Recycling method of combustible solid waste

A technology of solid waste and treatment method, applied in the field of reuse and treatment of combustible solid waste, can solve the problems of high cost, large investment in incineration equipment, environmental pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

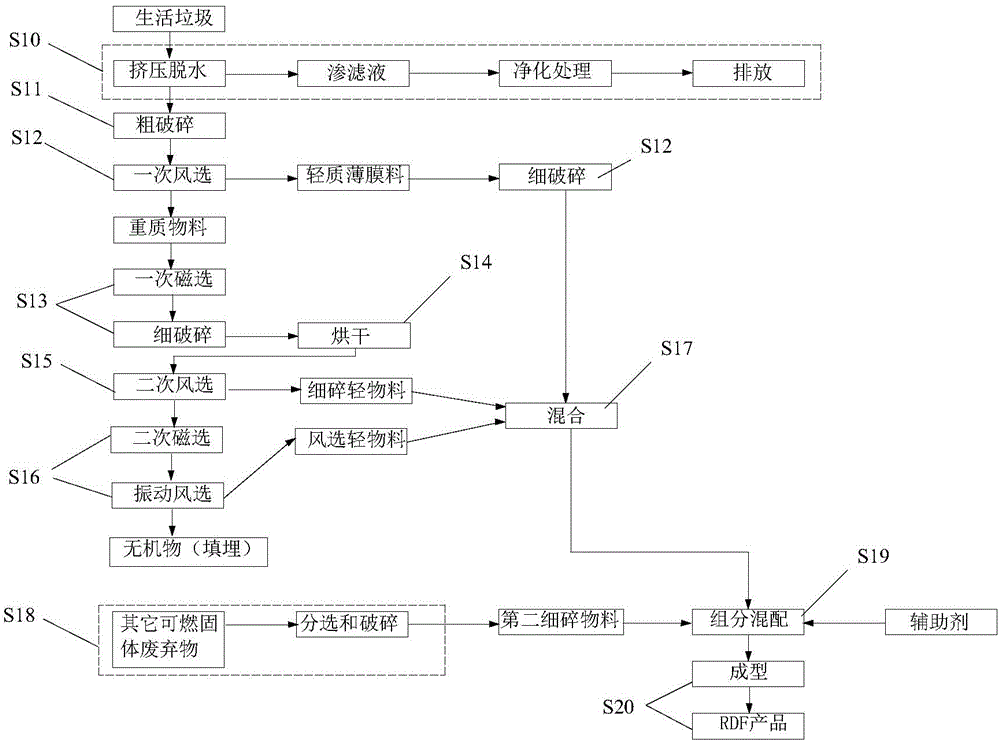

[0028] S10: Squeeze and dehydrate domestic waste: Squeeze domestic waste with extrusion equipment to reduce its water content to about 40%, and the extruded leachate will be treated and discharged after reaching the standard;

[0029] S11: Coarsely crush the domestic waste after the leachate is removed by squeezing, for example, into fragments with a particle size of less than 120mm;

[0030] S12: Carry out wind force coarse sorting (primary winnowing) to the coarsely crushed domestic waste, and divide it into light film material (i.e. the first light object) and heavy material (i.e. the first heaviest object); Fragments with a particle size of less than 20mm;

[0031] S13: Carry out fine crushing after a magnetic separation of heavy materials, and crush them into fragments with a particle size of less than 20mm;

[0032] S14: Dry the finely crushed heavy materials, and control the moisture content to less than 20%;

[0033] S15: performing secondary winnowing on the dried h...

Embodiment 2

[0041] S10: Squeeze and dehydrate domestic waste: Squeeze domestic waste with extrusion equipment to reduce its water content to about 40%, and the extruded leachate will be treated and discharged after reaching the standard;

[0042] S11: Coarsely crush the domestic waste after the leachate is removed by squeezing, for example, into fragments with a particle size of less than 120mm;

[0043] S12: Carry out rough wind separation (primary winnowing) to the coarsely crushed domestic waste, and divide it into light film materials and heavy materials; finely crush the light film materials into fragments with a particle size of less than 20mm;

[0044] S13: Carry out fine crushing after a magnetic separation of heavy materials, and crush them into fragments with a particle size of less than 20mm;

[0045] S14: Dry the finely crushed heavy materials, and control the moisture content to less than 20%;

[0046] S15: Perform secondary winnowing on the dried heavy materials to obtain f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com