Manufacturing method of glucose

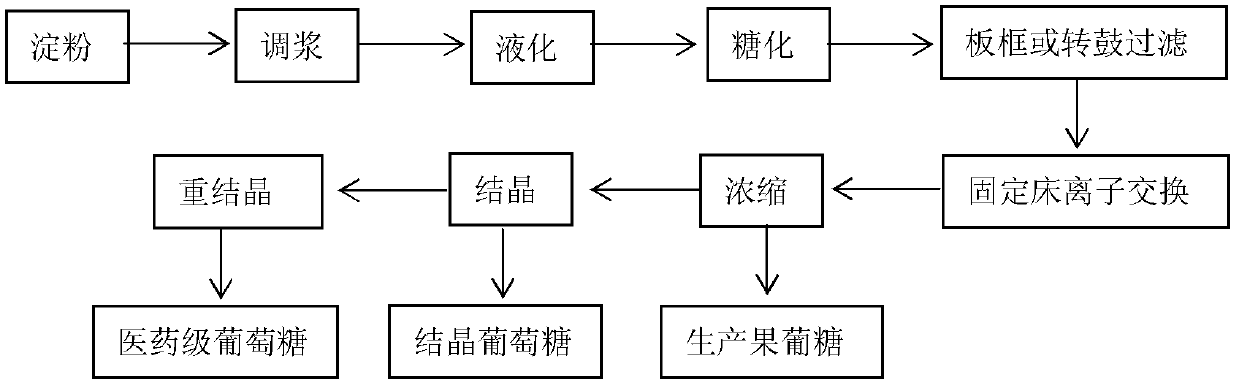

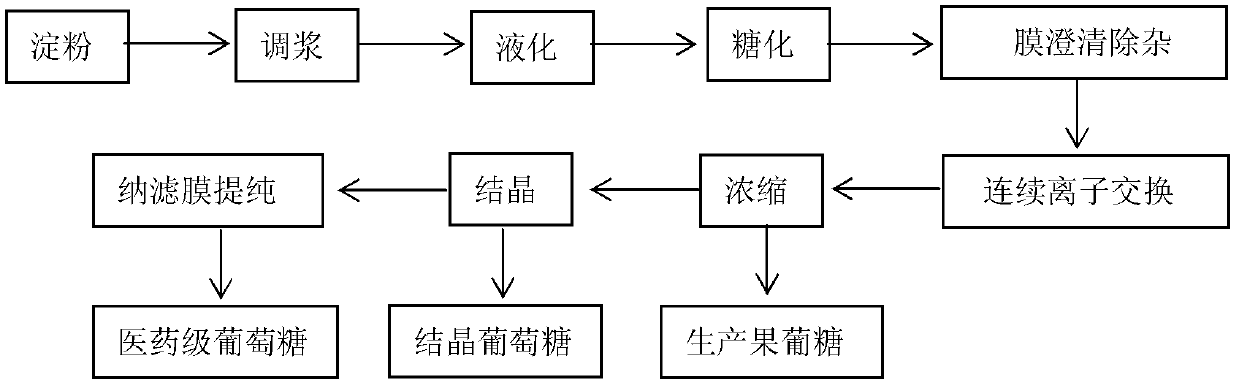

A manufacturing method, glucose technology, applied in the field of biochemistry, can solve the problems of poor removal of impurities, reduced service life of resin, low product quality and yield, and achieve the effect of improving utilization rate, prolonging service life and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 obtains saccharification liquid (prior art)

[0037]Starch liquefaction: Mix starch and water to prepare a liquid starch emulsion for glucose production. The content of starch accounts for 20%-35% of the total mass of the liquid starch emulsion, and then sterilize to prepare a starch emulsion, and then to the starch emulsion Add high-temperature amylase to the water, spray it once with high pressure from the liquefaction injector, add enzyme twice for continuous liquefaction reaction, and hydrolyze it into a liquefied starch solution with a glucose value between 14% and 25%;

[0038] Saccharification: Cool the liquefied starch solution with a glucose value between 14% and 25% prepared in the previous steps to 35-45°C, then add compound glucoamylase and enzymatically hydrolyze it into a glucose saccharification solution at this temperature. The saccharification solution is stored at a height of about 7.5m and a volume of 120m 3 In the saccharification tank,...

