Preparation method for preparing derived fuel by utilizing combustible materials in garbage

A technology for derived fuel and garbage, applied in the field of preparation of fuel derived from combustibles, can solve the problems of ineffective control of harmful substances in derived fuel, low calorific value of derived fuel, low sorting and bag breaking rate, etc. The effect of maximizing resource utilization, low production cost and unbreakable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

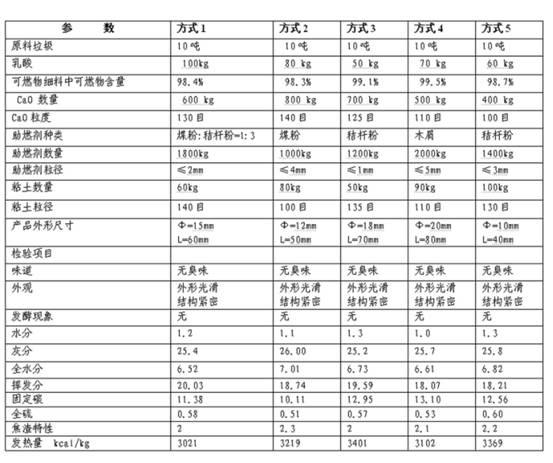

[0030] For the preparation method of using combustibles in garbage to prepare derivative fuel, the specific parameters of each embodiment are shown in Table 1. The specific process is as follows:

[0031] (1) Disinfection

[0032] Spray evenly with 0.5% to 1% of the total weight of raw material waste with lactic acid, and the industrial lactic acid is a marketable product;

[0033] (2) Rough selection of garbage

[0034] Urban and rural garbage is first manually sorted, and large objects are sorted out; then crushing, screening, gravity separation, winnowing, magnetic separation, and particle size selection are used to separate urban and rural garbage into organic matter, inorganic matter, combustible matter, and plastic. , Ferromagnetic materials, metals, etc., take combustible raw materials for later use. The combustibles are: at least one of plant flowers, leaves, fruits, stems, stems, roots, animal skins, hair, paper, fabrics, and textiles. The equipment is a fully automatic garb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com