Slider structure for three-beam and four-post hydraulic press

A hydraulic press and sliding block technology, applied in the field of hydraulic presses, can solve the problems of increasing the manufacturing cost of the sliding block, long single cycle time, and increasing the stroke of the powder feeding cylinder, saving manufacturing materials and costs, improving the powder adding efficiency, shortening the effect of itinerary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

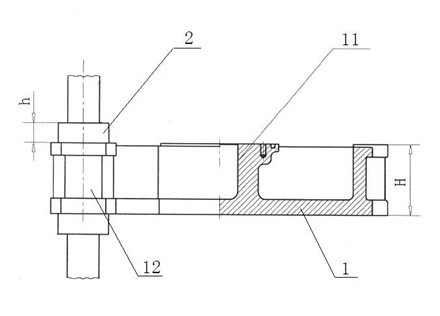

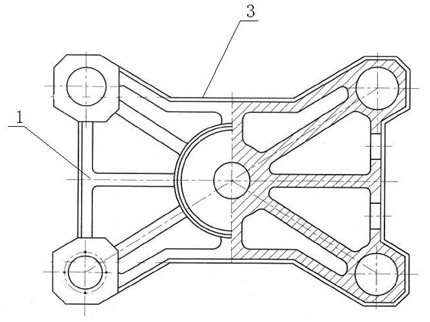

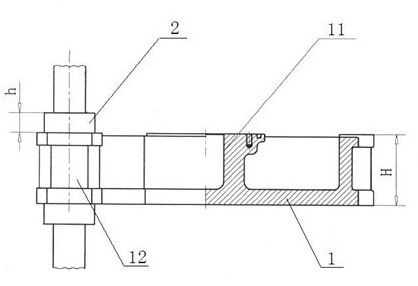

[0009] Such as figure 1 , 2 As shown, it includes the slider main body 1, the center of the slider main body 1 is the main cylinder piston rod connecting seat 11, the four corners are provided with guide sleeve mounting seats 12, and guide sleeves are installed in each guide sleeve mounting seat 12, and the guide sleeve The upper and lower flange ends 2 respectively protrude from the guide sleeve mounting seat 12, and the extension distance h is 1 / 4-1 / 3 of the thickness H of the guide sleeve mounting seat. The length does not change. In this embodiment, the thickness H of the guide sleeve mounting seat 12 is 280 mm, and the protruding distance h of the flange end is 80 mm. However, the slider with the traditional structure needs to achieve the same guide length, and the thickness of the slider, that is, the guide sleeve mounting seat, needs to reach About 400mm. On the longer side wall of the slider main body 1, an inwardly recessed notch 3 is provided, which is an inverted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com