Garbage derived fuel and preparation method thereof

A technology for waste-derived fuel and domestic waste, applied in biofuels, fuels, waste fuels, etc., can solve the problems of low calorific value of combustible gas, serious secondary pollution, etc., to improve energy density, reduce pollution, and inhibit dioxins. The effect of substance-like generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] Its preferred embodiment of the refuse-derived fuel of the present invention comprises the following raw materials:

[0021] Domestic garbage 70-90 parts, can be 70, 75, 80, 85, 90 parts, etc.;

[0022] 10-30 parts of coal, can be 10, 15, 20, 25, 30 parts, etc.;

[0023] Calcium-containing substances 0.1-1 part, can be 0.1, 0.3, 0.5, 0.7, 1 part, etc.

[0024] The components of the above raw materials are parts by weight.

[0025] According to needs, the garbage-derived fuel can be in the form of pellets, blocks or honeycombs.

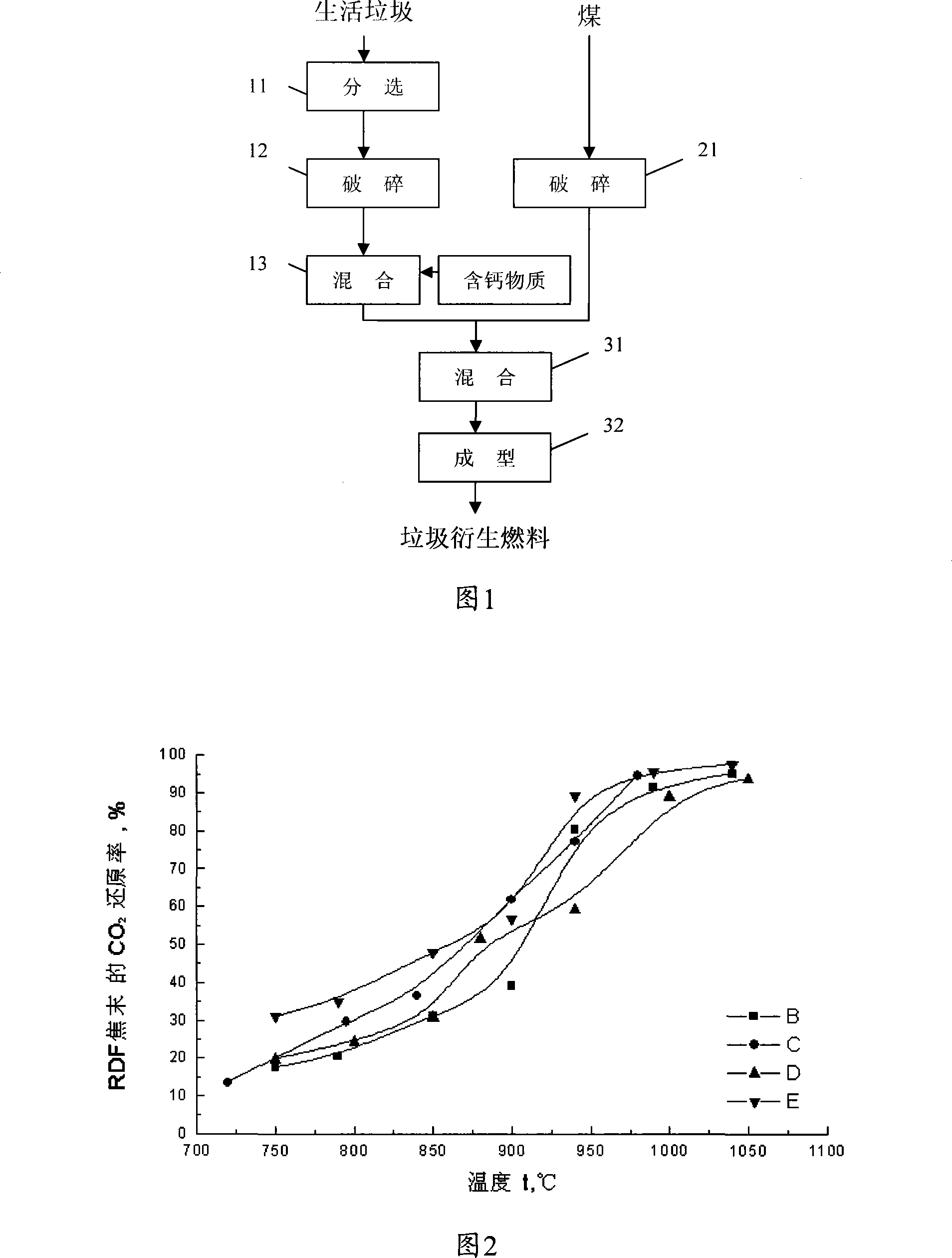

[0026] Its preferred embodiment of the preparation method of garbage derived fuel of the present invention is,

[0027] Using MSW as raw material, it is sorted, crushed, mixed, and by adding calcium-containing substances and coal powder, uniformly mixed and formed, and finally solid RDF is obtained. The RDF prepared by the invention is suitable for use in combustion, pyrolysis and gasification, and realizes efficient and clean energy utiliza...

specific Embodiment 1

[0036] The garbage-derived fuel is composed of the following components by weight: 89.5 parts by weight of pulverized domestic garbage, 10 parts by weight of coal powder, and 0.5 parts by weight of calcium-containing substances. The above-mentioned raw materials are sent to the mixer for mixing and mixing, and then sent to the double-roll forming machine, and finally processed into egg-shaped dense RDF with a particle size of 25mm.

[0037] After testing, the calorific value Q of the prepared garbage-derived fuel net , ad is 9716.3kJ / kg, which is 30% higher than that of MSW; the bulk density is obviously increased to 2360kg / m 3 , is 5.5 times that of MSW; under the molding pressure of 15MPa, the cold strength exceeds 66%, which is higher than the strength of MSW under the same pressure (59%), and the hot strength TS +6 and TS +3 5% and 20%, respectively, which are lower than the strength of MSW under the same pressure (11% and 31%); the crucible expansion number is about 1, ...

specific Embodiment 2

[0039] The garbage-derived fuel is composed of the following components by weight: 79.5 parts by weight of pulverized domestic garbage, 20 parts by weight of coal powder, and 0.5 parts by weight of calcium-containing substances. The above-mentioned raw materials are sent to the mixer for mixing and mixing, and then sent to the double-roll forming machine, and finally processed into egg-shaped dense RDF with a particle size of 25mm.

[0040] After testing, the calorific value Q of the prepared garbage-derived fuel net , ad is 11960.2kJ / kg, which is 60% higher than that of MSW; the bulk density is obviously increased to 2360kg / m 3 , is 5.5 times that of MSW; under the molding pressure of 15MPa, the cold strength exceeds 90%, which is much higher than the strength of MSW under the same pressure (59%), and the hot strength TS +6 and TS +3 18% and 40%, respectively, which are higher than the strength of MSW under the same pressure (11% and 31%); the crucible expansion number is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com