Municipal solid wastes processing method and device thereof

A technology of municipal solid waste and its treatment method, which is applied in the field of municipal solid waste treatment method and its treatment device, which can solve problems such as difficult process and pulping of perishable substances, and achieve easy storage and transportation, rapid and complete combustion, and low operating cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw garbage enters the factory and is weighed and measured, then unloaded into the garbage sieve hopper, roughed by garbage sieve, and the oversize masonry and long organic matter with a particle size greater than 300mm are sorted out, and the undersize is pre-separated Choose trash.

[0027] The long organic matter with a particle size greater than 300mm is sheared and crushed until the particle size is not greater than 100mm, and then returns to the conveyor belt with permanent magnet rollers, and enters the trommel screen together with the pre-sorted waste under the screen for screening.

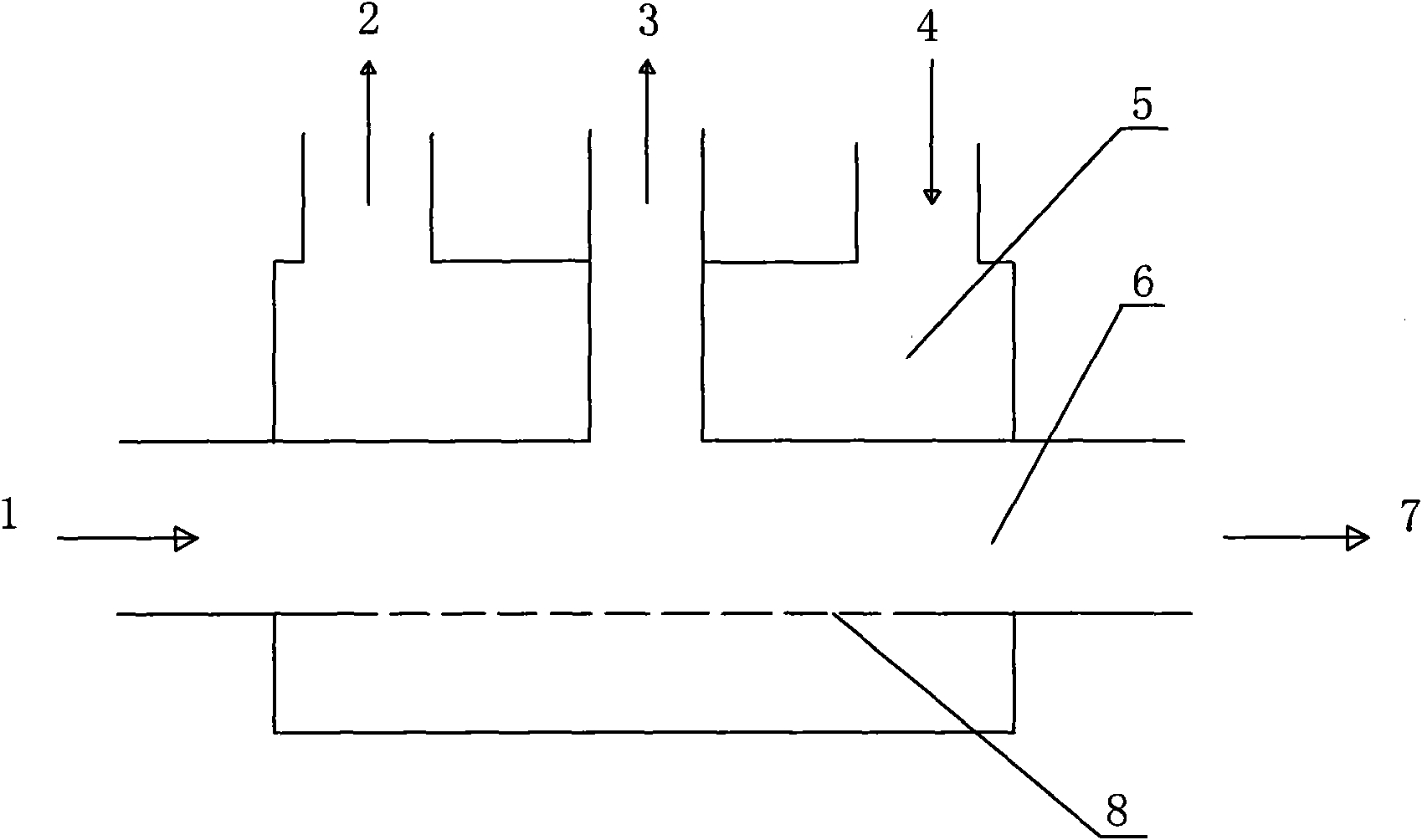

[0028] The undersize material with a particle size less than 20mm obtained from the drum sieve is collected for use, and the oversize material over 20mm is loaded by a tunnel car, and enters the inner cavity 6 of the tunnel oven from the feed port 1, and the temperature is controlled at 250-300 The material is dried at ℃, discharged from the discharge port 7, and then enters the wi...

Embodiment 2

[0037] Raw garbage enters the factory and is weighed and measured, then unloaded into the garbage sieve hopper, roughed by garbage sieve, and the oversize masonry and long organic matter with a particle size greater than 300mm are sorted out, and the undersize is pre-separated Choose trash.

[0038] The long organic matter with a particle size greater than 300mm is sheared and crushed until the particle size is not greater than 100mm, and then returns to the conveyor belt with permanent magnet rollers, and enters the trommel screen together with the pre-sorted waste under the screen for screening.

[0039] The undersize material with a particle size less than 20mm obtained from the drum sieve is collected for use, and the oversize material over 20mm is loaded by a tunnel car, and enters the inner cavity 6 of the tunnel oven from the feed port 1, and the temperature is controlled at 250-300 The material is dried at ℃, discharged from the discharge port 7, and then enters the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com