Energy supply method for production of garbage derived fuel and energy equilibrium deploying method

A technology for waste-derived fuel and energy supply, applied in the direction of fuel, gas fuel, waste fuel, etc., can solve the problems of low calorific value of RDF fuel, external power supply, and high production cost of RDF, so as to reduce production cost, improve calorific value, and widely adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

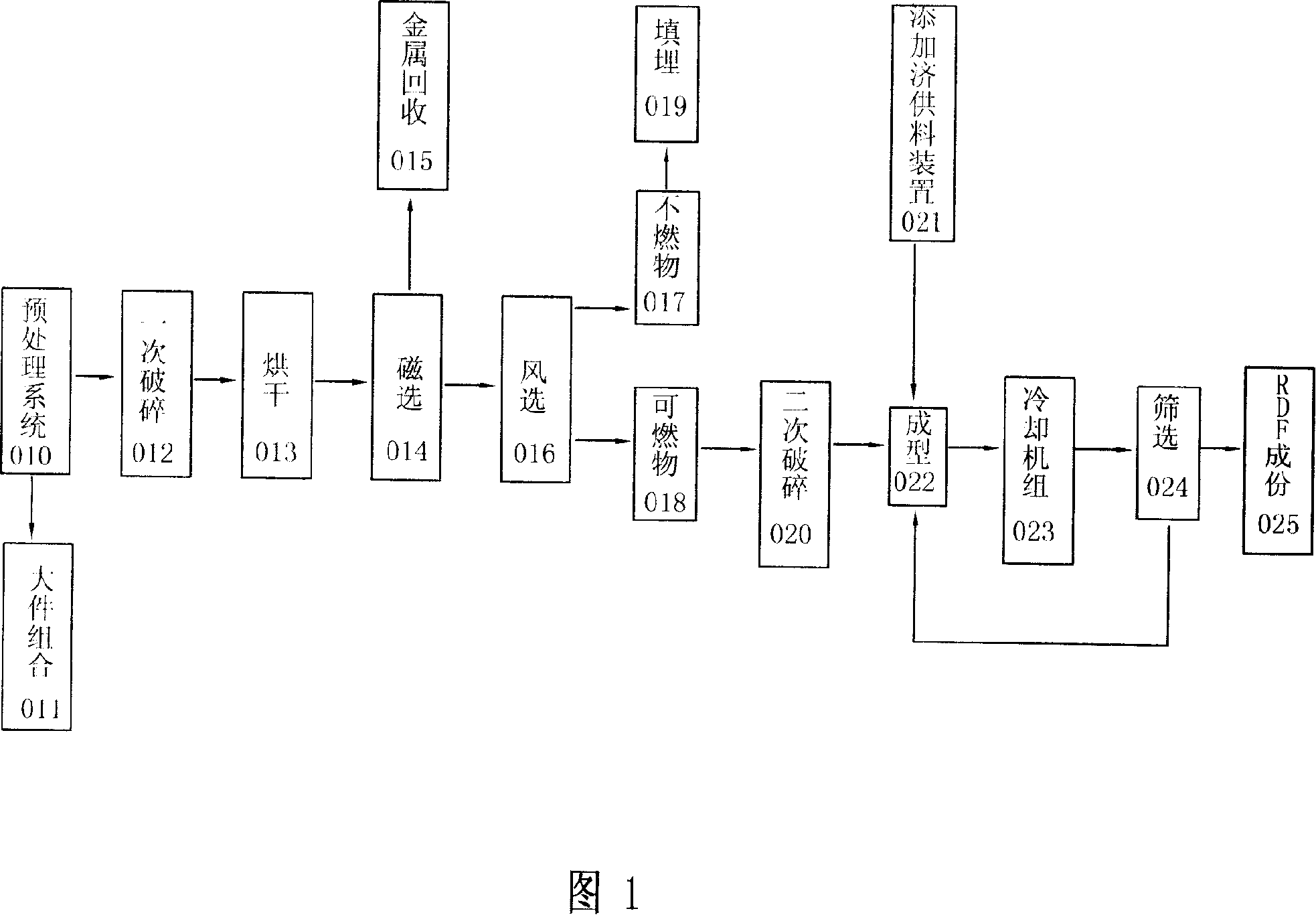

[0018] Refer to Figure 1, the flow chart of a typical production method of waste-derived fuels currently on the market. In the process of producing RDF, the raw waste is firstly pretreated010 to remove the bulky components011, and the remaining waste is crushed for the first time012 and dried by drying equipment013 , use magnetic separation equipment to perform magnetic separation 014 on the garbage, recover metal 015 in the garbage, pass the remaining part through the winnowing 016 system to screen combustible 018 and non-combustible 017, and landfill the non-combustible 017 019 treatment, the combustibles 018 are sent to the secondary crushing 020 system for fine crushing again, the processed garbage is added to the additive 021 for garbage forming 022 treatment, cooling unit 023 for cooling treatment, and finally sieving 024 to filter the qualified p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com