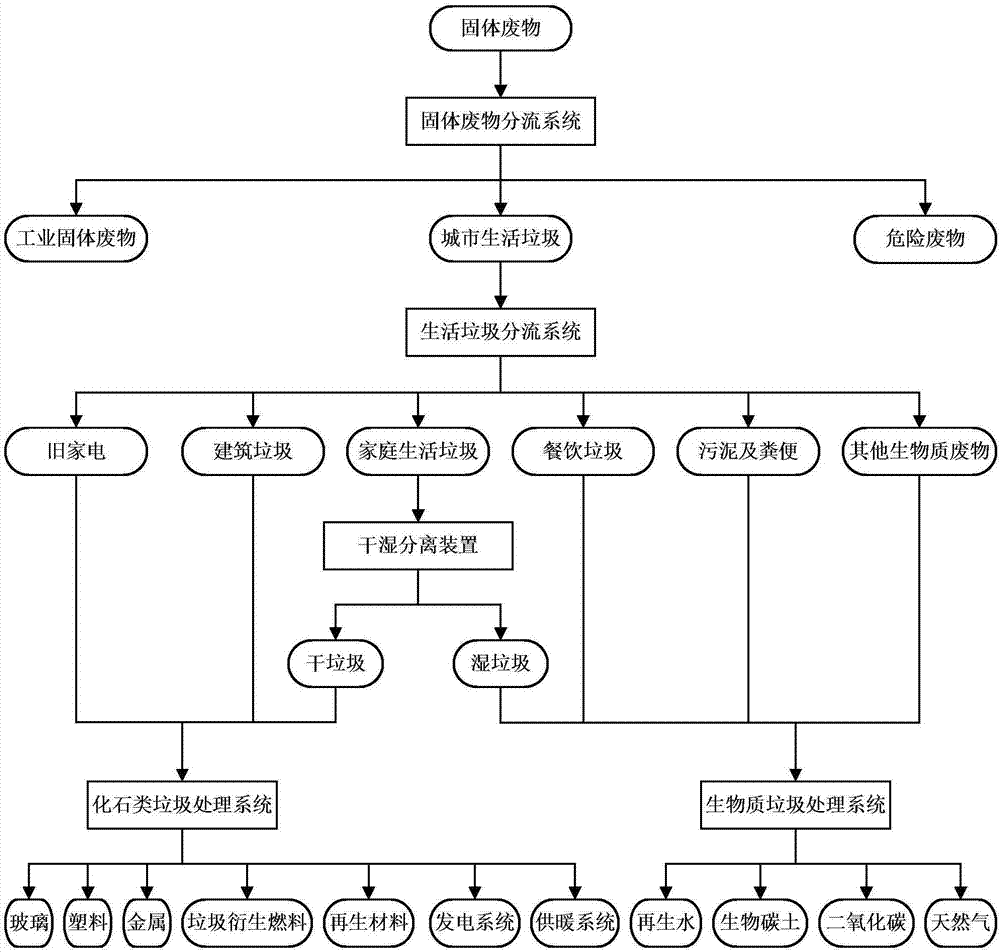

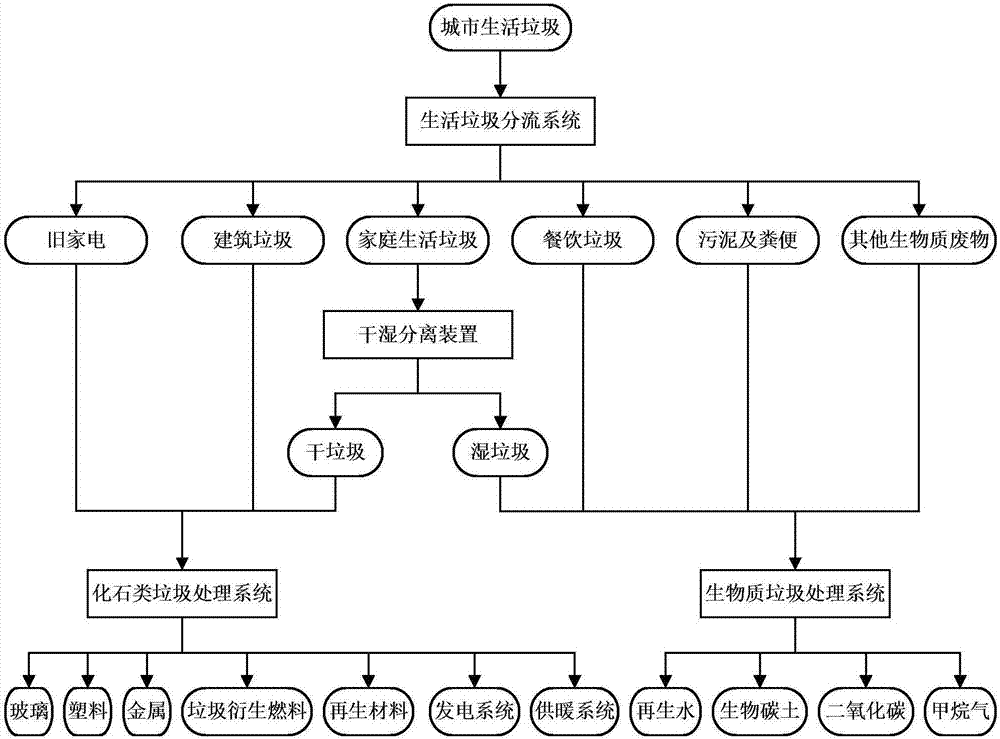

Urban venous industrial park and construction method as well as solid waste processing system and method

A technology of waste treatment system and industrial park, applied in waste treatment, solid waste removal, biomass post-treatment, etc., can solve the problem of lack of systematic thinking and optimal technical route of treatment and resource utilization, and achieve energy balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