Embodiment 2

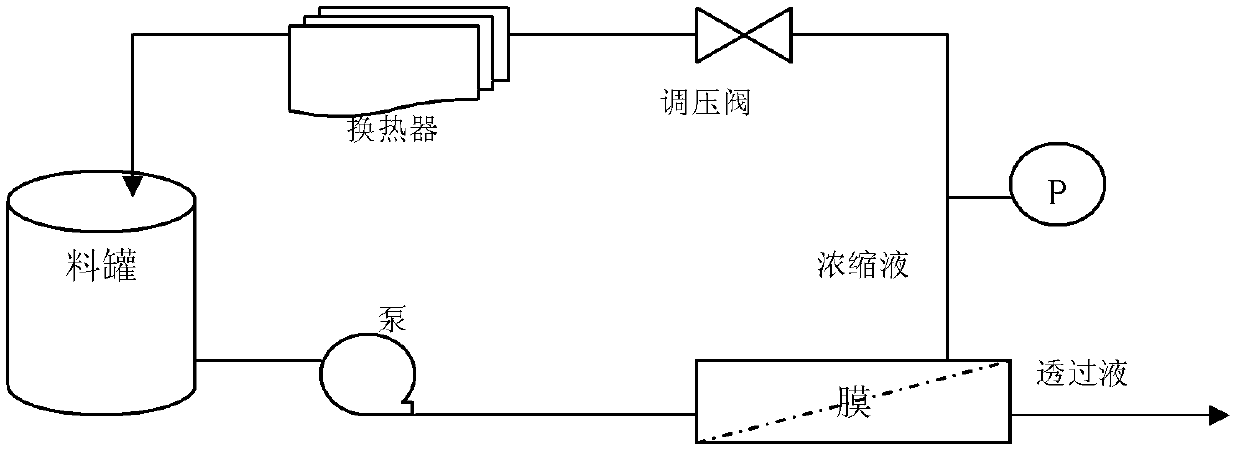

[0040] One of embodiment 2 membrane filtration impurity removal

[0041] In this embodiment, Asahi Kasei hollow membrane UMP-153 is used as the microfiltration membrane. The inner diameter of the UMP-153 membrane filament is 2.6mm and the pore diameter is 0.2um. It can be seen from Table 1 that under the operating condition of the inlet pressure of 2.4bar, the concentration is 5-7 times, the membrane basically has no interception of the product, and the flux is maintained between 130LMH-210LMH, and combined image 3 It can be seen that the membrane operation is very stable.

[0042] Table 1 UMP-153 membrane operating data

[0043] the batch

Embodiment 3

[0044] Embodiment 3 Membrane filtration impurity removal

[0045] In this embodiment, Asahi Kasei hollow membrane USP-143 is used as the microfiltration membrane. The inner diameter of the USP-143 membrane filament is 1.4mm and the pore diameter is 0.1um. From the membrane operation data in Table 2, it can be seen that under the operating conditions of an average inlet pressure of about 1.4bar, an average outlet pressure of about 1.1bar, and a circulation flow rate of 1600-2000m3 / h and a temperature of 42-62°C, the concentration to About 6 times, there is basically no interception in the glucose production process, and the membrane flux is between 150-160LMH; combined with the membrane flux change curve, the membrane flux fluctuates between 160LMH, and the repeatability of the three batches is good , indicating that the membrane is very stable in operation; in addition, it can be seen from the test data of the filtrate in Table 5 that in the case of a high liquid-solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com