Rotary nozzle structure of medium-speed coal mill

A technology of rotating nozzles and coal mills, applied in the field of machinery, can solve problems such as easy wear of nozzles, increased power consumption of fans, and increased ventilation resistance of coal mills, achieving good wear resistance and impact resistance, saving electricity and Use wind to ensure the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

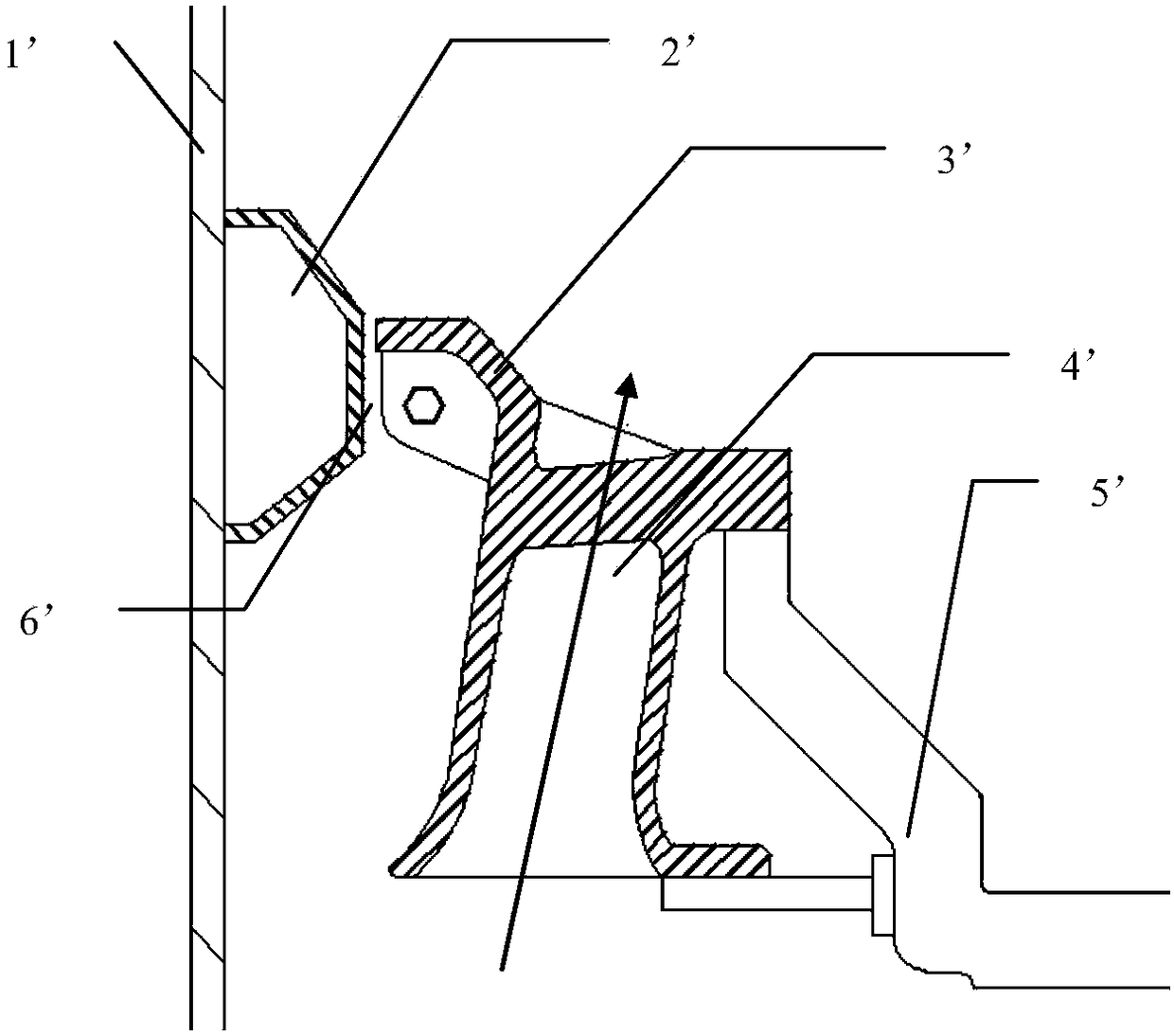