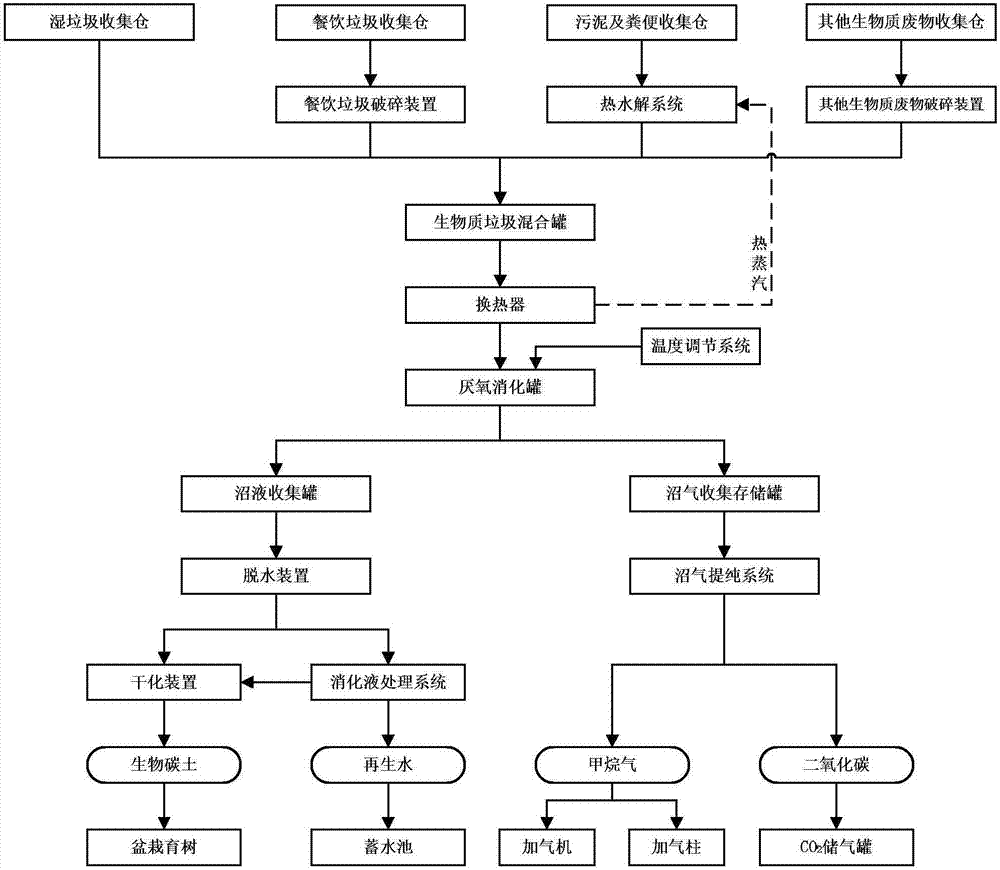

Examples

example 1

[0152] 1) Pot selection: select pots with a diameter of 60cm or 60cm.

[0153] 2) Soil loading: 80% of biochar soil, 10% of sandy soil and 10% of crushed straw are stirred evenly, and then naturally loaded. Adjust the pH of the soil to 6.

[0154] 3) Water adjustment: the moisture content of the cultivation soil is controlled at about 20%.

[0155] 4) Draining salt: Since the salt content of the mixed cultivation soil in this embodiment is too high (leach solution TDS3000mg / l), it is necessary to drain the salt with water. With 100kPa water pressure and 15L / H water flow, keep for 20 minutes, 5 times, 10 hours between each time.

[0156] 5) Stabilization: Since the proportion of sludge production used in this embodiment exceeds 50%, a slight blast is required to speed up the process of decomposing and stabilizing. The blast working pressure is 700 mm water column, the air flow rate is 60L / H, for 10 consecutive days, each time for 1 hour, with an interval of 4 hours.

[0157...

example 2

[0162] 1) Pot selection: select pots with a diameter of 40cm or 40cm.

[0163] 2) Soil loading: 30% of biochar soil, 10% of cultivated soil, 50% of sandy soil and 10% of crushed straw, mixed evenly, and then loaded naturally. Adjust the pH of the soil to 7.

[0164] 3) Water adjustment: the moisture content of the cultivation soil is controlled at about 20%.

[0165] 4) Plant rose seedlings.

