Control circuit of powder feeder for hypersonic flame spraying

A supersonic flame, control circuit technology, applied in general control systems, program control, electrical program control, etc., can solve the problems of low processing efficiency, poor controllability, and the spraying process cannot be carried out normally, so as to reduce costs and improve delivery. The effect of powder efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

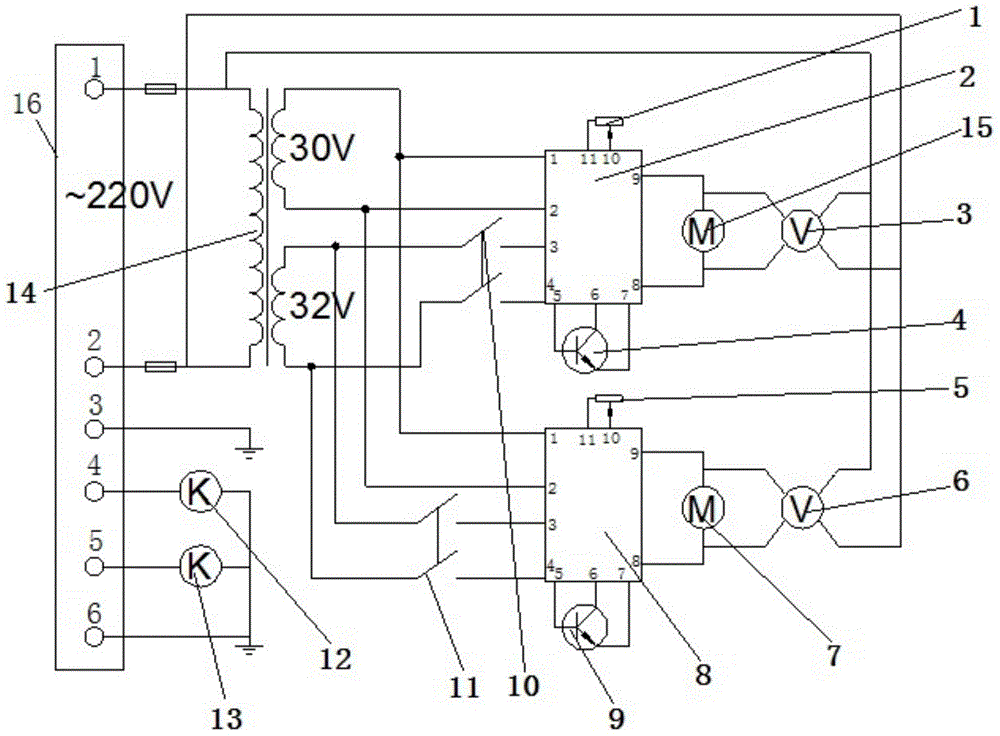

[0015] Such as figure 1 As shown, a control circuit of a powder feeder for supersonic flame spraying, including potentiometer one 1, speed control board one 2, voltmeter one 3, power tube one 4, potentiometer two 5, voltmeter two 6, motor Two 7, speed control board two 8, power tube two 9, switch one 10, switch two 11, solenoid valve one 12, solenoid valve two 13, transformer 14, motor one 15 and plug-in strip 16, and the transformer 14 includes incoming lines side, 30V output terminal and 32V output terminal, the incoming line side of the transformer 14 is connected to 220V alternating current and then connected to pin 1 and pin 2 of the socket 16, and pin 1 and pin 2 of the speed control board 1 are respectively connected to On the 30V output terminal of the transformer 14, the 32V o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com