Composite dosage forms

a technology of compound and dosage forms, which is applied in the direction of shaping presses, microcapsules, drug compositions, etc., can solve the problems of reducing the production efficiency of compound coating systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

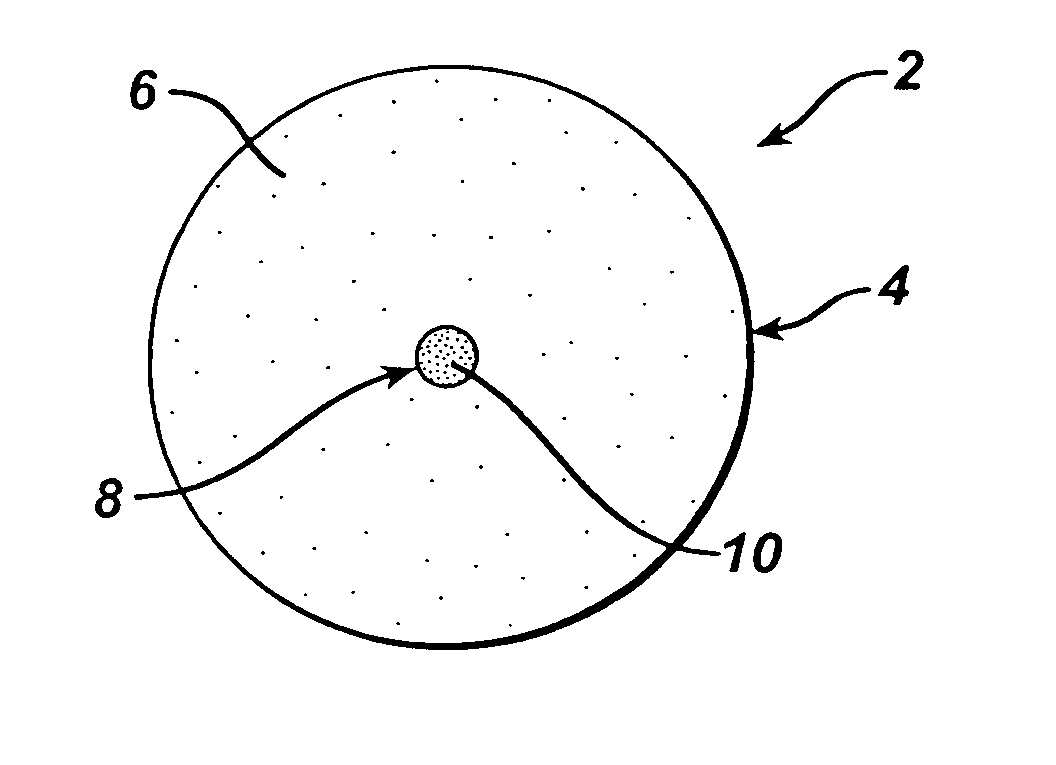

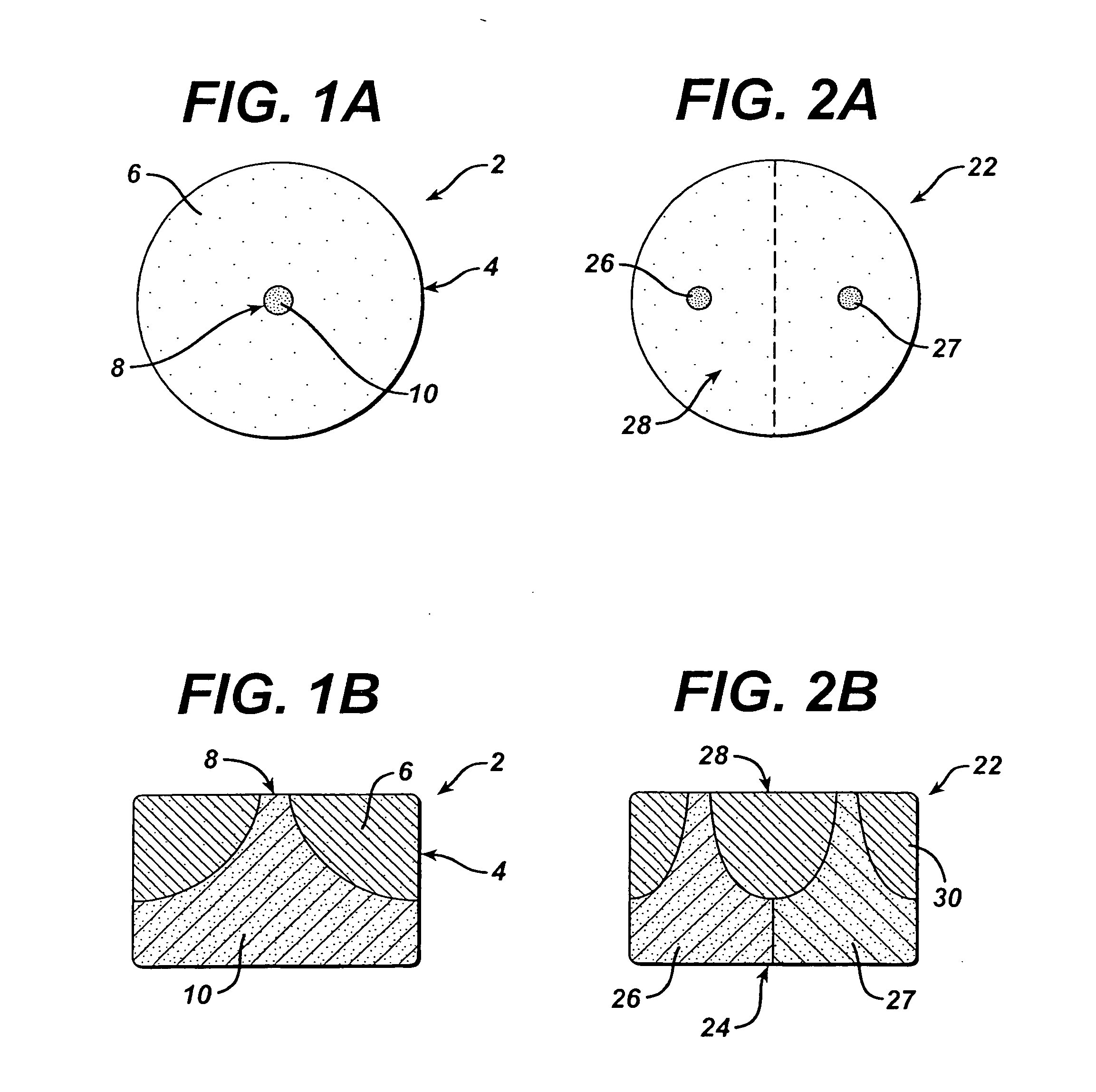

[0249] Dosage forms of the invention are made in a continuous process using an apparatus comprising a thermal cycle molding module and a compression module linked in series via a transfer device as described at pages 14-16 of copending U.S. application Ser. No. 09 / 966,939, the disclosure of which is incorporated herein by reference. The dosage forms have the structure shown in FIGS. 1A and 1B and comprise a first portion comprising a first molded material and a second portion comprising a second material that is compressed.

[0250] The first portions are made of a flowable material comprising the following ingredients:

WeightMg / TabletTrade NameManufacturer%TabletPolyethyleneCarbowax ®Union Carbide60.3190Glycol 3350Corporation,Danbury, CTCroscarmelloseAc-Di-Sol ®FMC Corporation,30.195SodiumNewark, DEPseudoephedrineBASF9.530HydrochloridePharmaChemikalienCrystalGmbH & Co.,Ludwigshafen / Rhein.

[0251] The second portions are made of a dry blend comprising the following ingredients: acetami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com