Preparation method of road sealant

A sealant and road technology, applied in the direction of chemical instruments and methods, adhesives, other rubber adhesives, etc., to achieve the effects of easy melting, increased mixing uniformity, low temperature resistance and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

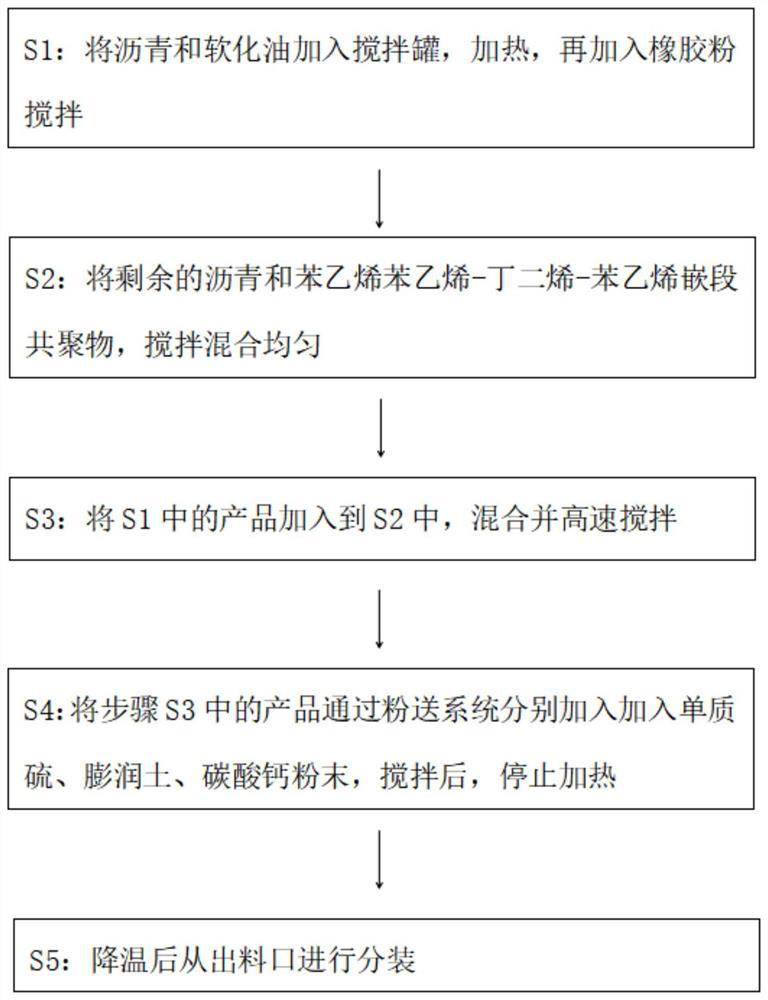

[0049] see figure 1 , a kind of preparation method of road sealant, described preparation method comprises the following steps:

[0050] S1: Add asphalt and softened oil to the mixing tank through the feeding port, turn on the heating controller to heat; then add rubber powder through the powder feeding mechanism, turn on the motor to stir for 20-30 hours, take it out from the feeding port, and keep warm for later use ;

[0051] S2: Stir and mix the remaining asphalt and styrene-styrene-butadiene-styrene block copolymer evenly.

[0052] S3: Add the product in S1 to S2, mix and stir at high speed.

[0053] S4: After adding elemental sulfur, bentonite, and calcium carbonate powder into the product in step S3 respectively through the powder delivery system and stirring, then stop heating, open the circulation pump and condenser, and continue to cool down through the condensing pipe.

[0054] S5: Cool down to 120-130°C, and get the final road sealant from the outlet. The parti...

