting metal billet and hollow continuous casting billet

A production method and technology of metal billets, applied in the field of machinery, can solve problems such as the quality of casting billets cannot meet the actual quality requirements, the perforation cost of the separation ring is fragile, and the limitation of seamless pipe production efficiency, so as to reduce the investment in infrastructure equipment, reduce Effects of investment in equipment and infrastructure, improvement of internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments in the embodiments will be described in detail below with reference to the accompanying drawings in the embodiment of the present invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

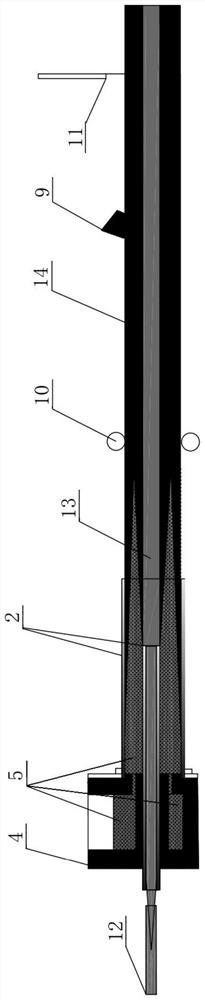

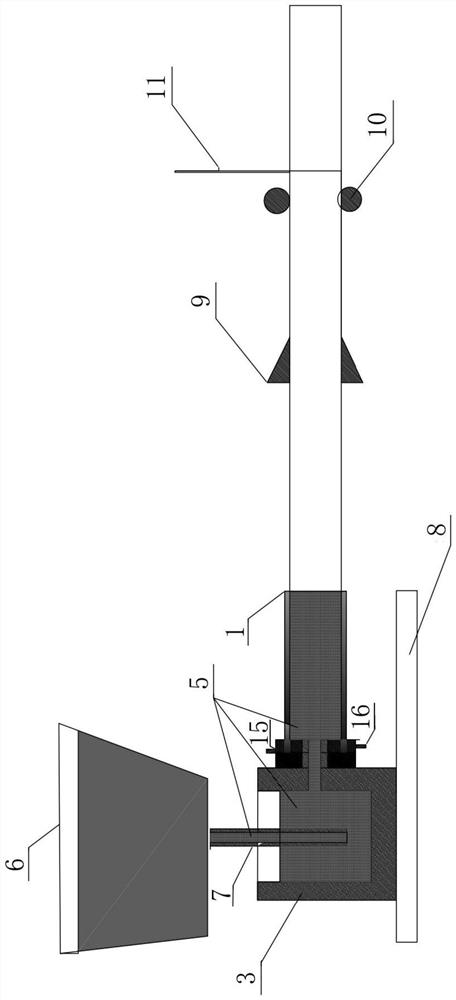

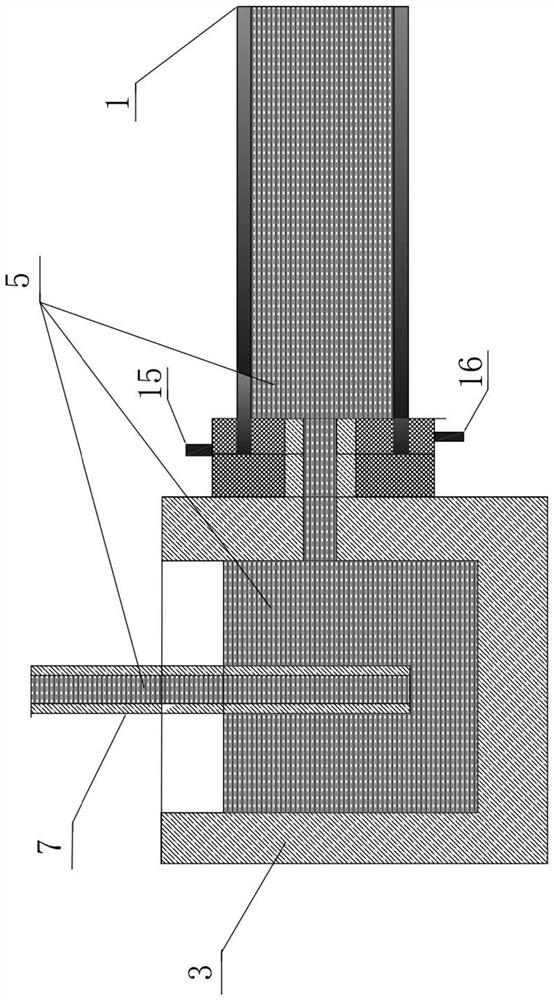

[0024] like Figure 1-3 As shown, a method of producing a horizontal centrifugal rotation coated metal blank and a hollow coil, including a crystallizer and a crystallizer, a crystallizer connected to the crystallizer, and the crystallizer adapter is mounted below the intermediate package 6, The crystallizer includes a solid-castry crystalline 1 and a hollow casting crystallizer 2 for producing a hollow cast blank, and the corresponding crystallizer adapter includes solid crystallizer adapter 3 and a hollow crystallizer adapter 4, a crystallizer Both the adapter and the crystallizer are mounted on the horizontal sliding shocking shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com