Municipal refuse treatment device and method

A municipal waste and treatment device technology, which is applied in the field of waste recycling, can solve problems such as lower calorific value, high energy consumption, and deterioration of combustion characteristics, and achieve the effects of reducing heat load, reducing COD, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

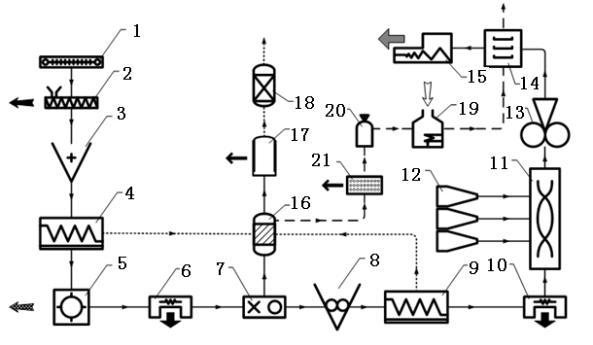

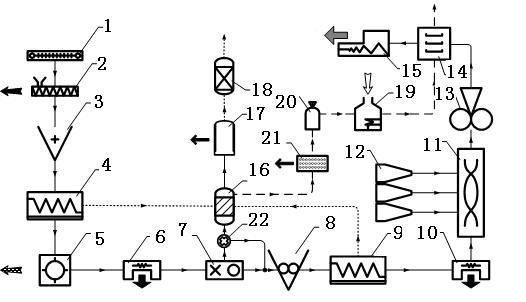

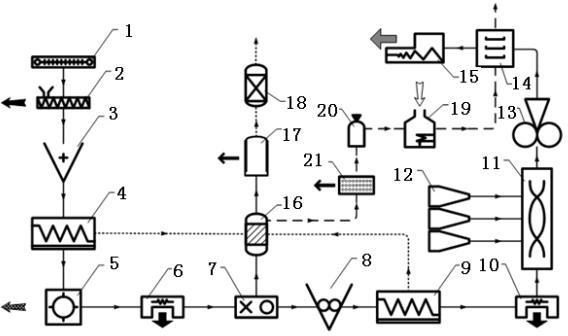

[0039] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0040] seefigure 1 Shown, a kind of municipal waste disposal device comprises feeder 1, screening machine 7, mixer 11, RDF molding machine 13, drier 14, RDF packing machine 15, anaerobic generator 16 and biogas boiler 19, described feeding Between the discharge port of the material machine 1 and the feed port of the RDF subpacker 15, the primary separator 2, the coarse crusher 3, the primary dehydrator 4, the winnowing machine 5, and a The primary metal separator 6, the screening machine 7, the fine crusher 8, the secondary dehydrator 9, the secondary metal separator 10, the mixer 11, the RDF forming machine 13 and the dryer 14; The organic material discharge port of the screening machine 7 is connected with the feed port of the anaerobic generator 16 through a pipeline, and the discharge port of the anaerobic generator 16 is connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com