Embodiment 2

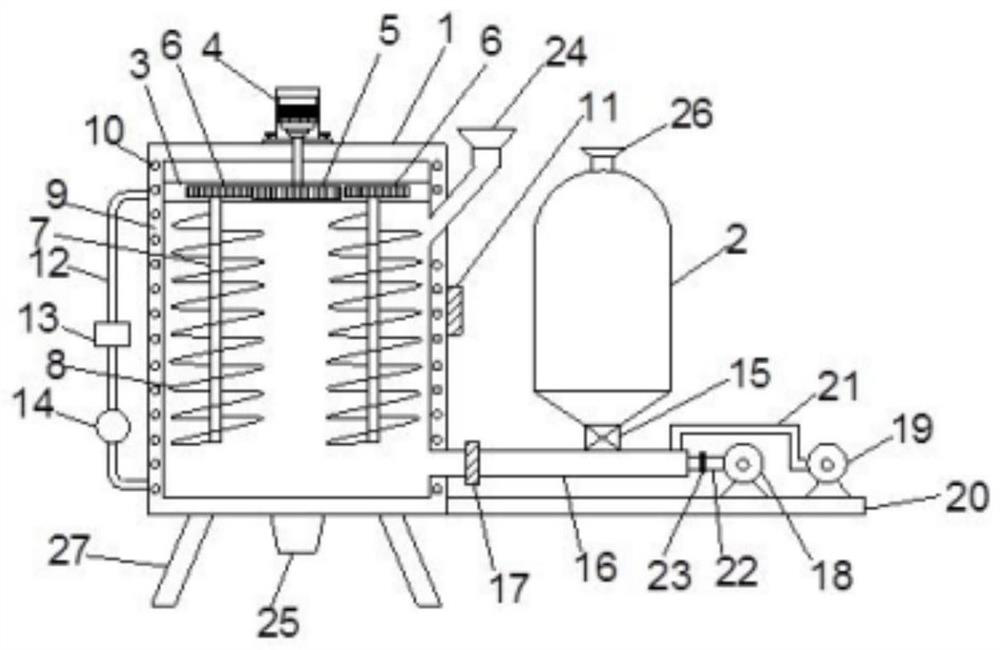

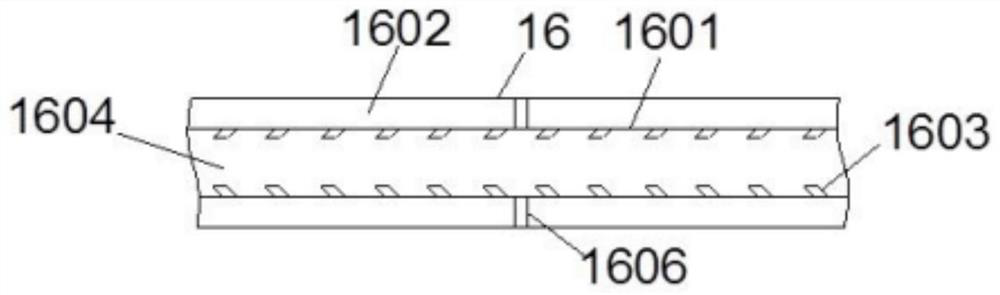

[0061] see Figure 2-4 , a preparation device for road sealant; comprising a stirring tank 1, a storage tank 2, and a powder feeding mechanism; the side wall of the stirring tank 1 is a double-layer structure, and a heating chamber 9 is arranged between the inner wall and the outside of the stirring tank 1, The heating chamber 9 is provided with a heating medium; the heating chamber 9 is provided with a heating resistance wire 10, and the heating resistance wire 10 is evenly wound around the inner wall of the stirring tank 1; the heating resistance wire 10 is connected to a heating controller 11 to heat The controller 11 is heated on the outer wall of the stirring tank 1; the heating chamber 9 is connected with a condensing pipe 12 symmetrically on the upper and lower sides, and the condensing pipe 12 is arranged on the outside of the stirring tank 1, and the condensing pipe 12 is connected with a condenser 13 for condensing The other end of the device 13 is connected with a c...

Embodiment 3

[0067] A preparation method of road sealant, said preparation method may further comprise the steps:

[0068] S1: Add asphalt and softened oil to the mixing tank through the feeding port, turn on the heating controller to heat; then add rubber powder through the powder feeding mechanism, turn on the motor to stir for 20-30 hours, take it out from the feeding port, and keep warm for later use ;

[0069] S2: Stir and mix the remaining asphalt and styrene-styrene-butadiene-styrene block copolymer evenly.

[0070] S3: Add the product in S1 to S2, mix and stir at high speed.

[0071] S4: After adding elemental sulfur, bentonite, and calcium carbonate powder into the product in step S3 respectively through the powder delivery system and stirring, then stop heating, open the circulation pump and condenser, and continue to cool down through the condensing pipe.

[0072] S5: Cool down to 120-130°C, and get the final road sealant from the outlet.

[0073] The particle diameter of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com