Integral process and equipment of garbage fuel synthesis and burning generation

A technology for incinerating power generation and waste fuel, which is applied in the field of integrated processes and equipment for the synthesis of waste fuel and high-efficiency waste incineration and power generation, can solve problems such as high production costs, and achieve the effects of saving operating costs, reducing emissions, and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

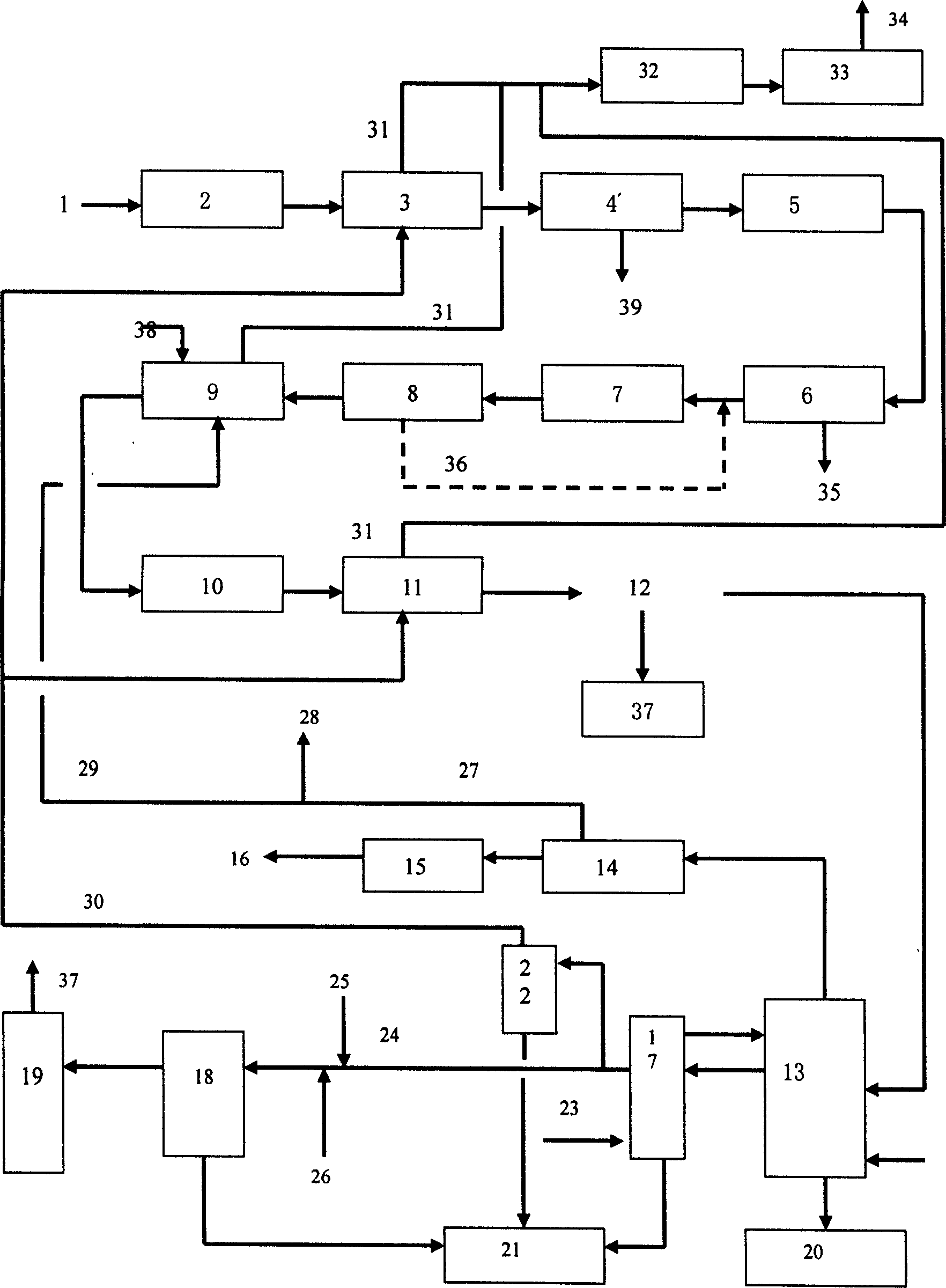

[0018] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments. The waste fuel synthesis and incineration power generation integration process of the present invention consists of two processes of waste-derived fuel synthesis and combustion power generation, wherein the waste-derived fuel synthesis includes at least one crushing, drying, magnetic separation, extrusion molding after tempering and mixing The resulting refuse-derived fuel is fed into the boiler for combustion and power generation; the above-mentioned refuse-derived fuel (RDF) synthesis process and RDF incineration power generation process are two organically combined operating unit steps of a continuous process.

[0019] At least one drying in the garbage-derived fuel synthesis process is hot air drying. It uses waste flue gas at the outlet of the waste-derived fuel combustion boiler as a heat source for hot air drying. The hot air required for the dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com