Eddy current sorter for separating non-ferrous metals in solid waste

A non-ferrous metal and eddy current technology, which is applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of inaccurate selection of related parameters, low separation rate of eddy current separator, and unfavorable structural design, etc. Achieving the effect of high sorting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

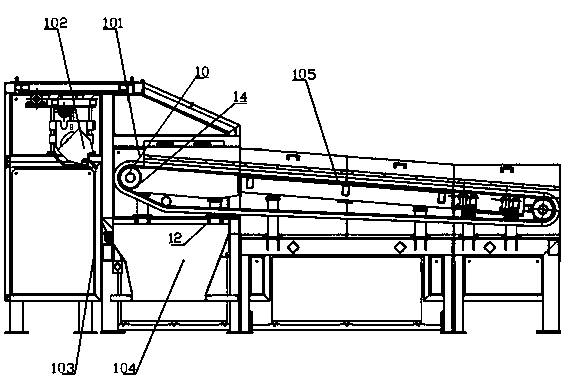

[0017] see Figure 1~Figure 3 , This eddy current separator for separating non-ferrous metals in solid waste includes collecting troughs 103, 104, vibrating table 101 and belt conveyor 105, and is characterized in that: the collecting troughs 103, 104 and the vibrating table 101 The vibrating table 101 is connected to the belt conveyor 105. At the end of the belt conveyor 105, there is a concentric driven roller 14 that rotates with the conveyor belt, and a baffle plate that contacts the conveyor belt is provided near the bottom of the roller 14. 12. A collecting trough 104 is arranged below the concentric driven drum, and a magnetic roller 13 is arranged in the concentric driven drum 14; its upstream equipment is a vibrating feeder, which evenly disperses the material on the belt 105 of the eddy current separator When the material passes through the magnetic roller 13, an eddy current is generated inside the conductive non-ferrous metal, and the eddy current will also generat...

Embodiment 2

[0018] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

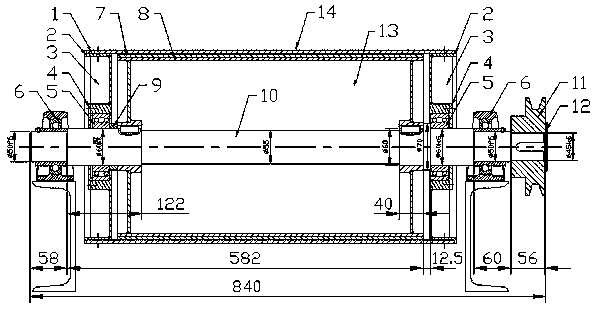

[0019] The roller group is composed of a driven roller 14, a driven shaft 10, a web 2, and a driven roller shell 1. The roller bearing adopts a self-aligning ball bearing 5; the driven roller 14 and the driven shaft 10 can rotate relative to each other. , the sliding bearing 6 needs to be installed to meet the requirements; the web 2 and the driven drum shell 1 need to be detachable, so bolts are used. In addition, a magnetic roller 13 needs to be placed inside the driven drum 14, and the magnetic roller 13 is mainly composed of a magnet 7, a sleeve 8 and a magnetic yoke 9; the magnet 7 is fixed on the magnetic yoke 9, and the magnetic poles of the adjacent magnets 7 are opposite in polarity; The outside of the magnet 7 is provided with a non-magnetic sleeve 8, which fixes the magnet 7 and prevents foreign matter from entering and affecting its work. The rota...

Embodiment 3

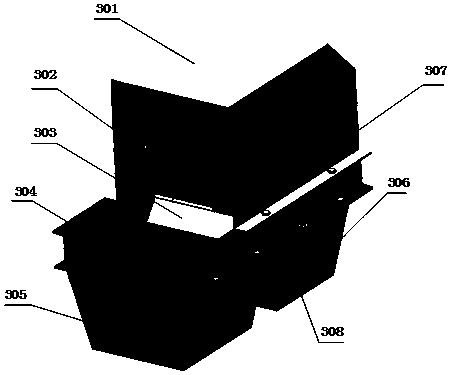

[0023] like Figure 1~Figure 2 As shown, the eddy current sorting machine for separating non-ferrous metals in solid waste, in the sorting machine, the front end of the conveyor belt 105 is provided with a liftable vibrating table 101, and the front end of the vibrating table is provided with a deflection nozzle array 102, A non-ferrous metal material collecting tank 104 is provided below the deflecting nozzle array 102, and a non-metallic material collecting tank 103 is provided on the front side of the non-ferrous metal material collecting tank 104. The deflection nozzle array 102 and the high-pressure gas supply pipe Connection; the vibrating table 101 is connected to the belt conveyor line 105, and the tail end of the belt conveyor 105 is provided with a concentric driven roller 14 that rotates with the conveyor belt, and a magnetic roller 13 needs to be placed inside the driven roller, such as figure 2 The driven roller shaft structure is provided with a baffle plate 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com