Chlorosulfonated polyethylene voltage-resistance and high-performance special anticorrosive paint and production method thereof

A technology of chlorosulfonated polyethylene and high chlorinated polyethylene, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc. It does not have problems such as low temperature resistance and high pressure resistance, and achieves the effects of good supporting performance, long corrosion protection period and strong galvanic corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

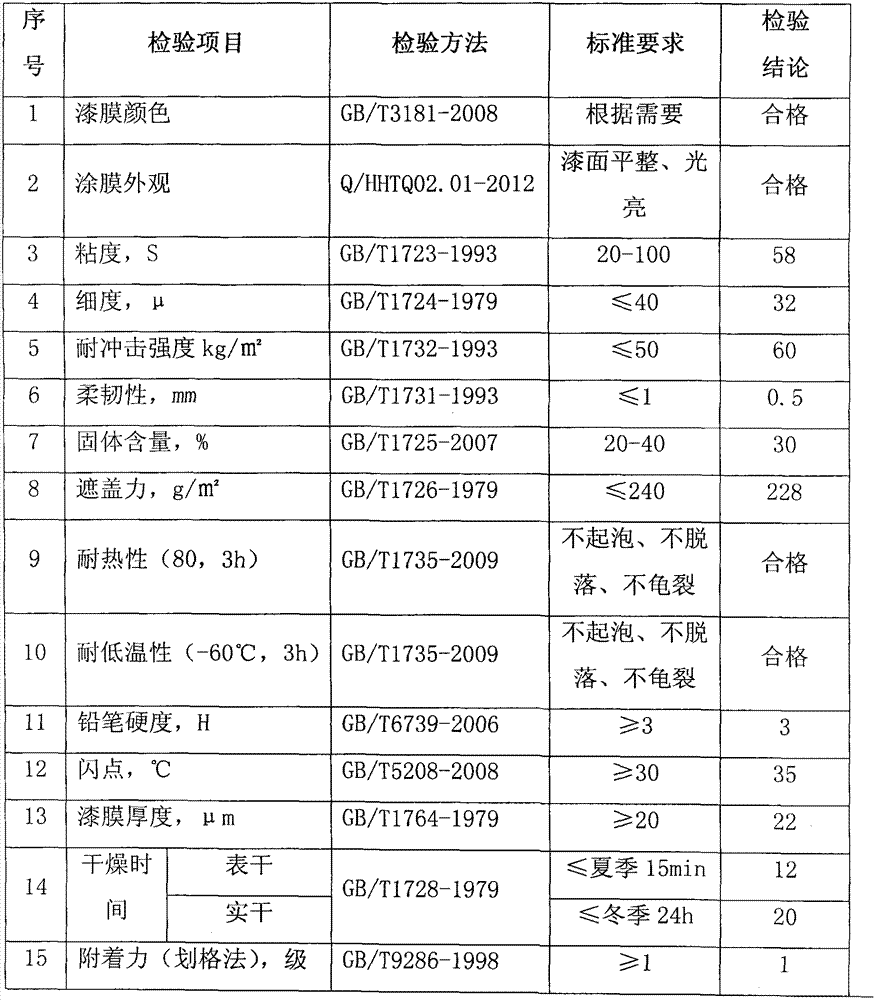

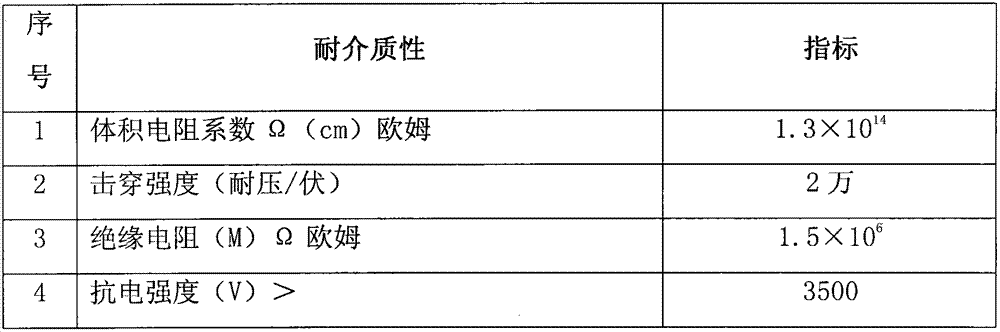

[0013] The present invention is a chlorosulfonated polyethylene anti-voltage high-performance special anti-corrosion coating. The components of the anti-corrosion coating are: 50 kg of chlorosulfonated polyethylene, 20 kg of acrylic polyurethane, 50 kg of high-chlorinated polyethylene, 500 kg of xylene, and chlorination method Titanium dioxide 49.8kg, phthalocyanine blue 5kg, phthalocyanine green 5kg, iron red powder 30kg, ultramarine 5.2kg, o-xylene 200kg, mica flakes 25kg, zinc powder 30kg, n-butanol 15kg, turpentine 15kg.

[0014] Implement the production method of product of the present invention to be:

[0015] 1. First, add chlorosulfonated polyethylene, acrylic polyurethane, and high-chlorinated polyethylene to 40kg of xylene to dissolve to make a liquid material. Pour each liquid material into the preparation kettle and mix for 20 minutes to make it react.

[0016] 2. Pour the prepared liquid material into the hot mixer for rolling and mixing. At the same time, add chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com