Rich oxygen supply system of dry rotary kiln cement production

A dry-process rotary kiln and supply system technology, which is applied in the direction of combustion air/fuel supply, combustion method, indirect carbon dioxide emission reduction, etc., can solve the problem that it is difficult to achieve full mixing of oxygen-enriched and original pipe air, difficult to ensure operational stability, Increase investment and operating costs and other issues to achieve the effects of reducing energy consumption for preparation, ensuring high stability, and reducing equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

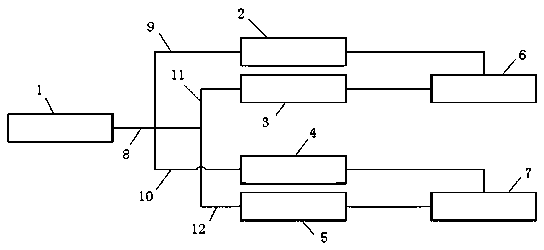

[0024] An oxygen-enriched supply system for dry-process rotary kiln cement production, comprising a VPSA oxygen production unit 1, a coal air blower, a pulverized coal burner, and a clean air blower; the VPSA oxygen production unit 1 is connected to a main pipeline 8, and the The main pipeline 8 is provided with a branch pipeline one 9 and a branch pipeline two 10 respectively connected to the coal air fan suction ports of the rotary kiln and the calciner, and the coal air fans of the rotary kiln and the calciner are respectively connected to respective pulverized coal burners; The main pipeline 8 is provided with a branch pipeline three 11 and a branch pipeline four 12 respectively connected to the suction ports of the clean air fans of the rotary kiln and the calciner, and the clean wind fans of the rotary kiln and the calciner are respectively connected to respective pulverized coal burner.

Embodiment 2

[0026] An oxygen-enriched supply system for dry-process rotary kiln cement production, comprising a VPSA oxygen production unit 1, a coal air blower, a pulverized coal burner, and a clean air blower; the VPSA oxygen production unit 1 is connected to a main pipeline 8, and the The main pipeline 8 is provided with a branch pipeline one 9 and a branch pipeline two 10 respectively connected to the coal air fan suction ports of the rotary kiln and the calciner, and the coal air fans of the rotary kiln and the calciner are respectively connected to respective pulverized coal burners; The main pipeline 8 is provided with a branch pipeline three 11 and a branch pipeline four 12 respectively connected to the suction ports of the clean air fans of the rotary kiln and the calciner, and the clean wind fans of the rotary kiln and the calciner are respectively connected to respective pulverized coal burner.

[0027] The front of the VPSA oxygen generating unit is connected to an air cooler,...

Embodiment 3

[0029] An oxygen-enriched supply system for dry-process rotary kiln cement production, comprising a VPSA oxygen production unit 1, a coal air blower, a multi-channel pulverized coal burner, and a clean air blower; the VPSA oxygen production unit 1 is connected to a main pipeline 8, The main pipeline 8 is provided with a branch pipeline one 9 and a branch pipeline two 10 respectively connected to the coal air blower inlets of the rotary kiln and the calciner, and the coal air blowers of the rotary kiln and the calciner are respectively connected to the multi-wind blower respectively. Road pulverized coal burner; said main pipeline 8 is provided with branch pipe 3 11 and branch pipe 4 12 respectively connected to the suction port of the clean air blower of the rotary kiln and the calciner, and the clean wind blower of the rotary kiln and the calciner is in turn Connect the respective multi-channel pulverized coal burners.

[0030] The front of the VPSA oxygen generating unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com