Powder adding device used for printer powder adding

A technology of a powder adding device and a printer, which is applied in the fields of electrical recording technology using charge graphics, equipment for using electrical recording technology using charge graphics, and electrical recording technology, and can solve problems such as damage to toner cartridges, waste of toner, and complicated storage. To achieve the effect of improving powder feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

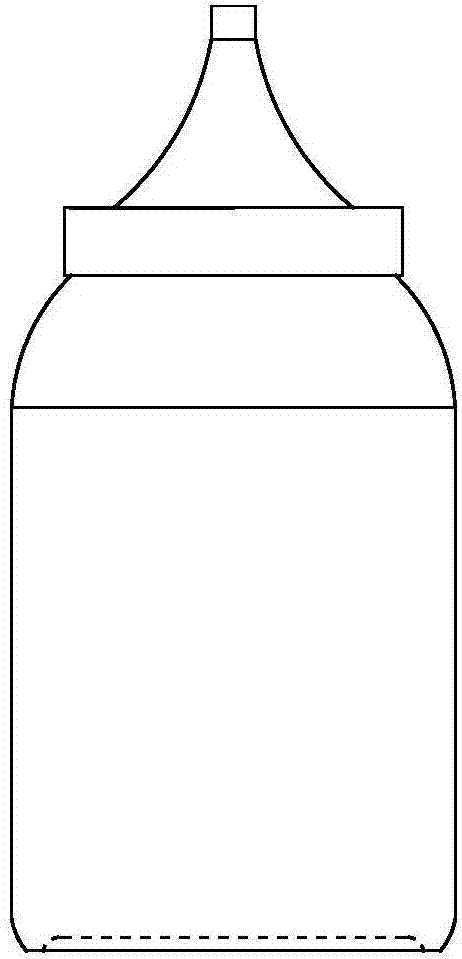

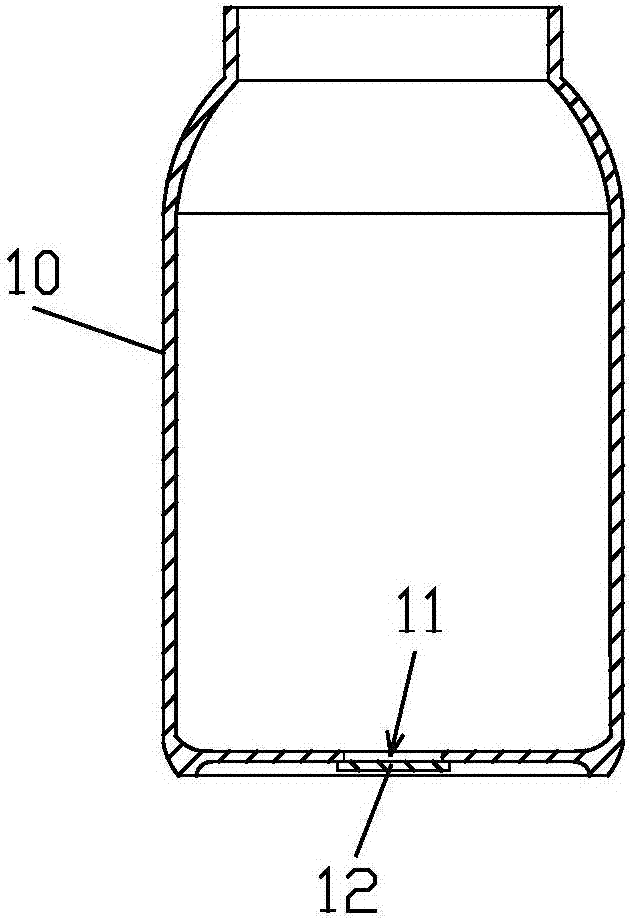

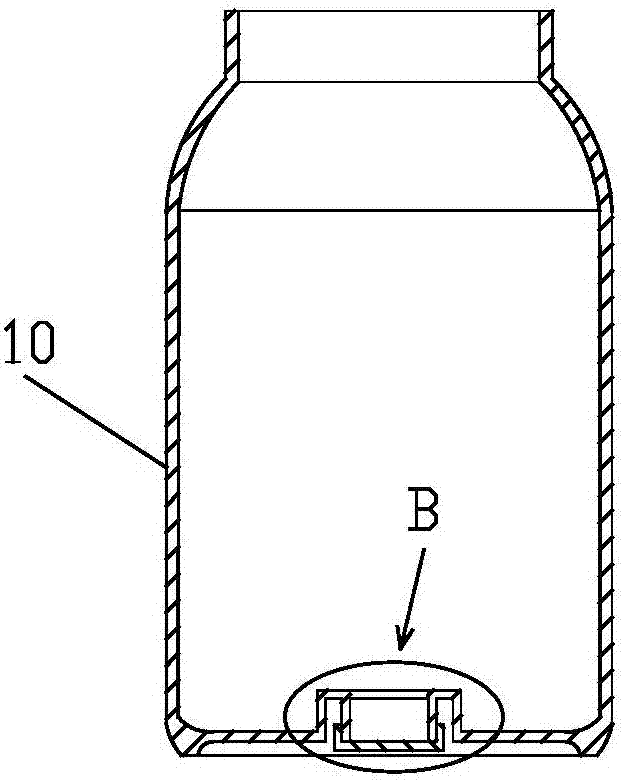

[0039] Toner bottle provided by the invention is as figure 2 , 3, shown in 6, a kind of novel toner bottle that is easy to add powder comprises bottle body 10 and powder adding head 20, and the bottle bottom of bottle body 10 is provided with for bar shape (powder adding device) inserts in the bottle body 10 The insertion part is in a blocked state before the insertion part is inserted into the strip. The bar mentioned above can be any one of rod material, sheet material, pipe material, plate material, and its effect is when adding powder, inserts in the toner bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com