System for extracting rubbish derived fuel (RDF) from municipal rubbish

A garbage-derived fuel and municipal garbage technology, applied in the field of waste-derived fuel extraction system, can solve the problems of increasing CO2 emissions, not effectively solving the effective classification and treatment of non-combustible components, and the outage of the garbage treatment process chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

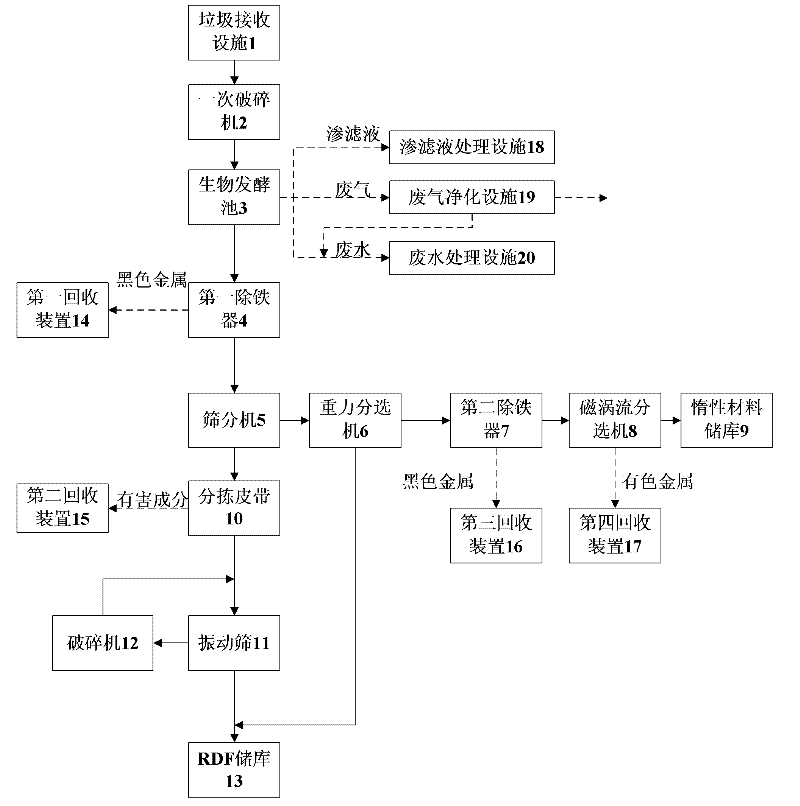

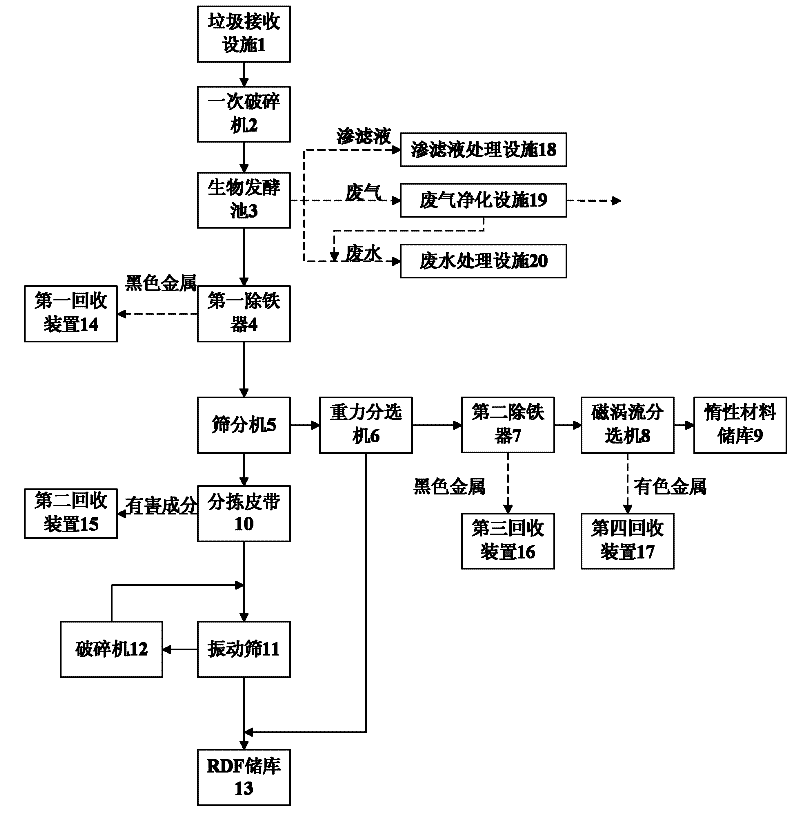

[0012] Such as figure 1 As shown, a system for extracting garbage-derived fuel from municipal garbage, which includes a garbage receiving facility 1, a primary crusher (ie the first crusher) 2, a biological fermentation tank 3, a first iron remover 4, a screening machine 5, Gravity separator 6, second iron remover 7, eddy current separator 8, inert material storage 9, sorting belt 10, vibrating screen 11, second crusher 12, RDF storage 13, leachate treatment facility 18, Exhaust gas purification facility 19, waste water treatment facility 20; Garbage receiving facility 1 receives municipal waste (or claims primary garbage, domestic garbage), and a conveying device is provided between the garbage receiving facility 1 and the input port of the primary crusher 2 (garbage receiving facility 1 The received municipal waste is sent into the primary crusher 2 by the conveying device), and a conveying device is provided between the output port of the primary crusher 2 and the biologica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com