Powder spraying system convenient to clean

A technology of powder spraying and cleaning device, which is applied in spray booths, spray devices and other directions, can solve the problems of low powder loading efficiency of automatic spray gun, powder spillage of automatic spray gun mouth, long time consuming for color change and cleaning work, etc., and achieves fast color change and cleaning work. , Reduce the amount of powder leakage, the effect of high efficiency of color changing and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

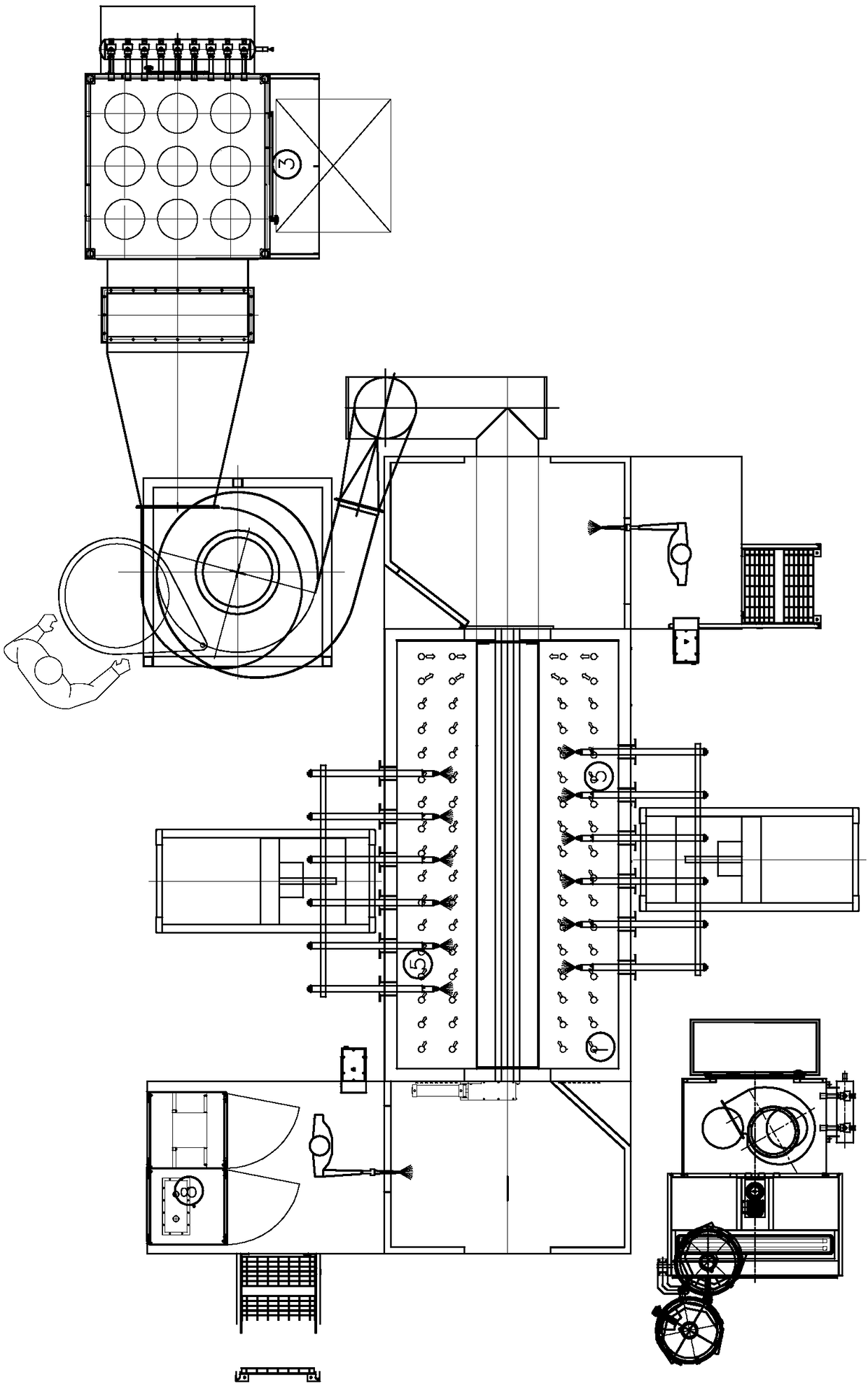

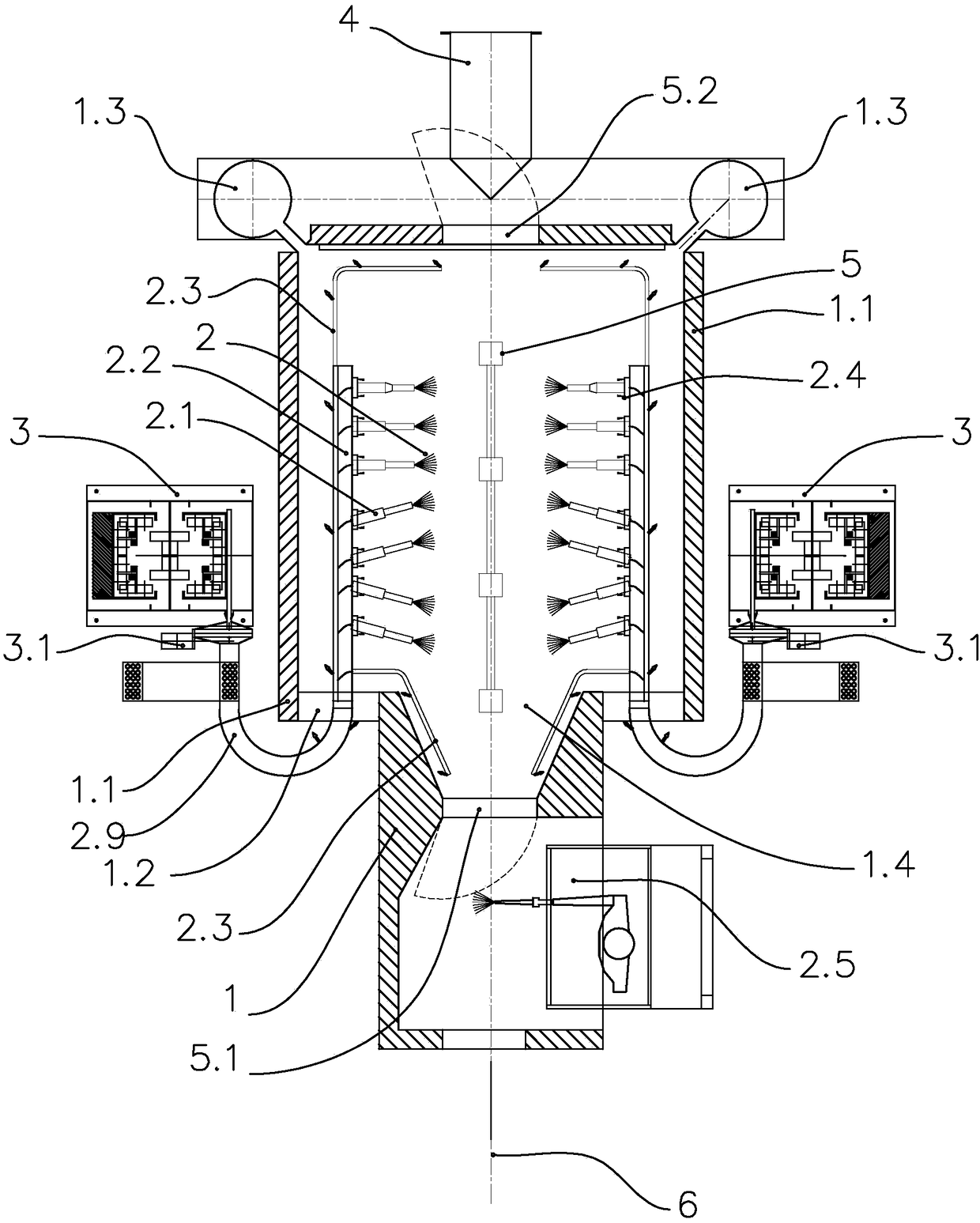

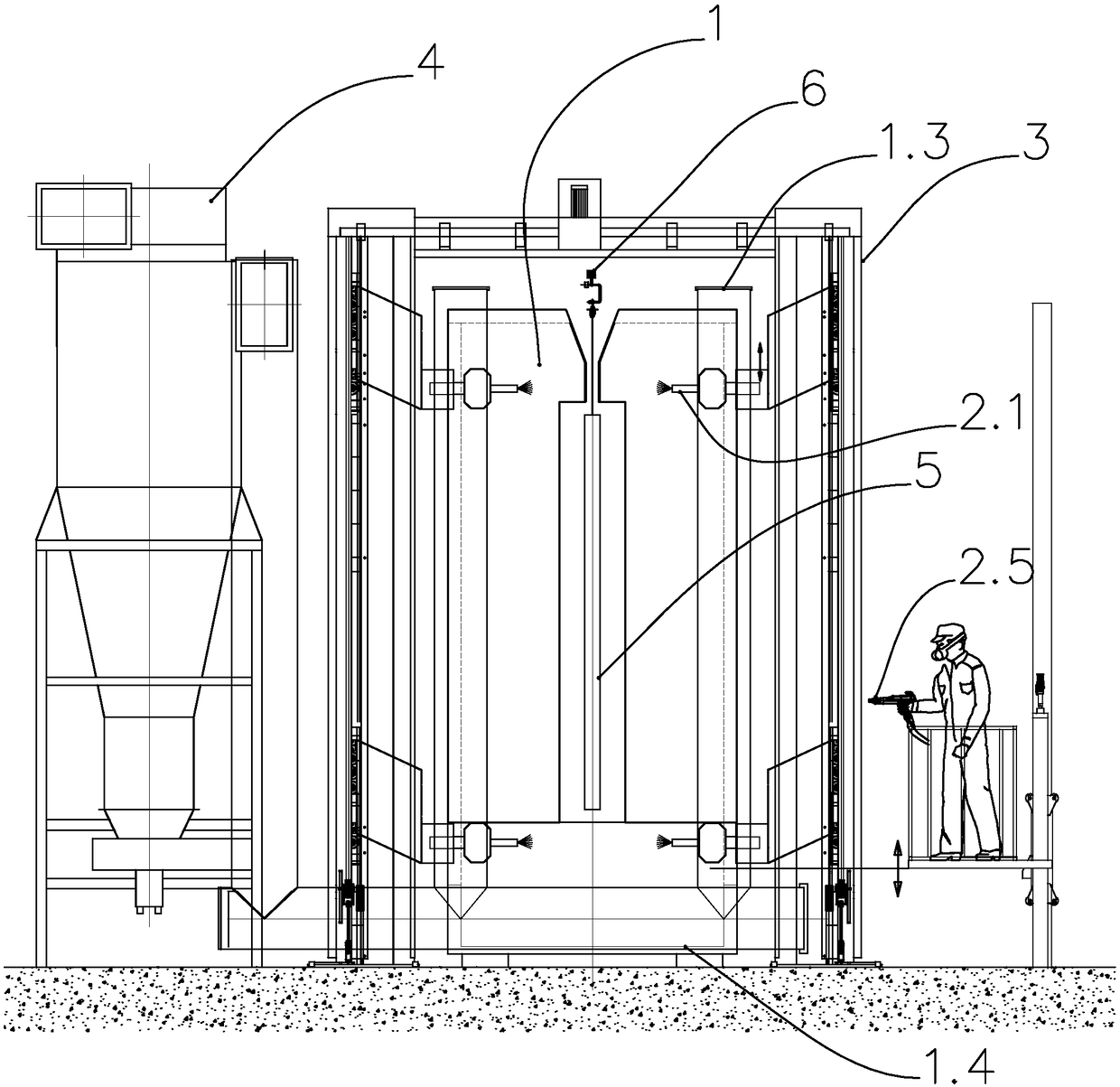

[0028] refer to figure 2 , image 3 , figure 2 and image 3 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a powder spraying system that is easy to clean includes a spray booth body 1, an automatic spray gun system 2, a vertical reciprocating device 3 and an exhaust system 4 that surround the spray area.

[0029] like figure 2 As shown, the spray booth body 1 includes a side plate assembly 1.1, a top plate assembly, a bottom plate assembly 1.4, and an exhaust duct assembly. The side plate assembly 1.1 includes a spray gun beam opening slot 1.2 parallel to the movement direction of the conveying chain 6. In this In the embodiment, the number of opening slots 1.2 of the spray gun beam on each side is only one, and the number of opening slots 1.2 of the spray gun beam is limited to be less than the number of automatic spray guns 2.1 arranged horizontally as shown in the top view projection of the automatic spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com