Method for performing pyrolysis uniting building-material utilization to rubbish oversize products

A technology for oversize and garbage, which is applied in the field of pyrolysis and combined building materials utilization for garbage oversize, can solve the problems of inability to continuously feed materials, incomplete utilization, unstable operation, etc., so as to improve incineration performance and prevent odor. The effect of exhausting air and increasing calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

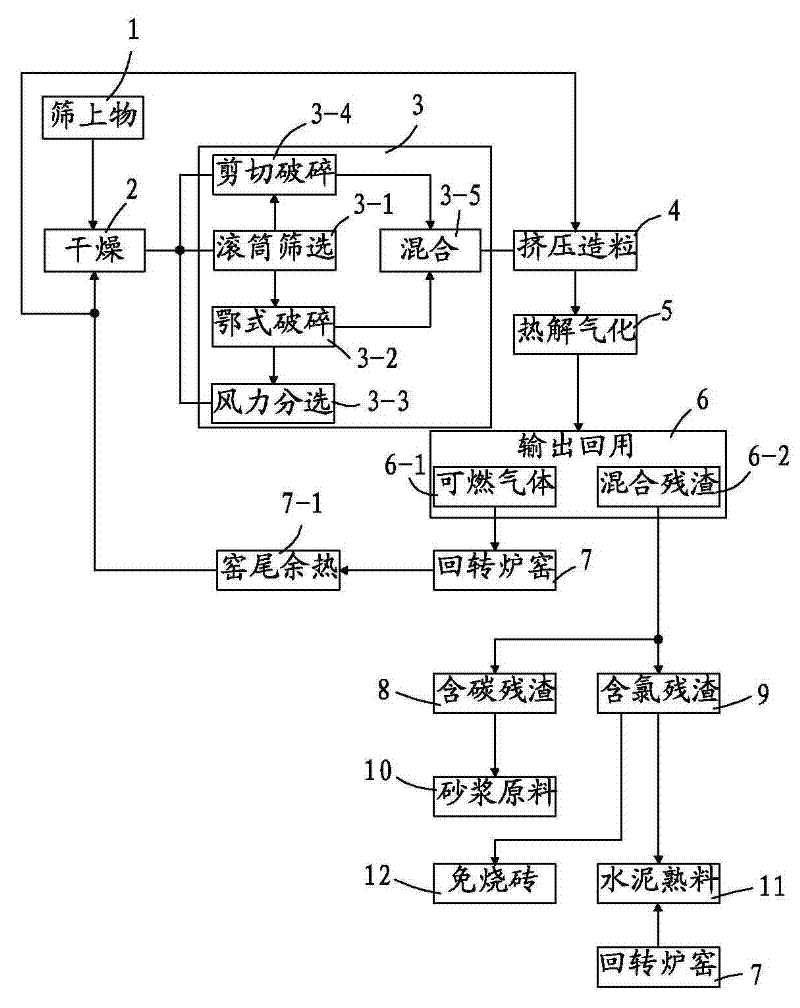

[0023] An embodiment of a method for pyrolyzing combined building materials utilization for garbage oversize, firstly, the garbage undersize with a particle size of less than 15mm is sent to a garbage composting plant for composting or to a garbage landfill as covering soil, or sent to a cement rotary Cement clinker is obtained by burning in the kiln; for the treatment process sequence of the garbage oversize > 15mm, please refer to figure 1 : Oversize 1→drying 2→screening, crushing, winnowing, mixing 3→extrusion granulation 4→pyrolysis and gasification 5→output recycling 6:

[0024] Drying: use the waste heat 7-1 at the kiln tail of the cement rotary kiln 7 at about 140°C to dry the waste on the sieve for 3-5 hours to reduce the moisture content to 10-15% to obtain dry waste;

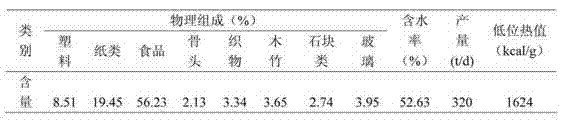

[0025] Screening, crushing, winnowing, and mixing: the drum screening 3-1 is used, and the dry garbage is divided into three parts according to the particle size: 60mm, of which: the 60mm garbage, sen...

Embodiment 2

[0031] Referring to embodiment 1, the present embodiment is a further preferred example of the content of embodiment 1, therefore, the method further has, the amount of quicklime added is 8%-12% of the garbage weight, and the added dewatered sewage Mud or coal powder is 20% to 30% of the weight of the garbage.

Embodiment 3

[0033] Referring to embodiment 2, this embodiment is a further preferred example of the content of embodiment 2. Therefore, the method further has, the amount of quicklime added is 10% of the garbage weight, and the dewatered sludge or coal added is Powder is 15% of the weight of the garbage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com