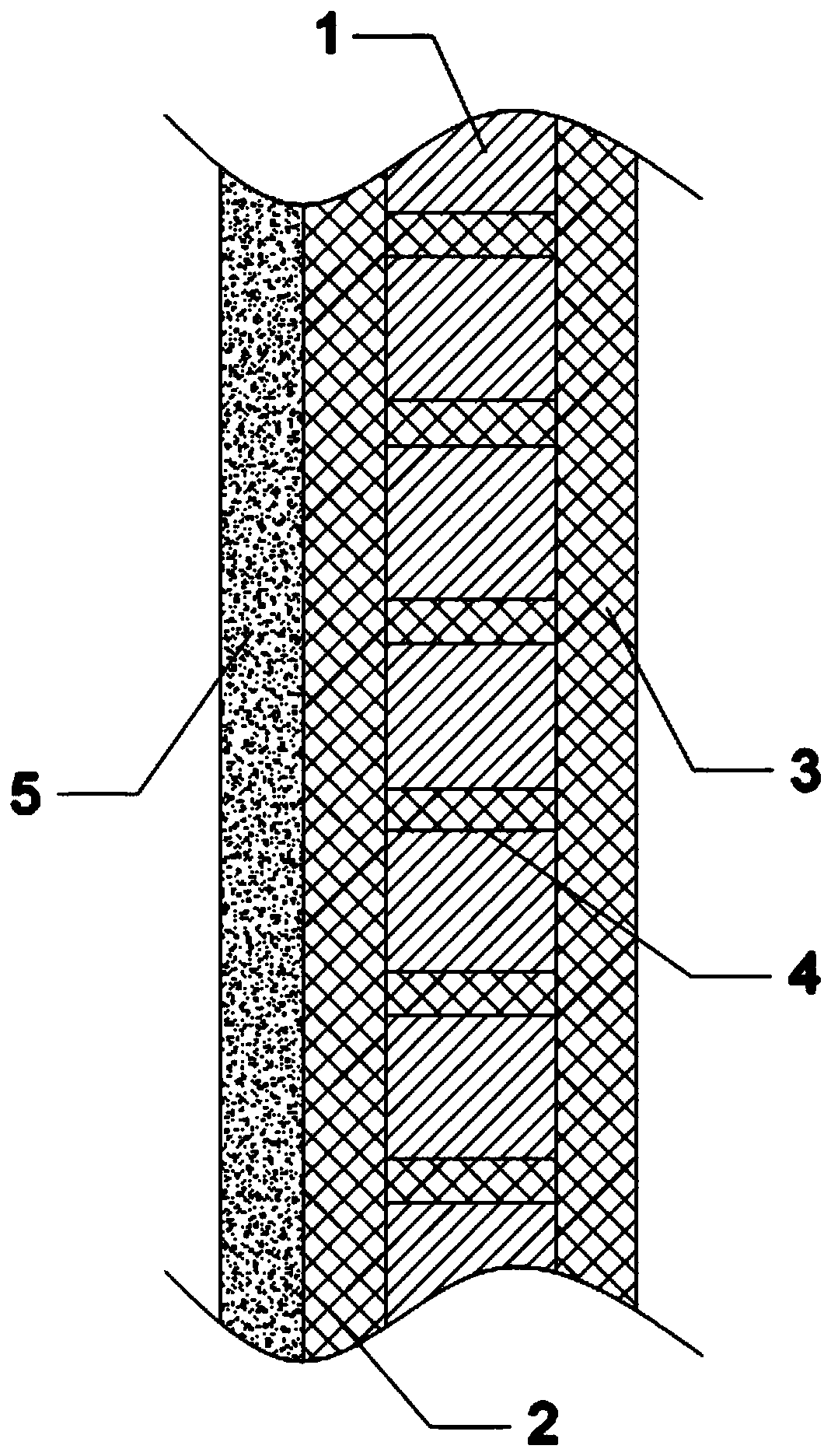

Corrosion-resistant lathe shell and production method thereof

A kind of anti-corrosion and lathe technology, applied in the direction of anti-corrosion coating, coating, special surface, etc., can solve the problems of metal plate exposure, short service life, paint peeling, etc., and achieve the goal of reducing noise pollution, multiple functions, and increasing space size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Wherein, the preparation method of the raw material of composite coating 5 comprises the following steps:

[0035] S1: Prepare a 16-50g / L FeCl3 solution and then ultrasonically stir for 30min, disperse the halloysite nanotubes with a mass ratio of ferric chloride (FeCl3) to halloysite (HNTs) of 2-3:1 in the In ionized water, ultrasonically stir for 20 minutes;

[0036] S2: Under strong stirring in a water bath at 45°C, slowly drop the halloysite nanotube suspension into the ferric chloride solution, stir for 10 minutes, then add 10 mL of 0.5% polyvinyl alcohol solution dropwise, stir vigorously for 10 minutes, then add 5 g of urea After continuing the reaction for 30 minutes, the temperature was raised to 80 degrees, and the pH was adjusted to 7-9 with 10% ammonia water, and the reaction was continued for 4 hours. The reaction product was centrifuged, washed repeatedly with distilled water, dried in vacuum, ground, and calcined at 350 degrees Celsius for 3 hours. Obtai...

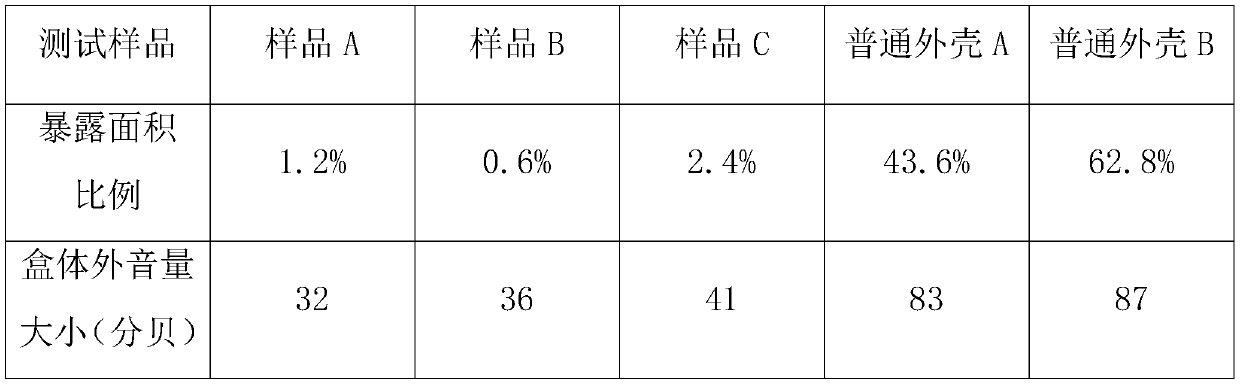

Embodiment

[0047] According to the above-mentioned preparation method, the samples were produced and tested, and the parts by weight of each sample protective layer and composite coating 5 components are as follows:

[0048] Sample A:

[0049] In the protective layer, there are 4 parts of epoxy resin, 3 parts of steel fiber, 0.7 part of dimethyl silicone oil, 0.2 part of retarder, 0.3 part of polyphenylene sulfide, 0.8 part of toughening agent, 3 parts of magnesite cementitious material, and 0.2 parts of toluene, 0.1 parts of coagulation regulator, and 0.08 parts of water reducing agent. Composite coating 5 includes 4 parts of epoxy resin, 5 parts of Fe2O3-HNTs hybrid material, 2 parts of silica fume, 0.6 part of m-cresol, 0.4 part of dopamine, and 0.2 part of admixture. Wherein, the weight ratio of the polycarboxylate high-efficiency water reducer and the early strength agent in the admixture is 1:2.4.

[0050] Sample B:

[0051] In the protective layer, there are 6 parts of epoxy re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com