[0166] 5) Maintenance: In summer, the working water pressure of micro-irrigation is 50-100kPa, and the water flow rate is 10-15L / H, with an interval of 5-7 days, 1-2 times a day, 0.5 hours each time; in winter, the working water pressure of micro-irrigation is 50kPa, The water flow rate is 10L / H, and the interval is 10-15 days, once a day, 0.5 hours each time. However, it must be noted that once the phenomenon of yellow leaves occurs, the temperature of the cultivation soil must be measured in time. If it is too high, the micro-blast system and micro-irrigation system need to be turne...

example 3

[0170] 1) Pot selection: select pots with a diameter of 60cm or 60cm.

[0171] 2) Soil loading: 50% of biochar soil, 40% of sandy soil and 10% of crushed straw are stirred evenly, and then naturally loaded. Adjust the pH of the soil to 8.

[0172] 3) Water adjustment: the moisture content of the cultivation soil is controlled at about 20%.

[0173] 4) Stabilization: Since the proportion of sludge production used in this embodiment exceeds 50%, a slight blast is required to speed up the process of decomposing and stabilizing. The blast working wind pressure is 700 mm water column, the air flow is 60L / H, for 5 consecutive days, each time for 1 hour, with an interval of 4 hours.

[0174] 5) plant Albizia juliensis seedlings.

[0175] 6) Maintenance: In summer, the working water pressure of micro-irrigation is 100-150kPa, the water flow rate is 15-20L / H, the interval is 5-7 days, 1-2 times a day, 0.5-1 hour each time. The working water pressure of micro-irrigation in winter is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com