Direct reduction process for producing sponge iron by using coke oven gas

A technology of coke oven gas and sponge iron, which is applied to the improvement of process efficiency, furnace, shaft furnace and other directions to achieve the effect of increasing H2 content, reducing energy consumption and reducing heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

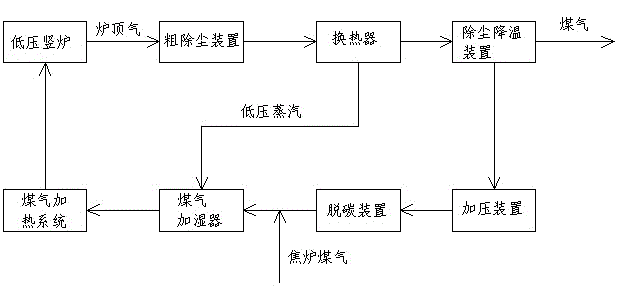

[0031] figure 1 It is a process flow chart of the process of the present invention.

[0032] As shown in the figure, a direct reduction process for the production of sponge iron from coke oven gas in the present embodiment is characterized in that it comprises the following steps:

[0033] a. Input the purified and pressurized coke oven gas into the gas humidifier for humidification,

[0034] b. Input the humidified coke oven gas into the gas heating system for heating,

[0035] c. Input the heated coke oven gas into the low-pressure shaft furnace to reduce iron ore and generate shaft furnace top gas.

[0036] This process utilizes the fresh sponge iron reduced in the low-pressure shaft furnace for CH 4 with CO 2 、H 2 Catalysis of O conversion reactions, and utilization of sponge iron and CH 4 The carburizing reaction makes the CH in the coke oven gas 4 Conversion and upgrading in the shaft furnace to generate CO and H 2 , to replenish the reducing gas lost in the redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com