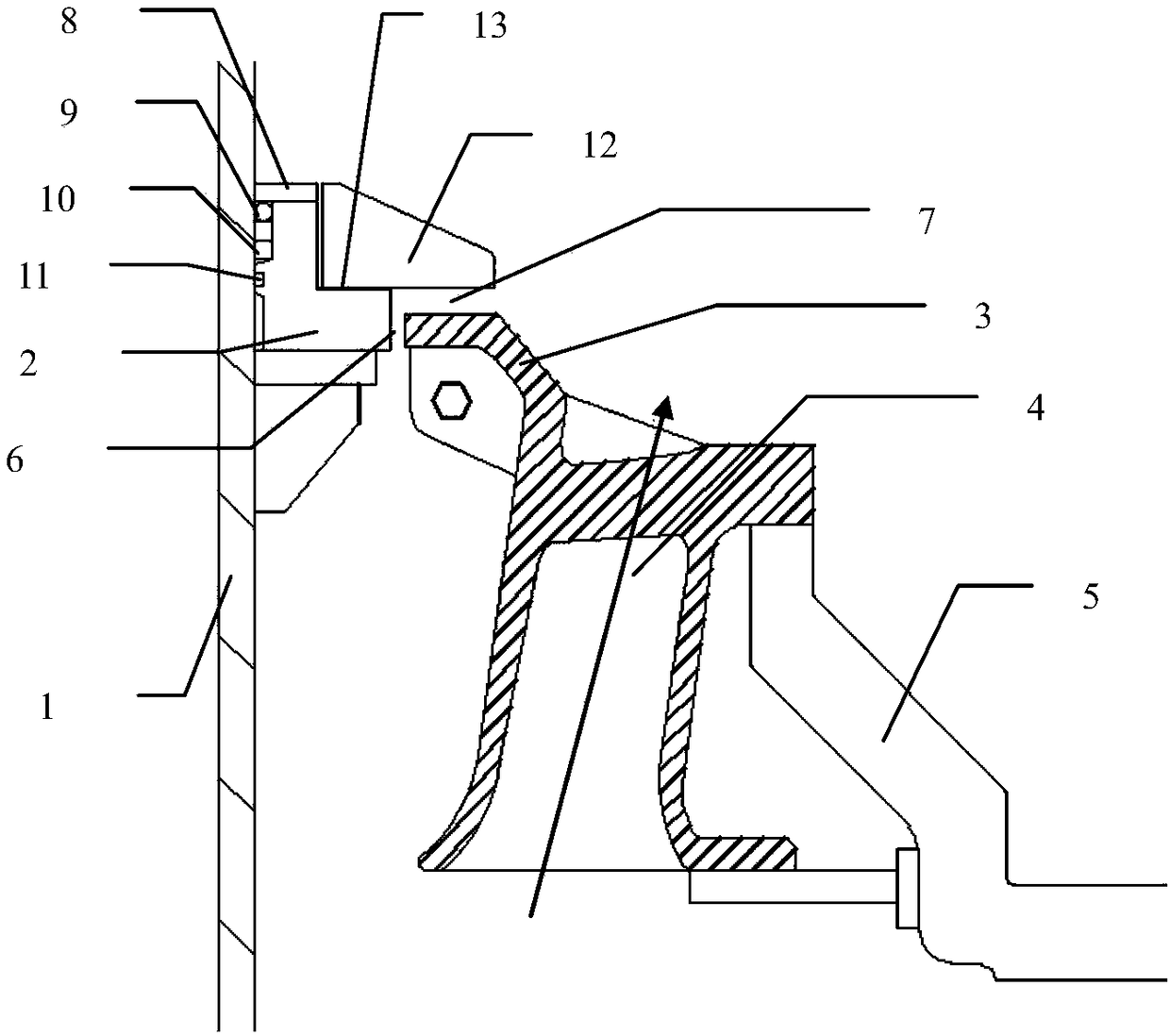

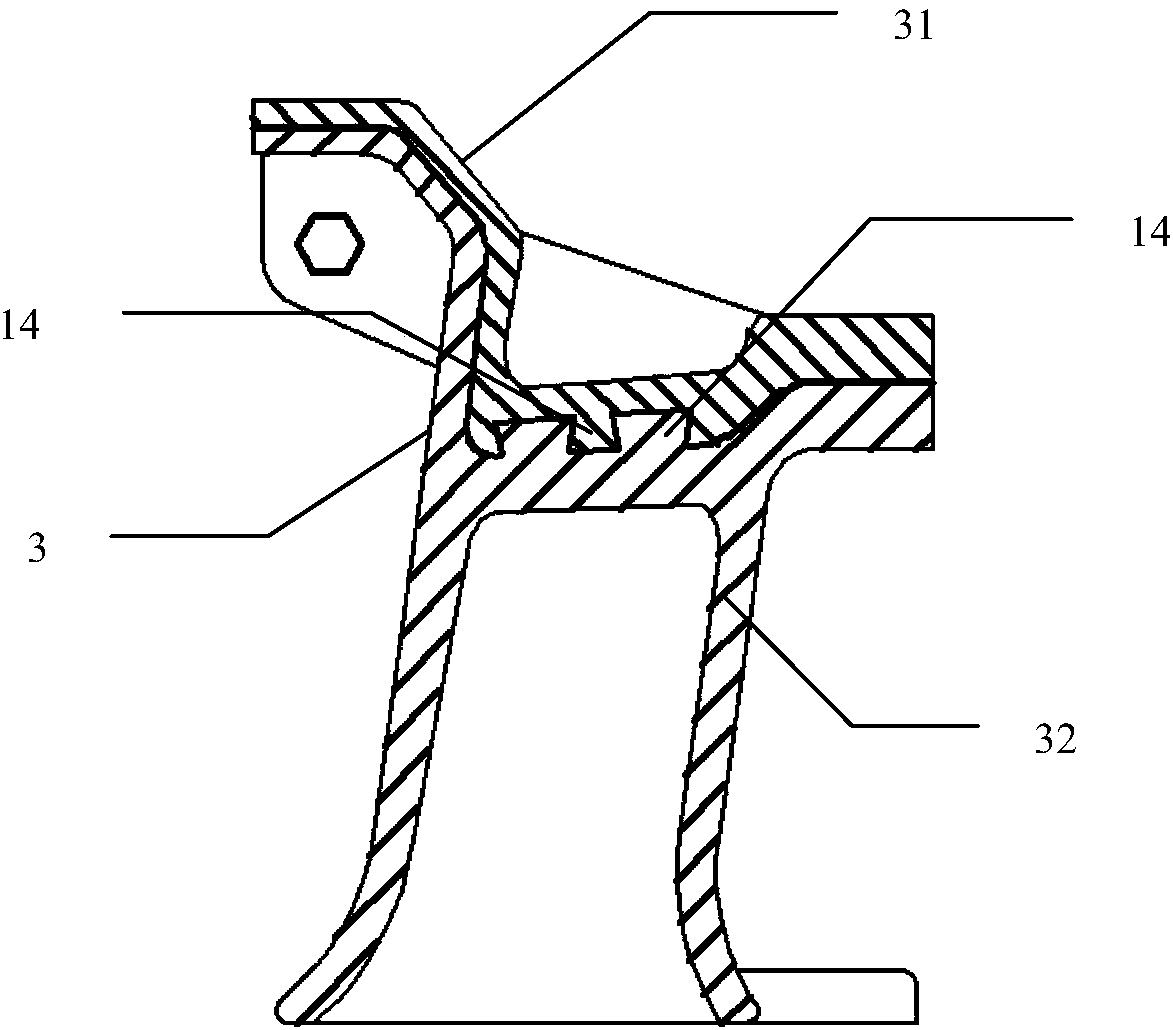

[0031] Such as figure 2 As shown, the rotary nozzle structure of the medium-speed coal mill of the present invention includes: a static ring 2 is provided at the inner cylinder wall 1 of the coal mill; a nozzle 3 is provided on the grinding disc 5 of the coal mill; a nozzle 3 is provided on the nozzle 3 Air channel 4; a sealing structure is provided above the nozzle 3, and a vertical gap 6 and a horizontal gap 7 are formed between the sealing structure and the nozzle 3; the sealing structure is provided to ensure the sealing of the static ring 2 outside, which includes Pressing plate 8, round steel 9, asbestos packing 10, static ring sealing teeth 11, retaining ring 12, asbestos gasket 13.

[0032] Among them, on the side of the static ring 2, a pressure plate 8, a round steel 9, an asbestos packing 10, and a static ring sealing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com